Mechanical Principle

1. Rotary Precision and Pneumatic Control:

Precision is paramount in beer canning lines, where rotary mechanisms and pneumatic systems collaborate to ensure swift and precise canning. From depalletizing to sealing, these lines guarantee airtight perfection, showcasing a mechanical dance of accuracy.

2. Versatile Gravity and Pressure Mechanisms:

Beer filling lines embrace versatility with gravity or pressure-based filling mechanisms. Adapting to diverse brew conditions, these lines utilize precision-controlled valves and sensors to maintain liquid accuracy, minimizing wastage and maximizing efficiency.

3. Adaptability and Customization:

Small beer bottling lines thrive on adaptability. With customizable conveyor systems and filling heads, these lines seamlessly integrate into varied brewery setups. Gravity-fed or pressure-assisted, the filling and capping mechanisms epitomize precision for small-scale craft brewing.

Machine Application

1. Efficient High-Speed Canning:

Beer canning lines excel in large-scale productions, ensuring efficient high-speed canning processes. Ideal for breweries with significant output demands, these lines effortlessly handle various can sizes, meeting market preferences.

2. Versatility in Handling Diverse Brews:

Beer filling lines shine in versatility, accommodating different bottle sizes and styles. Adapting to various beer styles, from traditional ales to experimental brews, these lines cater to the dynamic nature of craft brewing.

3. Tailored Solution for Boutique Breweries:

Small beer bottling lines are the tailored solution for boutique breweries. Designed for flexible integration and space efficiency, they cater to smaller batches, offering a reliable packaging solution for craft brewers.

Machine Advantages

1. Unmatched Efficiency in Precision:

The primary advantage of beer canning lines lies in their unmatched efficiency. With rotary precision and pneumatic control, these lines consistently deliver airtight seals, ensuring the beer's quality is preserved.

2. Consistent Filling Precision:

Beer filling lines offer an advantage in adaptability and consistent precision. Whether handling carbonated brews or unique ingredients, the precision-controlled valves minimize wastage, contributing to cost-effective and reliable beer packaging.

3. Customization and Adaptability:

Small beer bottling lines stand out for their customization. Tailored for unique brewing requirements, these lines offer adaptability to handle smaller batches efficiently, combining flexibility with precision.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1000-1500CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 480CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 1800CPH

Speed: 800-1500BPH

Speed: 3000-5000BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Brewery Optimization through Advanced Technology:

1. Beer Canning Line: A Ballet of Precision and Efficiency

In the grand tapestry of brewing, our beer canning lines emerge as choreographers of a ballet that marries precision with efficiency. Behold the seamless dance of technology and craftsmanship as our beer canning lines orchestrate the swift and accurate transition from the filling chamber to the sealing station. Each can emerges as a testament to perfection, a symphony of consistency that positions your brewery at the forefront of delivering an unparalleled beer experience.

2. Beer Filling Line: Crafting Excellence with Every Drop

At the nexus of brewing lies the delicate art of filling, and our beer filling lines are virtuosos in this symphony of craft. Purposefully designed for breweries of all sizes, these beer filling lines embody a harmonious blend of efficiency and versatility. Revel in the freedom to accommodate an array of bottle sizes seamlessly, transitioning between stages with the grace of a maestro. Our beer filling lines transcend functionality; they are canvases for your craft, allowing the intricate nuances of brewing to resonate with every drop.

3. Small Beer Bottling Line: A Canvas for Artisanal Expression

For the vanguards of craft brewing, our small beer bottling lines are an ode to the spirit of artisanal expression. Compact yet resilient, these small beer bottling lines redefine space optimization without compromising on the intricate art of bottling. Experience the liberation to experiment with unique brews, with each bottle becoming a canvas that celebrates the marriage of tradition and innovation.

Why Mic Machinery Stands Out:

1. Innovation and Technology at the Pinnacle:

2. Tailored Excellence for Unique Breweries:

We celebrate the diversity of each brewery, and our beer production lines echo this sentiment. Far from standardized solutions, our offerings are bespoke, meticulously tailored to harmonize with the unique operational nuances and aspirations of your brewery, ensuring a perfect fit that amplifies your distinct brewing identity.

3. A Commitment to Unsurpassed Quality:

Quality is not just a benchmark; it is our unwavering commitment. Our beer production lines undergo rigorous testing processes, adhering to the highest industry standards. The result is not just reliability but a promise of consistency, ensuring each production cycle is an epitome of uncompromising quality.

Mic Machinery extends an earnest invitation to breweries worldwide to embark on an odyssey of brewing mastery. Our beer canning lines, beer filling lines, and small beer bottling lines are not mere instruments; they are conductors of an epic symphony that transcends time and tradition. Partner with us as we redefine the brewing narrative, shaping the future of the industry—one production line at a time. Here's to the magnum opus of brewing, a saga where tradition and innovation coalesce in every drop. Cheers to the limitless artistry of brewing!

- Beer filling machine solution

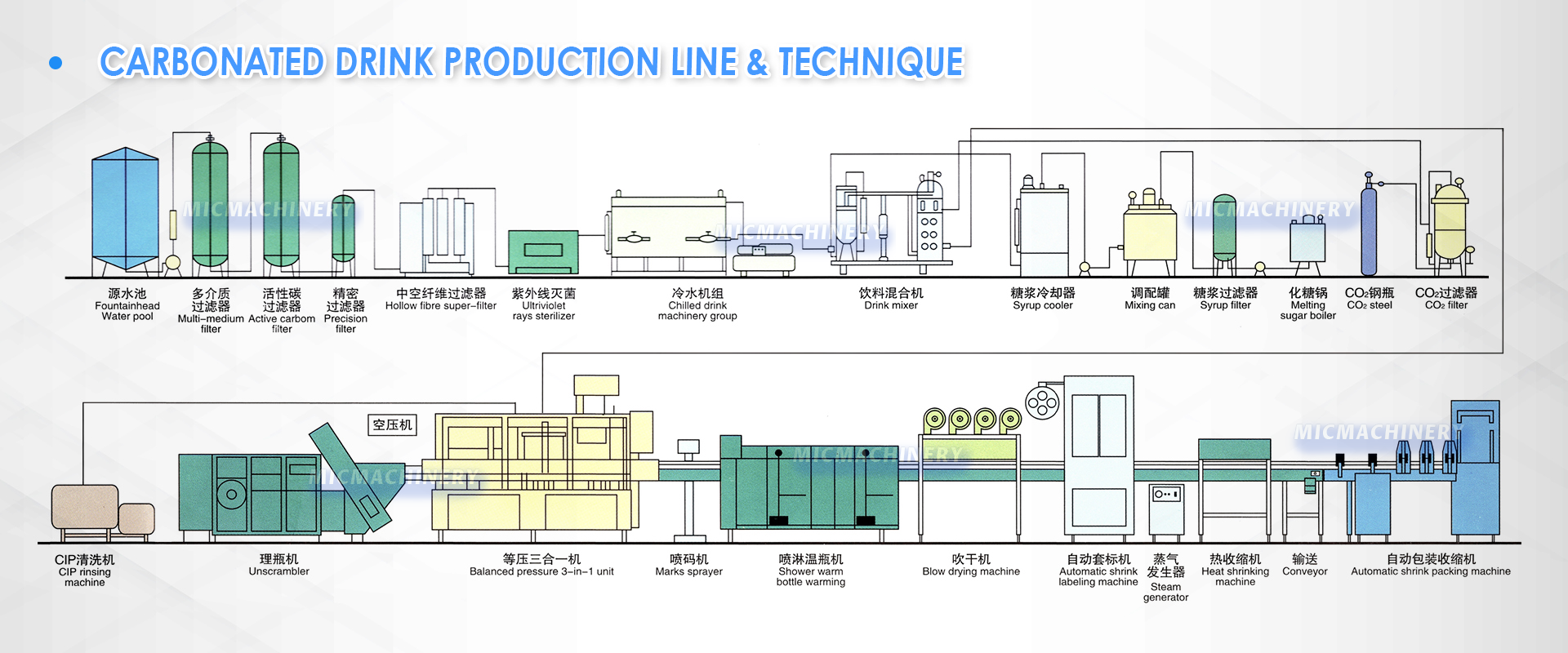

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment