- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

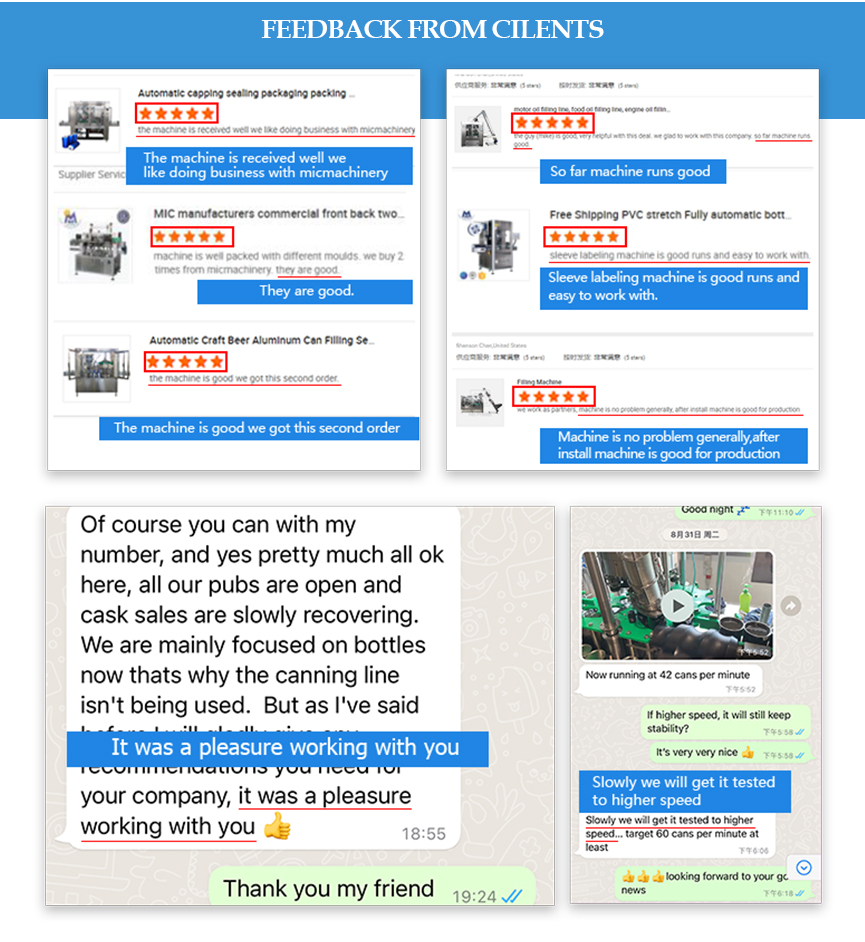

- Customer reviews: click on

One of the primary functions of the machine is Fill Level Monitoring with X-ray Inspection. By combining X-ray inspection with real-time monitoring capabilities, it ensures that liquid fill levels are maintained within specified tolerances, thus guaranteeing product quality and consistency. Whether it's beverages, pharmaceuticals, or chemicals, manufacturers rely on this machine to maintain optimal fill levels and avoid costly production errors.

Moreover, the machine serves as a comprehensive leakage-detection-machine, capable of identifying even the smallest leaks or imperfections in container seals. Through its advanced sensor systems and algorithms, it can detect leaks quickly and accurately, preventing product contamination and minimizing waste.

Another critical feature of the machine is its Automatic Vacuum Detection capability. Vacuum sealing is a common practice in many industries to preserve the freshness and integrity of liquid products. However, improperly sealed containers can lead to spoilage and product loss. With automatic vacuum detection, the machine can identify and rectify vacuum-related issues in real-time, ensuring that every container is properly sealed before leaving the production line.

In the food industry, particularly in the production of canned goods, the machine plays a vital role as a Canned Food Detection Machine. It utilizes advanced imaging technology to inspect cans for defects, ensuring that only high-quality products reach the market. From dented cans to misaligned seals, the machine can identify potential issues with precision, helping manufacturers maintain their reputation for quality and safety.

Beyond its individual capabilities, what sets the Liquid Level Detection Machine apart is its adaptability and scalability. It can be integrated seamlessly into existing production lines, providing manufacturers with a cost-effective solution for quality control. Whether it's a small-scale operation or a large-scale manufacturing facility, this machine can be customized to meet the specific needs of any industry.

In conclusion, the Liquid Level Detection Machine represents a cutting-edge solution for liquid monitoring and inspection. With its advanced X-ray technology, real-time monitoring capabilities, and automated detection systems, it sets a new standard for quality control in diverse industries. As businesses strive to meet ever-increasing demands for efficiency and precision, this machine stands ready to meet the challenges of tomorrow's manufacturing landscape.

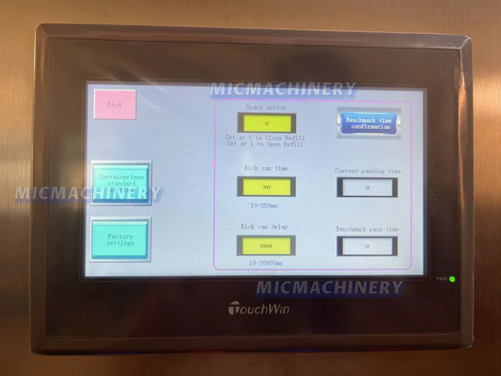

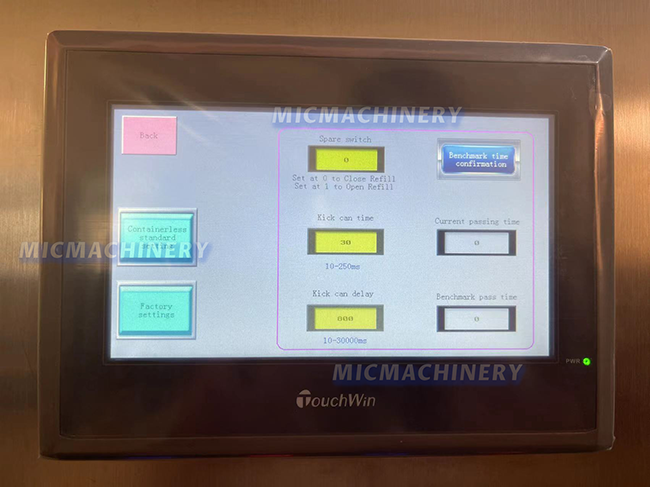

Control Panel

(1)Without warming-up, the detection can be conducted directly after starting up the product.

(2)Non-contact inspection, fast inspection speed, and high accuracy.

(3)The product can automatically fit to the different production line speed and realize dynamics detection.

Radiation, Do not close

The principle of that “the ray intensity changes with the charge level change of detected material after interaction between low-energy photon source and detected material” is utilized to control and inspect the filling liquid material capacity.

Measurement of elevation

Given its non—contact measure way, the product basically solve the problem that the conventional weighing method cannot measure the filling liquid material capacity on production line, and it’s widely applied in the automatic online control of filling liquid material production lines(both bottling and filling) of food, medicine, chemistry, weapon and ammunition etc

|

Technology Parameter

|

||||

|

Application

|

Beer, carbonated beverage, soft drink, cold coffee, herbal tea, fruit juice, and so on

|

|||

|

Suitable package

|

Aluminum cans, Tin cans, PET bottle and glass bottle

|

|||

|

Detect diameter

|

20MM-100MM

|

|||

|

Production speed

|

300-600 cans/minute

|

|||

|

Voltage

|

380V/50HZ/3Phase or 220V/50HZ/1Phase

|

|||

|

Weight

|

100KG

|

|||

|

Dimension

|

1300mm×800mm×500mm

|

|||

|

Main Configuration List

|

||||

|

PLC HMI

|

Siemens (Germany)

|

|||

|

Touch screen

|

Siemens (Germany)

|

|||

|

Reject solenoid valve

|

AirTAC (Taiwan, China)

|

|||

|

Reject air cylinder

|

AirTAC (Taiwan, China)

|

|||

|

Sensor

|

Omron (Japan)

|

|||

|

Switching power supply

|

Schneider (France)

|

|||

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment