Precision Filling Solutions for Water, Juice, Soda, and More

Our Beverage Bottling Machine is a cutting-edge solution for automated filling, capping, and sealing of beverages in bottles. Designed to handle a wide range of drinks—from still water and juices to carbonated soft drinks—this machine ensures speed, hygiene, and consistent performance, making it ideal for modern bottling operations.

What is a Beverage Bottling Machine?

A Beverage Bottling Machine is an industrial-grade system that automates the process of filling liquid beverages into PET or glass bottles. It combines multiple stages including bottle rinsing, precision filling, capping, and sometimes labeling into one streamlined unit. These machines are widely used in beverage plants for efficiently processing a variety of drinks while preserving product quality.

Whether you produce flavored waters, teas, sodas, energy drinks, or fruit juices, a beverage bottling machine can dramatically boost your production efficiency and reduce labor costs.

Why Choose Our Beverage Bottling Machine?

-

Precision Filling: Ensures exact volume in every bottle to maintain brand quality and reduce product loss.

-

Clean in Place (CIP): Optional automatic cleaning system ensures hygiene without disassembling the machine.

-

Compact Design: Space-efficient layout for easy installation in various factory sizes.

-

Fast Changeover: Quick adjustment for different bottle sizes and drink types.

-

Reliable Operation: Built for continuous production with minimal maintenance needs.

-

Cost-Effective: Saves on labor and operational costs through high-speed automation.

More Gas Drink Bottle Model And Speed Click

|

Model |

MIC12-12-1 |

MIC18-18-1 |

MIC18-18-6 |

MIC24-24-6 |

MIC24-24-8 |

MIC32-32-8 |

MIC semi automatic |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water, And So On |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, Pet Bottle Etc |

||||||

|

Speed |

300-1500BPH |

1000-2500BPH |

2000-4000BPH |

4000BPH |

2000-6000BPH |

4800-7500BPH |

200-800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

|

Power |

|

|

2.2kw |

1.5kw |

1.5kw |

5.0kw |

0.3kw |

|

Size |

|

|

2.5*1.9*2.3 (M) |

2.2*1.8*2.55 (M) |

2.5*1.4*2.5 (M) |

3.4*2.5*2.3 (M) |

2.0*0.7*2.0 (M) |

|

Weight |

|

|

3500KG |

3500KG |

4500KG |

10000KG |

150KG |

More Non Gas Drink Bottle Model And Speed Click

|

Model |

MIC 12-1 |

MIC 8-8-3 |

MIC 14-12-5 |

MIC 18-18-6 |

MIC 18-18-6 |

MIC 24-18-6 |

MIC Linear |

|

Application |

Juice, cold coffee, herbal tea, non-carbonated drinks and so on |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, Pet Bottle Etc |

||||||

|

Speed |

500-2000BPH |

2000-2500BPH |

3000-5000BPH |

8000-15000BPH |

8000-10000BPH |

10000-13000BPH |

1800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

Beverage Bottling Machine Manufacturer

- High-Speed Filling

- Versatile Beverage Compatibility

- Advanced Filling Systems

- Automated Capping

- Touchscreen PLC Interface

- Modular and Customizable

Technical Introduction to Beverage Bottling Machines

Beverage Bottling Machine

A beverage bottling machine is designed to fill, cap, and sometimes label bottles in a streamlined process. These machines are engineered for high-speed operations and can handle various bottle sizes and shapes, ensuring precise filling to minimize waste. The performance of a beverage bottling machine directly impacts production efficiency, as modern machines incorporate advanced technologies like automated controls and sensor systems to enhance accuracy and speed.

Beverage Bottling Equipment

Beverage bottling equipment includes a range of machinery used in the bottling process, such as rinsers, fillers, cappers, and labeling machines. This equipment is integral to creating an efficient production line that can adapt to different beverage types and market demands. By utilizing high-performance beverage bottling equipment, manufacturers can improve workflow, reduce labor costs, and maintain stringent quality control standards.Beverage Bottle Filling Machine

The beverage bottle filling machine is a critical component of the bottling line, specifically designed to fill bottles with liquid products. These machines can be configured for various filling methods, including gravity, vacuum, and pressure filling, depending on the beverage being packaged. Their ability to handle carbonated and non-carbonated liquids while ensuring consistent filling levels is essential for maintaining product integrity. The performance of beverage bottle filling machines is vital for optimizing production rates and ensuring quality.

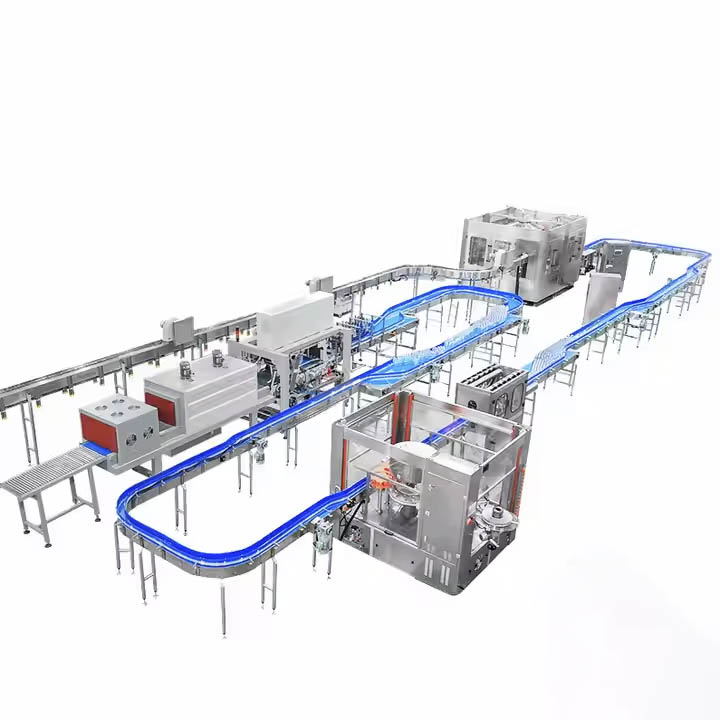

Beverage Bottling Line

A comprehensive beverage bottling line integrates all the necessary equipment for bottling operations, from filling to capping and labeling. This line enhances overall efficiency by allowing different stages of the bottling process to occur in rapid succession. By investing in a well-designed beverage bottling line, manufacturers can achieve higher throughput and streamline their operations, ultimately leading to reduced costs and improved product quality.

When considering investments in bottling machinery, understanding the real beverage soda bottling machine price is essential. Prices can vary significantly based on machine capabilities, production speed, and technology features. Manufacturers should assess their production needs and budget to find the best value while ensuring that the machinery meets performance and quality standards.

Conclusion

Investing in high-quality beverage bottling machines and beverage bottling equipment is critical for manufacturers looking to optimize their production processes. The integration of effective beverage bottle filling machines within a comprehensive beverage bottling line enhances operational efficiency and product consistency. By carefully evaluating the real beverage soda bottling machine price, beverage producers can make informed decisions that align with their production goals and market demands, ensuring successful operations in a competitive landscape.

The beverage bottling machine, or beverage bottle filling machine, is a specialized piece of equipment designed to automate and streamline the bottling process. It is a crucial component in beverage production facilities, ensuring the efficient and precise filling of various beverages into bottles. This versatile machine accommodates a wide range of beverages, including carbonated drinks, still beverages, juices, and more. Its primary function is to accurately measure and fill the desired quantity of liquid into bottles, while maintaining the integrity of carbonation levels for carbonated beverages.

Efficiency is a significant advantage of beverage bottling machines. These machines are equipped with advanced automation features that enhance productivity and reduce production time. The high-speed filling systems, synchronized capping mechanisms, and efficient conveyors optimize the overall production process, enabling beverage manufacturers to meet high-volume demands and tight deadlines. By automating repetitive tasks, beverage bottling machines reduce labor costs and minimize the risk of human errors, resulting in higher output and improved efficiency.

For the carbonated beverage industry, maintaining the desired carbonation levels is crucial to deliver a refreshing drinking experience. Carbonated beverage bottling equipment, including beverage bottling machines, incorporates specialized technologies to preserve the carbonation integrity throughout the bottling process. These machines employ precise pressure controls, carbon dioxide (CO2) management systems, and filling techniques that prevent excessive foaming or loss of carbonation. By ensuring consistency in carbonation levels, the bottling machine guarantees that carbonated beverages retain their refreshing effervescence and taste.

Another advantage of beverage bottling machines is their versatility. These machines are designed to accommodate different bottle sizes, shapes, and materials, catering to diverse packaging requirements. Whether it's glass bottles, PET bottles, aluminum cans, or other packaging formats, the beverage bottling machine can be easily adjusted to handle various containers. This flexibility allows beverage manufacturers to adapt to market trends, consumer preferences, and specific product launches, enabling efficient production and packaging customization.