Product Advantages

1. Versatility in Bottle Types:

One of the standout advantages is the adaptability to various bottle types. Whether you require a soda bottle filling machine for standard sizes, a pet bottle soda filling machine for lightweight and versatile PET bottles, or a specialized solution for glass bottle soda filling, our machines cater to your specific needs.

2. Precision Filling Technology:

Our machines boast precision filling technology, guaranteeing accurate and consistent fill levels for every bottle. This not only enhances the quality of the final product but also minimizes waste, contributing to a more cost-effective and sustainable production process.

3. Ease of Operation and Maintenance:

Designed with user-friendliness in mind, our soda bottling machines prioritize ease of operation and maintenance. Intuitive interfaces and straightforward maintenance procedures ensure that your production team can operate at peak efficiency without unnecessary downtime.

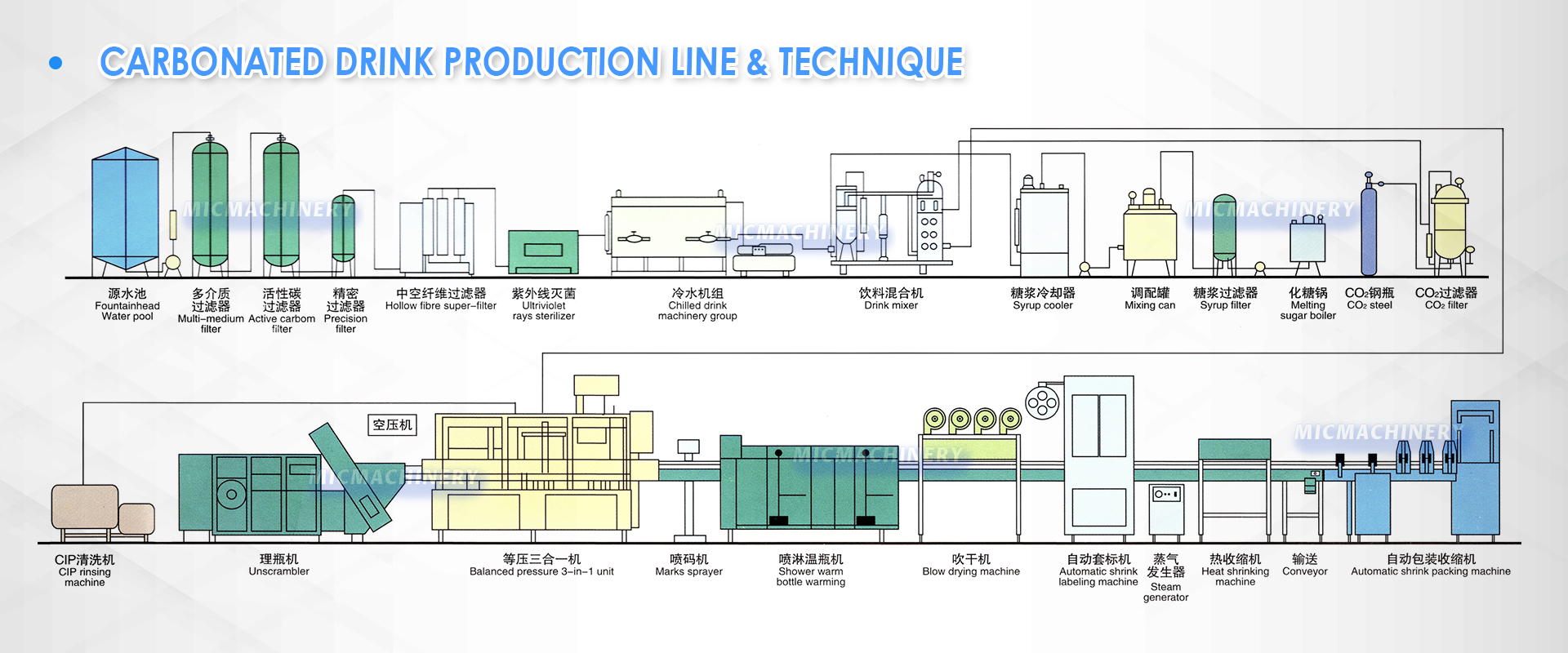

Machine Workflow

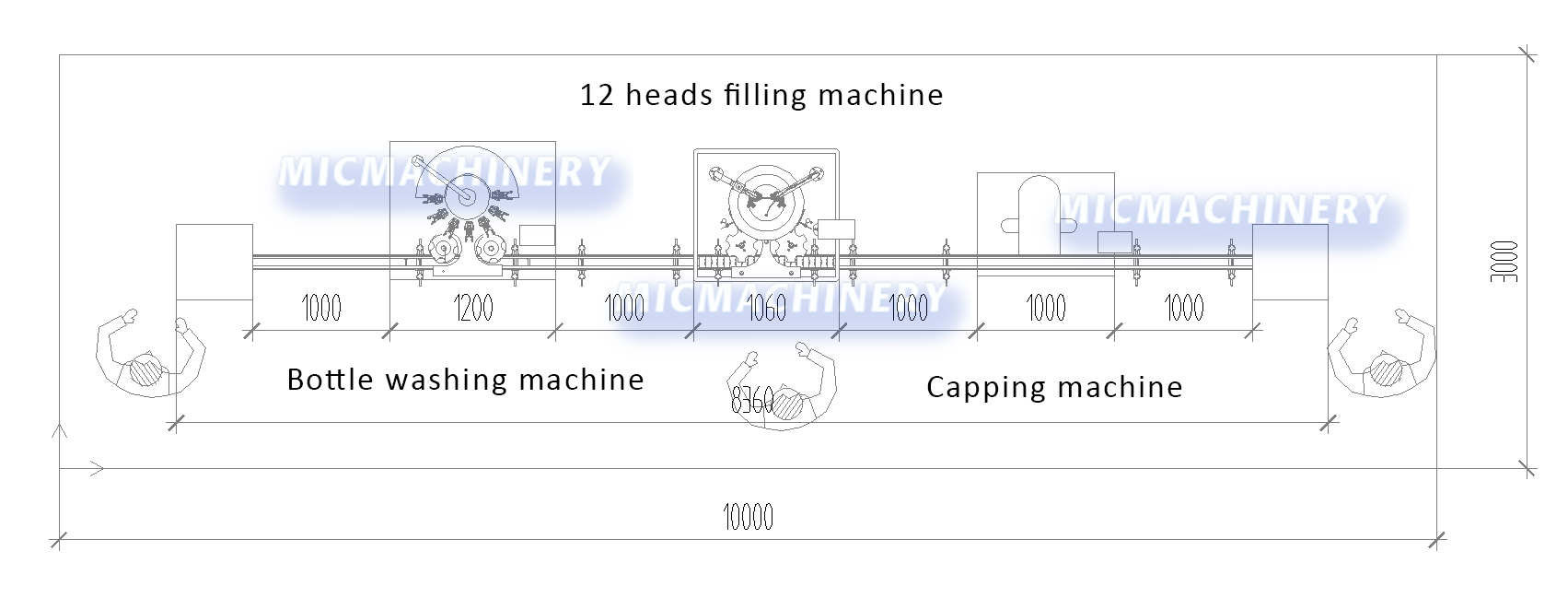

1. Bottle Feeding and Orientation:

The workflow begins with the systematic feeding and orientation of bottles. Our machines are equipped with advanced systems that ensure the correct alignment of bottles, setting the stage for a streamlined process.

2. Filling Station Excellence:

At the heart of our machines lies the filling station, where precision and efficiency converge. Whether it's a soda bottle filling machine, a pet bottle soda filling machine, or a glass bottle soda filling machine, this stage is designed to deliver accurate and consistent fills, maintaining the highest standards of beverage quality.

