Soda Water Filling Machine Solution

Brief Introduction

Soda Can Filling Machine adopts isobaric pressure filling system which is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small brewery and medium beverage plant

Machine Speed: 300-24000 CPH

Soda Glass Bottle Filling Machine

Soda Glass Bottle Filling Machine isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree).

Cap capping machine is qualified for Chinese seaming standard, and no air leakage at all. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too.

Machine Speed: 300-36000 BPH

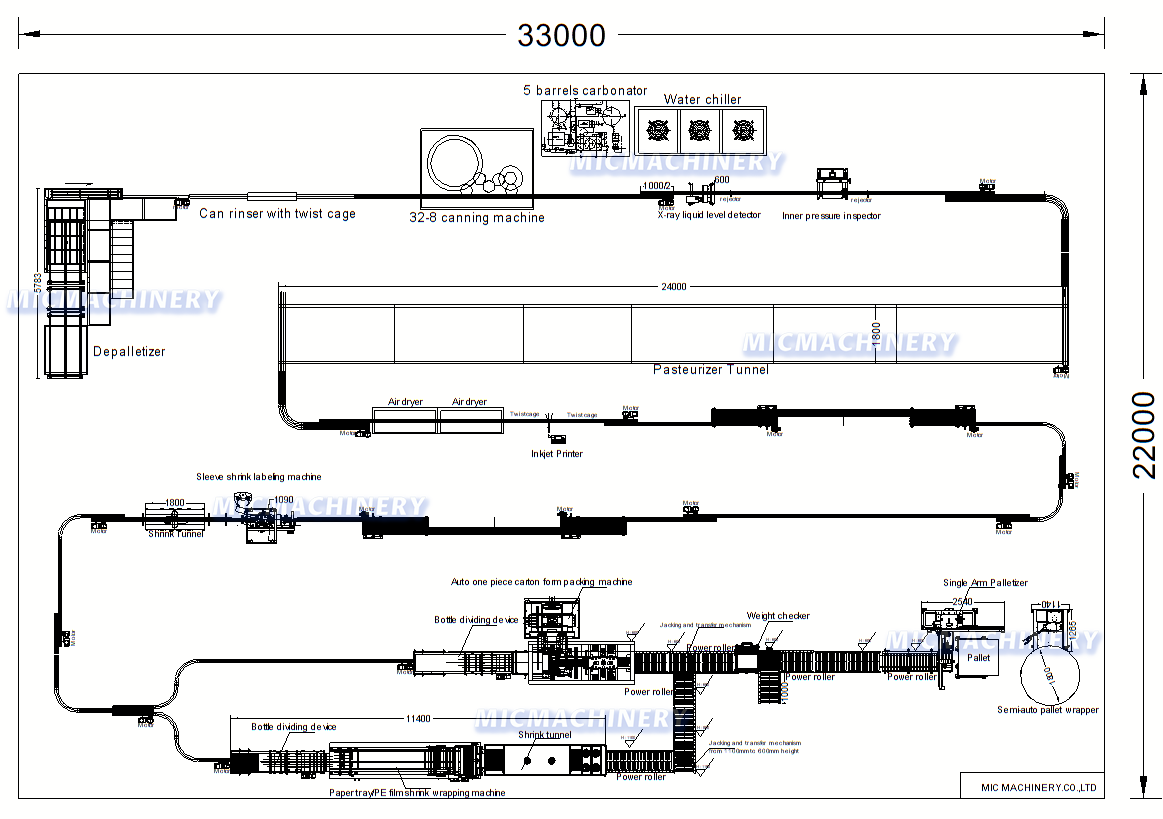

1.The stacking machine unloads the can or bottle

2.Can flip and rinse with twist cage

3.Can or bottle filling and capping station

4.Then X-rays are taken to detect the fluid level

5.Test the pressure in the can or bottle

6.The can or bottle goes into the tunnel, raising the temperature of the can

7.Can or bottle enter the air drying system to keep the can dry

8.Stamp the date on the can or bottle

9.Can or bottle shrink sleeve labeling station

10.Can or bottle carton packing station or film shrink wrapping machine

11.Place the packed beer can or bottle carton on a tray for transport and winding

| Complete Full Automatic 3-in-1 Soda Water Filling Machine |

Water/Soda |

|

Bottle Material |

Bottle Shape |

Filling Volume |

Filling Level (mm) |

Cap Type |

|

Glass Bottle |

Round Bottle |

200-2000ml |

Distance from bottle neck according request |

Screw cap Crown cap |

| Plastic Can | Round Can | 100-1000ml |

Distance from can neck according request |

Ring Pull Type Stay On Tab |

|

Adjustable specifications of the bottle, can type |

Customers need to buy additional change-over parts for the different bottles or cans. If using square bottles or cans, then bottle or can separating system will be added. |

|

Carbonated Drink Preparation |

Syrup melter / Mixing machine / Filter / CO2 Filter / CO2 Mixer ...../td> |

|

Filling Precision |

Washing bottle - CO2 into bottle - Vacuum - CO2 - Vacuum - Filling Beer - Capping |

|

Container Label & Control Mode |

Packing System |

Min, Spec. |

Palletizing System |

|

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic |

Manual Film Shrinker Wrap Around Packer Packing Machine |

1*2 2*3 3*4 4*6 3*5 |

Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

|

User Ambient Conditions |

Temperature: 10~40℃ Humidity: No dew |

|

User Electrical Supply Specification |

Voltage: 380V±5% 3phase Frequency: 50HZ±1% |

Soda Filling Machine adopts isobaric pressure filling system which is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius) It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss

MIC 18-1 Soda Can Filling Machine

Soda Can Filling Machine is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and seaming part is the overall designed, in order to ensure that both the absolute synchronization and coordination.

MIC 18-6 Automatic Soda Filling Machine

Automatic Soda Filling Machine has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small brewery and medium beverage plant

MIC 24-6 Soda Aluminum Can Filling Machine

Soda Aluminum Can Filling Machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control, no can no filling and so on. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all.

MIC 32-8 Soda Can Packaging Machine

Soda Can Packaging Machine Isobaric filling system, controlled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degrees Celsius).

MIC 40-10 Soda Canning Machine

Soda Canning Machine Aluminum can and metal can are both available working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase.

MIC 12-12-1 Soda Bottle Filling Machine

Soda Bottle Filling Machine are the aseptic filling equipment for the pure beer, designed and developed on the basis of introducing the technology from Germany and combining the features in the production industry of pure beer in China. The lift of liquid tank, capping heads and control ring is electric to adapt to different height bottles.

MIC 18-18-1 Soda Bottling Filling Machine

Soda Bottling Filling Machine is of good reliability of mechanical operation, perfect functions in rinsing, filling, capping, disinfecting and sterilizing, realizing filling the sterile beer into the sterile container in a sterile environment. This machine equips automatic lubrication device.Equip automatic washing device for broken bottles.

MIC 18-18-6 Soda Bottling Equipment

Soda Bottling Equipment Cooperation with transducer of main machine makes the bottle running smoothly and reliably, it is convenient to operate with high auto because of every part of machine is inspected to run by photoelectric detector. The machine is idea-preferred equipment for beverage makers.

MIC 24-24-6 Glass Bottle Soda Filling Machine

Glass Bottle Soda Filling Machine About machine automation, we are able to do what client required. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. Consider of product various ability, we are able to make machine for replace air from the can package.

MIC 32-32-10 Soda Gas Filling Machine

Soda Gas Filling Machine The machine is rotary design, Used for the production of various kinds of beer. This machine use pressure filling, liquid surface positioning. The machine for automatic control. Through the touch screen to operate the machine. It is applied to glass bottle and multifunctional which can be used for washing, filling and capping.

MIC-20P Plastic Bottle Shrink Packing Machine

Plastic Bottle Shrink Packing Machine rotation drove by servo motor, adopt to synchronous belt and chain rotation assembly method, ensure rotation harmony, the place that adopt to chain ration all add protection covet and lubricate device, ensure worker safe and circumstance clean.

MIC-10B Shrink Packaging Machine Manufacturer

Shrink Packaging Machine Manufacturer Specially designed for packaging production line of beer, beverage, pure water, fruit juice, dairy products, etc. With full automatic functions of bottle transfer and arrange, membrane packing, sealing and cut, shrinkage, cooling and shaping, etc.

MIC-15B Seal And Shrink Packaging Machine

Seal And Shrink Packaging Machine Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal. The quick seal cooling structure guarantee that the seal has a higher strength even if under high speed production condition.

MIC-20B Automatic Linear Wrap Packing Machine

Automatic Linear Wrap Packing Machine all the transfer system is controlled by frequency changing devices. With stable and smooth transfer speed. Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

Shrink Wrap Machine shape is simple and beautiful, its structure is novel and unique, and its maintenance is convenient.

The whole machine adopts energy-saving technology design, saving 35% energy consumption, low carbon and environmental protection.

MIC Autopack Shrink Wrapping Machine

Autopack Shrink Wrapping Machine Adopt with PLC automatic program circulation control with stable and reliable performance. The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

MIC-10C Case Packing Machine Manufacturers

Case Packing Machine Manufacturers Small space occupation, precision and durable parts provide the gaurantee for stable running, long life, and high efficiency.

Easy operation, machine can be used individually and combined with the packaging line.

MIC-15C Automatic Case Packer Machine

Automatic Case Packer Machine is reliable in operation: This machine is realized by the servo to pick up and release the product. Through the mechanical operation, pneumatic and electric control, the product can be accurately and reliably picked up from the box holder with a suction cup into the carton.

Automated Case Packer Bottle are separated to multi channel at conveyor, and then group by bottle separate fracture evenly. Bottle are grouped , then drop to cardboard via bottle drop fracture. At drop fracture with bottle and cardboard fall procedure, via one group of form block board, then card board fold to carton form.

Pallet Winding Machine motor, electric wire, chain device such as a dangerous all build.To ensure the safety of operating personnel. New 360 arc column design, concise and easy appearance. PLC programmable control, winding program is optional. Optional multi-function man-machine interface touch screen display system, real-time display equipment running status

MIC PET Bottle Blowing Machine

PET Bottle Blowing Machine is suitable for producing PET plastic containers and bottles in all shapes.

And can produce PET containers including the bottles for kinds of drink , soybean, vinegar, and pesticide (less than 10liters) according to the different bottle shape and diameter

Blow-drying Machine blow-dryer adopts advanced air knife technology with stable performance, low temperature operation, high visibility and good blow-drying effect. It is suitable for medium and high speed production line. Low energy consumption, it is the most ideal blow-drying tool for liquor packaging line.

MIC Plastic Empty Depalletizer Cans

Plastic Empty Depalletizer Cans is mainly used for stacking various Aluminum Cans, Tin Cans, PET Cans,Glass bottle, etc.and sta. The low-position box takes up less space and has a large production capacity. The whole machine is controlled by PLC, fully automatic operation.

MIC Carbonated Drink Mixing Machine

Carbonated Drink Mixing Machine The pre-cooled and pre-carbonized liquid flows through the inlet valve into the pot, in which, there is carbonic acid gas as well. The liquid flows out the groove and turns into a liquid curtain for better cooling and good carbonic acid gas absorption. Finally, the treated beverage liquid, powered by the carbonic acid gas pressure, flows into the filling machine.

MIC Pasteurization Machine Beer Tunnel Pasteurizer

Pasteurization Machine Beer Tunnel Pasteurizer which is a method of processing containers that have already been filled. The unprocessed product is poured into the container, the container is sealed, and then conveyed by the conveyor belt into the inside of the tunnel pasteurizer.

MIC Liquid Nitrogen Dosing Machine

Liquid Nitrogen Dosing Machine could control dosing volume accurately, no-container-no-liquid dosing, small size, easy installation and could coordinate with any filling production line. Control system comprises Siemens PLC and touch screen, all pipes adopt vacuum heat-insulated pipes which could ensure minimum consumption of liquid nitrogen and no frosting operation condition.

MIC X-Ray Liquid Level Detection Machine

X-Ray Liquid Level Detection Machine Through the installation of automated testing equipment, to achieve the quality control of the packaging aspects, and real-time defective products removed in the event of abnormal production failure, a sound alarm design, the scene can promptly notify the operator, the fault in time to contact, ensure that Productivity.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment