- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

In modern manufacturing, the efficiency and accuracy of packaging processes are essential for meeting production goals and ensuring customer satisfaction. Case packing machines, including case packers and automated case packers, play a crucial role in optimizing these processes. Let's explore how these machines enhance performance and efficiency, focusing on their roles as case packing machines.

Maximizing Performance with Case Packing Machines

Efficiency Boost: Case packing machines streamline the packaging process by automating the placement of products into cases or containers. They operate swiftly and precisely, significantly reducing manual labor and packing time. Whether handling bottles, cartons, or other packaged goods, these machines optimize throughput and minimize bottlenecks in the production line.

Versatility: Case packers come in various configurations to accommodate different packaging formats, sizes, and types. They can handle a wide range of products, from food and beverages to household goods and pharmaceuticals. This versatility allows manufacturers to adapt their packaging processes to suit diverse product lines and production requirements.

Precision Engineering: Automated case packers are equipped with advanced technology and precision mechanisms to ensure accurate and consistent packing. They can handle fragile or irregularly shaped products with care, minimizing the risk of damage during the packing process. This precision is essential for maintaining product integrity and minimizing waste.

Importance of Case Packing Machines

Enhanced Efficiency: Case packers play a crucial role in enhancing overall production efficiency. By automating the packing process, these machines reduce labor costs and increase output, allowing manufacturers to meet growing demand while maintaining high-quality standards.

Optimized Workflow: Automated case packers integrate seamlessly into existing production lines, optimizing workflow and minimizing downtime. They can be programmed to work in tandem with other packaging equipment, such as fillers and sealers, ensuring a smooth and continuous packaging process.

Improved Productivity: With their high-speed operation and precision packing capabilities, case packers significantly increase productivity. They can handle large volumes of products efficiently, allowing manufacturers to fulfill orders quickly and effectively.

Conclusion

In the fast-paced world of manufacturing, case packing machines are indispensable tools for optimizing packaging processes. Whether as case packers or automated case packers, these machines offer enhanced efficiency, versatility, and precision, allowing manufacturers to meet production goals and deliver high-quality products to consumers. By investing in advanced case packing technology, manufacturers can streamline their operations, increase productivity, and stay competitive in today's market.

Major characteristics

1. Imported components, electric and pneumatic parts.

2.Vertical cardboard mechanical, add cardboards whenever necessary without stopping the machine.

3.Manually adjust for different cartons within allowable range, just takes 1~2 minutes.

4.Reasonable design, vacuum cup suck the cardboard, fold and seal the bottom.

5.Small space occupation, precision and durable parts provide the gaurantee for stable running, long life, and high efficiency.

6. with protection device for cutter installation to avoid being hurt.

7.Easy operation, machine can be used individually and combined with the packaging line.

◆ Automatic case packing machine

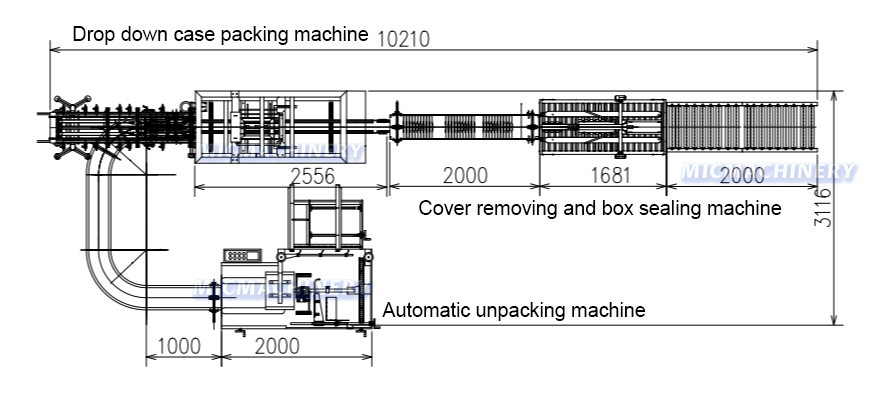

In the automatic packaging line, the case packer is the core of the entire system. The carton packing machine is used to complete transportation and packaging. It is a machine that packs finished products into cartons according to a certain arrangement. This type of boxing machine produced by our company is a drop-type automatic boxing machine, which can automatically shape and arrange the packaging, put it into the opened carton, and complete the tape sealing and other actions. This machine adopts a new type of combination The structure includes functional units such as unpacking and forming device, lane dividing and aligning device, filling device and sealing device, respectively, to complete the corresponding functional actions.

Major characteristics

1. According to the customer's packing and arrangement requirements, the products are automatically arranged and combined to reduce labor intensity and improve efficiency

2. When packing, the equipment will automatically open and position the top of the carton to ensure smooth packing and no worries about jams.

3. It has a wide range of applications, can meet the packing of products of various specifications, and is convenient to adjust

4. Realize product sorting and packing in the same station, which solves the problem of large volume and space occupation of conventional packing machines

5. Control mode: PLC+touch screen+standard control button+signal switch, divided into automatic/manual control mode

6. The fault point can be found through the touch screen, and troubleshooting is easy and simple

7. This machine is suitable for edible oil, daily chemical, beverage and food and other light industry industries, and has a wide range of applications

Carton sealing machine

◆ Major characteristics

1. Top to bottom Transmission belt, the main transmission mechanism is high-precision and low noise, make the belt life longer.

2. The length of the folded sealing belt's can be adjusted: 55mm, 65mm, 75mm

3. The machine has the alarm indicated system, automatic stop system when the door opening, these system keep safe for maintenance.

Conveyor

Technical Parameters

|

Carton size |

L260-535* W260-420*H130-330 |

|

Speed |

10 carton/min(according to the carton size) |

|

Dimension |

1950*1500*1450mm |

|

Power supply |

220V;50Hz |

|

Table high |

Min 600mm; Max 720mm |

|

Tape width |

45~72mm |

|

weight |

300kg |

|

Model |

ROY-10C |

|

Power supply |

380V,50/60Hz |

|

Power |

3.5kw |

|

Capacity |

500-600 case/hour |

|

Total weight |

1200kg |

|

Air consumption |

5-6kg/cm2 460L/min |

|

Packing speed |

20 cartons/min |

|

Tape width |

36~70mm |

|

Power supply |

220V 50Hz |

|

Power |

0.5kw |

|

Size |

2000*740*1400mm |

|

weight |

200kg |

Configuration

|

Name |

Model |

Amount |

Brand |

Origine |

|

Miniature circuit breaker |

4P C20 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

1P C10 |

1 |

Schneider |

France |

|

A.C.contactor |

E1810 |

1 |

Schneider |

France |

|

A.C.contactor |

E09104 |

3 |

Schneider |

France |

|

Emergency stop |

LAY7-11ZS/R |

1 |

Schneider |

France |

|

Switching power supply |

S8JC-Z05024C |

1 |

Schneider |

France |

|

Relay |

MY2NJ 24VDC |

1 |

Schneider |

France |

|

PLC |

SIMATIC S7-200 |

1 |

Siemens |

Germany |

|

Touch screen |

SMART 700 IE V3 |

1 |

Siemens |

Germany |

|

Frequency transformer |

SINAMICS V20 |

1 |

Siemens |

Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment