- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

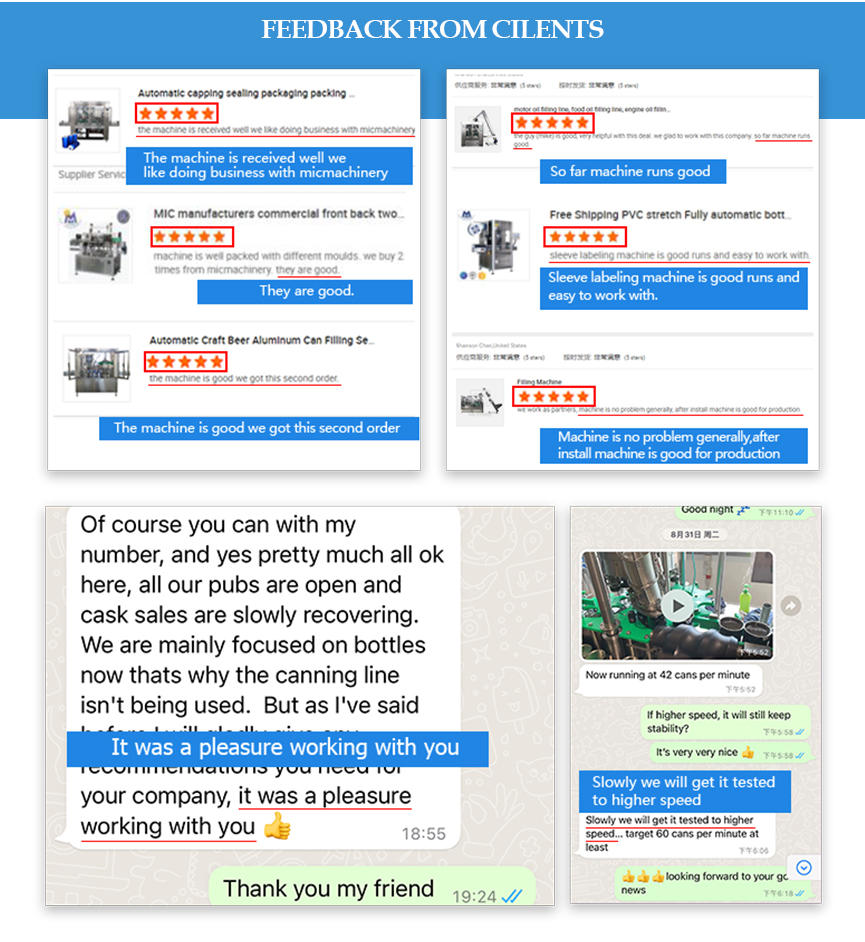

- Customer reviews: click on

Quality materials are used for this machine. Especially polished and sanitary steel is used for parts directly contacting the liquid. The machine is designed for various beverage productions. Besides the two-step carbonization, high CO2 content and low production temperature ensures the volume ratio of CO2 and 1L water to be 2.0-3.5.

Air Gauge

The pre-cooled and pre-carbonized liquid flows through the inlet valve into the pot, in which, there is carbonic acid gas as well. The liquid flows out the groove and turns into a liquid curtain for better cooling and good carbonic acid gas absorption. Finally, the treated beverage liquid, powered by the carbonic acid gas pressure, flows into the filling machine.

control panel

Quality materials are used for this machine. Especially polished and sanitary steel is used for parts directly contacting the liquid. The machine is designed for various beverage productions. Besides the two-step carbonization, high CO2 content and low production temperature ensures the volume ratio of CO2 and 1L water to be 2.0-3.5.

text text

|

Capability

|

carbonated drink 2T/H

|

|

Mixing ratio range of water to sugar

|

3:1--6:1

|

|

Product CO2 content

|

2.0-3.5

|

|

Product temperature

|

less than 4°C

|

|

Power consumption

|

about 5KW

|

|

Plate heating exchanger area

|

10m2

|

|

Overall size

|

1. (L*W *H) 1500*1200*2200 (mm)

|

|

Net weight

|

1500kg

|

|

Drink water (clear water after purification)

|

0.25--0.35MPa

|

|

Syrup

|

0.10--0.15MPa

|

|

Carbonic acid gas(CO2)

|

0.8--1.0MPa, purity 99.99%

|

|

Compressed air

|

0.6--0.8MPa

|

|

PLC

|

Mitsubishi

|

|

Low-voltage apparatus

|

Schneider

|

|

Touchscreen

|

WEINVIEW

|

|

Pneumatic equipment

|

Airtac

|

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment