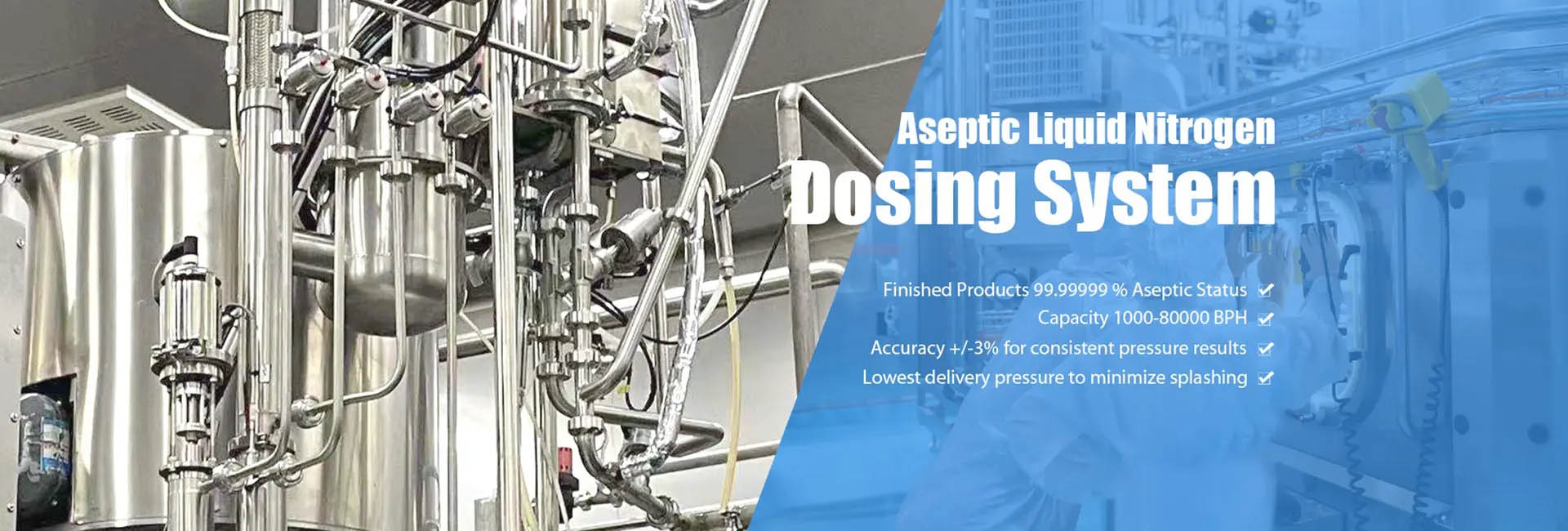

Aseptic Liquid Nitrogen Dosing Machine Manufacturer

Zhangjiagang Mic Machinery specializes in manufacturing high-performance aseptic liquid nitrogen dosing machines designed for ultra-clean production environments. Perfect for UHT milk, cold brew coffee, juice, and sterile beverages, our dosing system ensures oxygen reduction, shelf life extension, and can/bottle pressurization—without compromising sterility.

Built for cleanroom compatibility and high-speed production lines, this machine is your go-to solution for aseptic packaging systems.

Technical Introduction to Aseptic Liquid Nitrogen Dosing Machines and Their Performance

In modern food and beverage production, maintaining product integrity and extending shelf life are critical goals. An aseptic liquid nitrogen dosing machine plays a key role in achieving these objectives by precisely introducing liquid nitrogen into containers, ensuring product preservation and reducing oxygen levels. This article will focus on the performance, advantages, and applications of the aseptic liquid nitrogen dosing machine, explaining why it is a vital component for industries such as food and beverage, pharmaceuticals, and packaging.

Aseptic Liquid Nitrogen Dosing Machine

Performance and Benefits

Additionally, in carbonated beverage production, liquid nitrogen creates internal pressure in non-carbonated liquids, allowing the container to retain its shape and structure during storage and transportation. This is especially important for lightweight packaging materials, such as plastic bottles and thin aluminum cans, which might otherwise deform under external pressure.

Aseptic Processing and Safety

Applications

• Beverages: Carbonated and non-carbonated beverages, juices, and bottled water benefit from nitrogen dosing to preserve taste and extend shelf life.

• Pharmaceuticals: In pharmaceutical manufacturing, liquid nitrogen dosing is used to maintain sterile conditions and protect sensitive products from oxygen exposure.

• Canned Foods: Canned products such as soups, vegetables, and fruit juices often use nitrogen dosing to remove oxygen and maintain the integrity of the packaging.

Conclusion