Machine Application

1. Versatility Tailored to Your Needs:

Our mineral water bottling machines are crafted for versatility. Whether you operate a large-scale facility or a smaller operation, our machines adapt seamlessly, providing efficient solutions for packaging still, sparkling, or flavored mineral water.

2. Compact Efficiency for Small-Scale Excellence:

Recognizing the diversity of the market, our water bottle packing machines include compact solutions designed specifically for small-scale operations. These machines may be smaller in size but deliver unwavering efficiency, making top-tier technology accessible to businesses of all sizes.

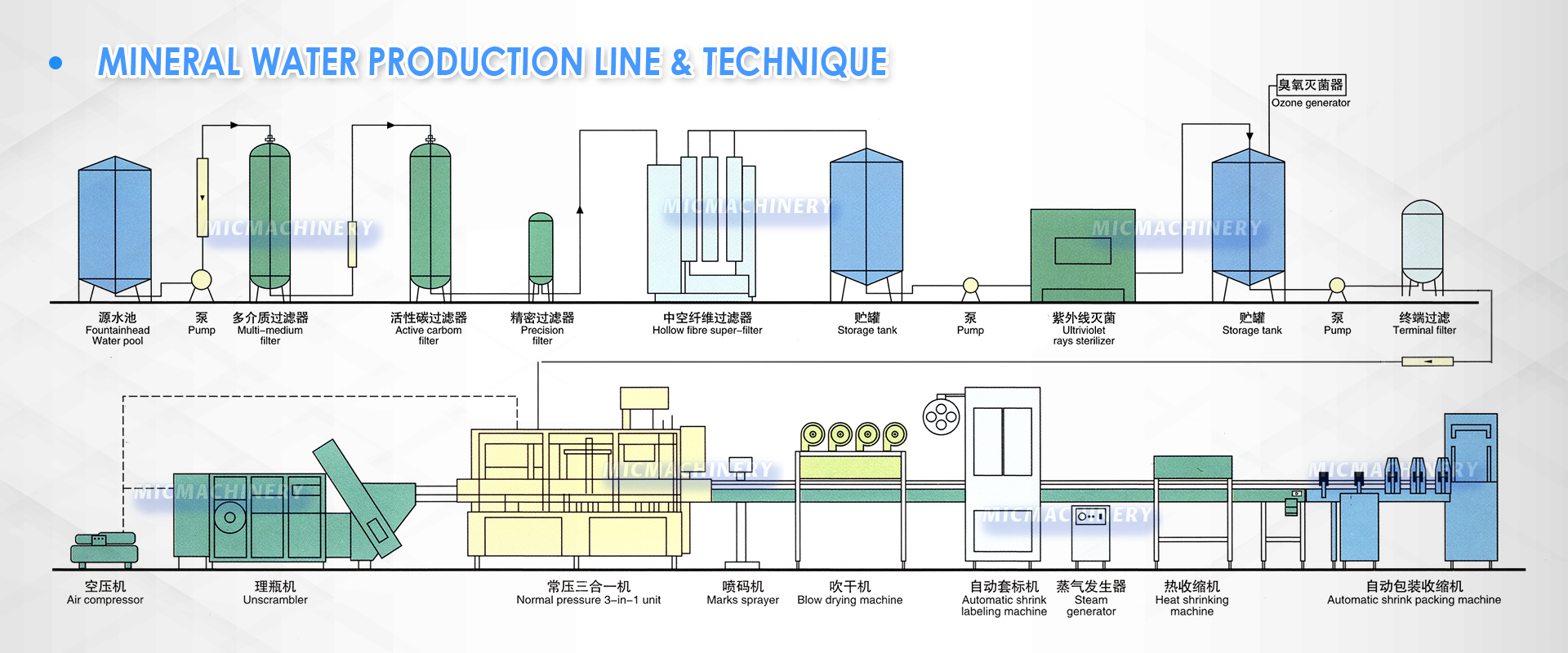

Machine Workflow

1. Adaptable Configurations for Streamlined Processes:

The hallmark of Mic Machinery's mineral water filling equipment lies in its adaptive configurations. These machines facilitate easy adjustments to accommodate various bottle sizes, shapes, and materials, ensuring a streamlined workflow that simplifies product diversification.

2. High-Speed Operations for Timely Deliveries:

Engineered for efficiency, our machines operate at high speed, contributing to an efficient workflow. Automation reduces manual labor, minimizes downtime, and ensures your mineral water products reach the market with the promptness essential in a dynamic industry.

Machine Core Technology

1. Precision Liquid Filling Mechanism:

Central to our mineral water bottling machines is a precision liquid filling mechanism. This cutting-edge technology guarantees accurate liquid levels in every bottle, maintaining uniformity and adhering to the rigorous quality standards set by the mineral water industry.

2. Intelligent Sealing and Capping Technology:

We employs intelligent sealing and capping technology, ensuring secure and tamper-evident closures. This not only preserves the purity of your mineral water but also instills confidence in consumers, underlining the commitment to product integrity.

3. Smart Automation and Control Systems:

Embrace efficiency with our smart automation and control systems. These technologies optimize the entire bottling process, from liquid filling to capping. Automation reduces the risk of errors, ensuring a seamless and reliable packaging process.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Step into a new era of mineral water production with Mic Machinery. As a leader in technological innovation, we present a range of mineral water filling machines that redefine efficiency, precision, and adaptability. Here's why choosing Mic Machinery means choosing a partner dedicated to enhancing your mineral water bottling operations.

Technological Excellence:

1. Leading-Edge Designs:

At Mic Machinery, we pride ourselves on delivering mineral water bottling machines at the forefront of technological advancement. Our designs embody innovation, ensuring that your production process is not just streamlined but truly state-of-the-art.

2. Compact Solutions for Every Scale:

For businesses of all sizes, we offer compact water bottle packing machines. These solutions are crafted with efficiency in mind, providing the same level of excellence in a smaller package, making top-tier technology accessible to all.

Precision in Every Drop:

1. Small Bottle Packing Precision:

Recognizing the demand for precision, especially with smaller bottles, our machines are engineered to guarantee accurate liquid levels, secure seals, and efficient packaging. Consistency is the hallmark of Mic Machinery's small bottle packing expertise.

2. Configurations Tailored to You:

Adaptability is key in a dynamic industry. Our machines feature customizable configurations, effortlessly adjusting to accommodate various bottle sizes, shapes, and materials. Stay ahead of market trends with the flexibility provided by Mic Machinery.

Quality Assurance, Always:

1. Stringent Testing Standards:

Quality isn't a promise; it's a guarantee. Every mineral water bottling machine undergoes rigorous testing to not only meet industry standards but exceed them. Trust Mic Machinery for unwavering commitment to quality assurance.

2. Customer-Centric Support:

Your success is our focus. Our dedicated support team is ready to assist you at every step – from selecting the perfect machine for your needs to providing ongoing support for seamless integration into your production line.

Choosing Mic Machinery Means Choosing Excellence:

1. Innovation for Every Scale:

Mic Machinery introduces innovation to small-scale efficiency. Our water bottle packing machines are designed to empower your business, ensuring that you not only compete but thrive in a dynamic market.

2. Versatility for Unique Branding:

Embrace diverse packaging designs effortlessly. Our machines offer versatility, providing the flexibility you need for creative branding, meeting market demands, and staying ahead of industry trends.

In conclusion, Mic Machinery isn't just a provider of mineral water bottling machines; we are your strategic ally in advancing your production capabilities. Choose innovation, choose precision, and choose efficiency with Mic Machinery. Connect with us today to embark on a journey of technological excellence in mineral water bottling.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment