Aseptic Cold Filling Machine Manufacturer

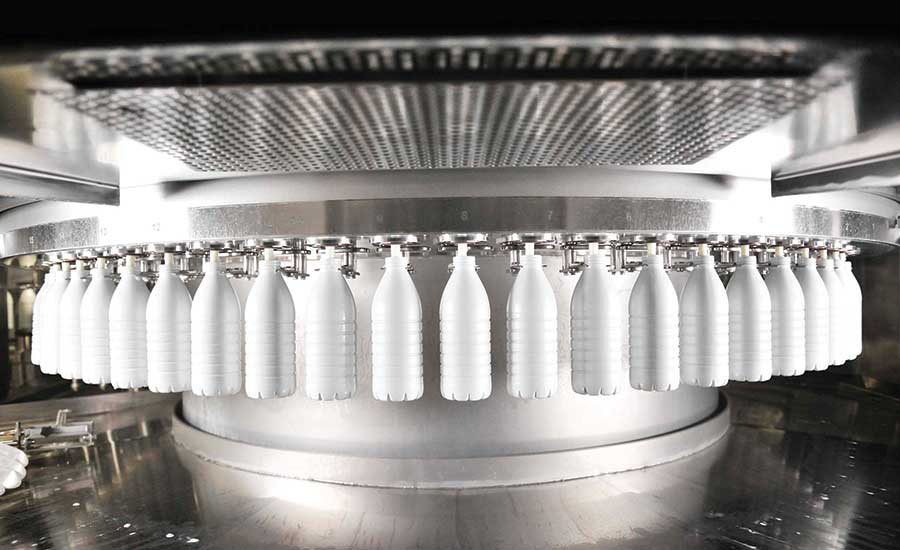

Zhangjiagang Mic Machinery offers advanced aseptic cold filling machines designed for safe, contamination-free filling of beverages without the need for high-temperature treatment. Perfect for sensitive products like juice, dairy, plant-based drinks, and probiotic beverages, our systems ensure shelf-stable results while preserving taste, color, and nutritional content.

Our aseptic filling solutions are built with complete sterilization systems for bottles, caps, and the filling environment, making them ideal for producers demanding ultra-clean production lines with extended shelf life guarantees.

What Is an Aseptic Cold Filling Machine?

An aseptic cold filling machine is used to fill sterile beverages into pre-sterilized containers under aseptic (germ-free) conditions, without requiring hot filling. This technology helps maintain the original flavor and nutrition of the product, while reducing energy consumption and packaging deformation.

Our machines integrate sterilizing tunnels, cleanroom enclosures, air filtration, and CIP/SIP systems to create a Class 100 aseptic zone that meets international food safety standards.

Ideal for Aseptic Filling:

Fruit Juices (with or without pulp)

Dairy-Based Drinks (milk, yogurt drinks)

Plant-Based Beverages (soy, oat, almond milk)

Nutritional & Functional Beverages

Cold Brew Coffee & Tea

Probiotic Drinks

Supports PET, HDPE, and multilayer bottles from 200ml to 2L+.

Key Features

Complete Aseptic Design – Filling zone with positive-pressure HEPA filters

Bottle & Cap Sterilization – Peracetic acid or H₂O₂ spray and UV systems

Non-Contact Filling Valves – Hygienic, fast, and drip-free

Servo Control System – Accurate volume control and gentle handling

CIP & SIP Capabilities – Full automatic cleaning and sterilization

Class 100 Clean Area – Controlled environment for sensitive drinks

Flexible Bottle Handling – Tool-free format changeover

Intelligence Meets Efficiency

With an advanced Siemens/Delta PLC system and multilingual HMI, our machines allow operators to monitor and adjust all parameters, including filling speed, liquid level, sterilization cycles, and temperature. Remote access and diagnostics help technicians troubleshoot from anywhere.

The intuitive control system also logs production data for quality assurance, traceability, and predictive maintenance.

Proven Performance Across the Globe

Zhangjiagang Mic Machinery has delivered aseptic filling lines to over 60 countries, serving global leaders in dairy, juice, and specialty beverage industries. Our team of engineers provides layout planning, commissioning, training, and after-sales support to ensure successful long-term operation.

From South America to Southeast Asia, our machines run daily in high-output factories producing sterile, shelf-stable drinks without preservatives.

Start Your Aseptic Beverage Line Today

Ready to improve product stability and hygiene? Zhangjiagang Mic Machinery delivers certified, high-performance aseptic cold filling machines that help brands extend shelf life while protecting product quality. Whether you're filling milk, juice, or plant-based drinks—our sterile technology delivers the results you need.

Contact us now for technical consultation, factory layout planning, or to get a quote on your aseptic filling project.