3. Sealing and Capping Perfection:

Post-filling, bottles seamlessly transition to the sealing and capping station. Here, our machines ensure a secure and hermetic seal, preserving the freshness and carbonation of the beverages within each bottle.

4. Quality Control Measures:

Integrated at every stage of the workflow are robust quality control measures. This ensures that only bottles meeting stringent standards proceed through the process, guaranteeing a final product that aligns with the excellence synonymous with Mic Machinery.

Technical Principle

1. Fill Level Sensors and Control Systems:

Advanced fill level sensors and control systems govern the precise filling of each bottle. These technologies eliminate variations in fill levels, ensuring a uniform product that meets the highest quality standards.

2. Automated Sealing Mechanisms:

The sealing and capping mechanisms are automated, utilizing state-of-the-art technology to secure each bottle with precision. This not only enhances efficiency but also minimizes the risk of errors in the sealing process.

3. Material Compatibility Considerations:

Our machines are designed with material compatibility in mind. Whether it's the robustness of a glass bottle or the lightweight flexibility of PET, the technical principles ensure seamless processing without compromising the integrity of the packaging material.

Speed: 800-1500BPH

Speed: 3000-5000BPH

Speed: 200-800BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 2000-3000BPH

Speed: 14000BPH

Understanding Soda Bottling Machine Prices: A Holistic View

At Mic Machinery, our pricing strategy reflects a commitment to transparency, adaptability, and unparalleled efficiency in soda bottling. Let's delve into the key dimensions that define our competitive prices:

1. Soda Bottling Machine Price:

Our soda bottling machine prices are meticulously structured to align with the diverse needs of the beverage industry. Whether you're a startup navigating budget constraints or an established player seeking efficiency upgrades, our pricing caters to a spectrum of requirements. Explore a range of options without compromising on the cutting-edge technology that defines our machines.

2. Soda Bottle Filling Machine Price:

Delve deeper into the specifics of our soda bottle filling machine prices, and you'll find a breakdown that emphasizes clarity and affordability. Our pricing strategy is crafted to empower businesses of all sizes, ensuring that the investment in efficient bottling technology is a strategic and accessible decision.

For those focused on pet bottle soda filling, our pricing structure underscores both competitiveness and adaptability. Recognizing the industry's evolving demands, our pet bottle soda filling machine prices are designed to offer value without compromise. Embrace efficiency without exceeding budget constraints.

Explore the realm of our glass bottle soda filling machine, where pricing is a delicate balance between quality and cost-effectiveness. Our commitment to providing competitive prices for this specialized machinery ensures that your investment aligns seamlessly with the unique demands of glass bottle production.

Factors Influencing Soda Bottling Machine Prices: A Deeper Dive

1. Machine Capacity and Throughput:

Our pricing structure considers the capacity and throughput of our soda bottling machines. Whether you require a compact solution for a smaller operation or seek high-volume production capabilities, our prices are tailored to reflect the performance specifications that precisely match your production scale.

Automation and technological features play a pivotal role in the efficiency of our machines. Our pricing acknowledges the level of automation and the advanced features that contribute to seamless and precision-driven bottling processes. From intuitive interfaces to cutting-edge control systems, our machines are priced to reflect the technological excellence embedded within.

3. Material Compatibility:

The choice of bottling material, whether PET or glass, is a critical consideration. Our pricing structure takes into account the nuances of material compatibility, ensuring that your selected machine is optimized for the specific characteristics of the chosen bottling material.

*Conclusion: Elevating Efficiency with Competitive Soda Bottling Machine Prices

In conclusion, at Mic Machinery, our dedication to providing competitive soda bottling machine prices stems from a commitment to transparency, adaptability, and customer satisfaction. Join us at Mic Machinery as we redefine efficiency in soda bottling, offering not just machines but strategic solutions that elevate your beverage production processes. Explore the possibilities with our advanced machinery, where technical precision and competitive pricing converge seamlessly.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment