- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

One of the primary functions of the Liquid Nitrogen Dosing Machine is to ensure optimal nitrogen levels within packaged products, thereby extending shelf life and preserving freshness. This process, known as liquid nitrogen dosing, involves injecting liquid nitrogen into containers before sealing, effectively displacing oxygen and minimizing the risk of oxidation, spoilage, and degradation.

The dosing process is meticulously controlled by the machine, allowing for precise dosage adjustments tailored to the specific requirements of each product. Whether it's beverages, snacks, pharmaceuticals, or other perishable goods, the Liquid Nitrogen Dosing Machine offers customizable dosing parameters to meet the unique needs of various industries and applications.

For industries requiring strict adherence to aseptic standards, specialized variants such as the Aseptic Liquid Nitrogen Dosing Machine are available. These machines are designed to operate in sterile environments, ensuring that the dosing process maintains the integrity and safety of the packaged products without introducing contaminants.

Beyond its preservation capabilities, the Liquid Nitrogen Dosing Machine offers a range of additional benefits. By displacing oxygen with nitrogen, it helps prevent oxidation and preserve the flavor, texture, and nutritional value of packaged goods. This not only extends shelf life but also enhances product quality and customer satisfaction.

Furthermore, the dosing process facilitated by the machine contributes to sustainability efforts by reducing the need for preservatives and additives. By creating a nitrogen-rich atmosphere within containers, it minimizes reliance on chemical agents while maintaining product freshness and safety.

In addition to its technical prowess, the Liquid Nitrogen Dosing Machine is prized for its efficiency and reliability in production environments. With advanced automation features and intuitive controls, it seamlessly integrates into packaging lines, optimizing throughput and minimizing downtime.

In conclusion, the Liquid Nitrogen Dosing Machine represents a pinnacle of innovation in packaging technology. As a versatile nitrogen dosing machine capable of liquid nitrogen dosing and meeting aseptic standards, it offers unparalleled preservation capabilities while enhancing product quality and sustainability. With its precision dosing, efficiency, and reliability, it has become an indispensable asset for industries seeking to prolong shelf life, maintain freshness, and meet the evolving demands of modern consumers.

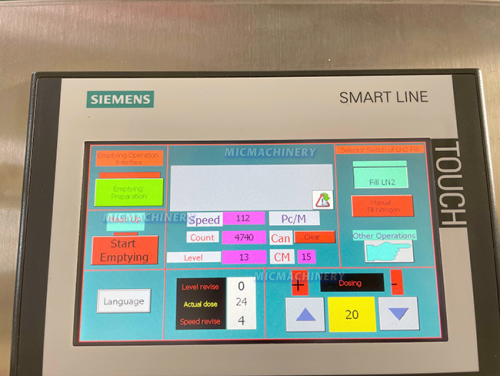

WYD-300 Liquid Nitrogen Dosing Machine is the latest liquid nitrogen dosing machine in China which uses the similar machines abroad for reference. It could control dosing volume accurately, no-container-no-liquid dosing, small size, easy installation and could coordinate with any filling production line. Control system comprises Siemens PLC and touch screen, all pipes adopt vacuum heat-insulated pipes which could ensure minimum consumption of liquid nitrogen and no frosting operation condition.

Liquid nitrogen gasify and volume expansion 700 times, extrude the air out and form vacuum in the can, increase the aluminum can/pet can internal pressure to prolong the canned beverage shelf life and keep good looking for better transportation and store.

Control system

Control system comprises Siemens PLC and touch screen, all pipes adopt vacuum heat-insulated pipes which could ensure minimum consumption of liquid nitrogen and no frosting operation condition.

Liquid nitrogen gasify and volume expansion 700 times, extrude the air out and form vacuum in the can, increase the aluminum can/pet can internal pressure to prolong the canned beverage shelf life and keep good looking for better transportation and store.

Liquid Nitrogen Dosing Machine is the latest liquid nitrogen dosing machine in China which uses the similar machines abroad for reference. It could control dosing volume accurately, no-container-no-liquid dosing, small size, easy installation and could coordinate with any filling production line

|

Technology Parameter

|

||||

|

Application

|

Beer, cold coffee, herbal tea, fruit juice, non-carbonated drinks and so on

|

|||

|

Package

|

Aluminum can, tin can, pet can, plastic bottle

|

|||

|

Production speed

|

30-300 cans/min, Set up continuous dosing speed

|

|||

|

Suitable size

|

180ml, 250ml, 330ml, 355ml, 500ml, 12oz, 16oz and so on

|

|||

|

Voltage

|

380V/50HZ/3Phase or 220V/50HZ/1Phase

|

|||

|

Weight

|

32KW

|

|||

|

Dimension

|

1300mm×750mm×450mm

|

|||

|

Main Configuration List

|

||||

|

PLC HMI

|

Siemens (Germany)

|

|||

|

Touch screen

|

Siemens (Germany)

|

|||

|

Solenoid valve

|

AirTAC (Taiwan, China)

|

|||

|

Proximity Switch

|

Omron (Japan)

|

|||

|

Temperature control

|

Omron (Japan)

|

|||

|

High speed dosing valve

|

MAC (USA)

|

|||

|

Dosing valve core

|

Germany

|

|||

|

Titanium filter stick

|

Germany

|

|||

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment