Craft Beer Processing Equipment Manufacturer | Zhangjiagang Micmachinery

As the demand for premium artisanal beers continues to grow, breweries around the world are turning to professional craft beer processing equipment to meet quality standards and maintain consistent flavor. Zhangjiagang Micmachinery is a leading manufacturer offering complete craft brewing solutions tailored to small and medium-sized breweries. Our systems are designed to support the entire brewing cycle—from grain handling to final packaging—with precision, efficiency, and customizability.

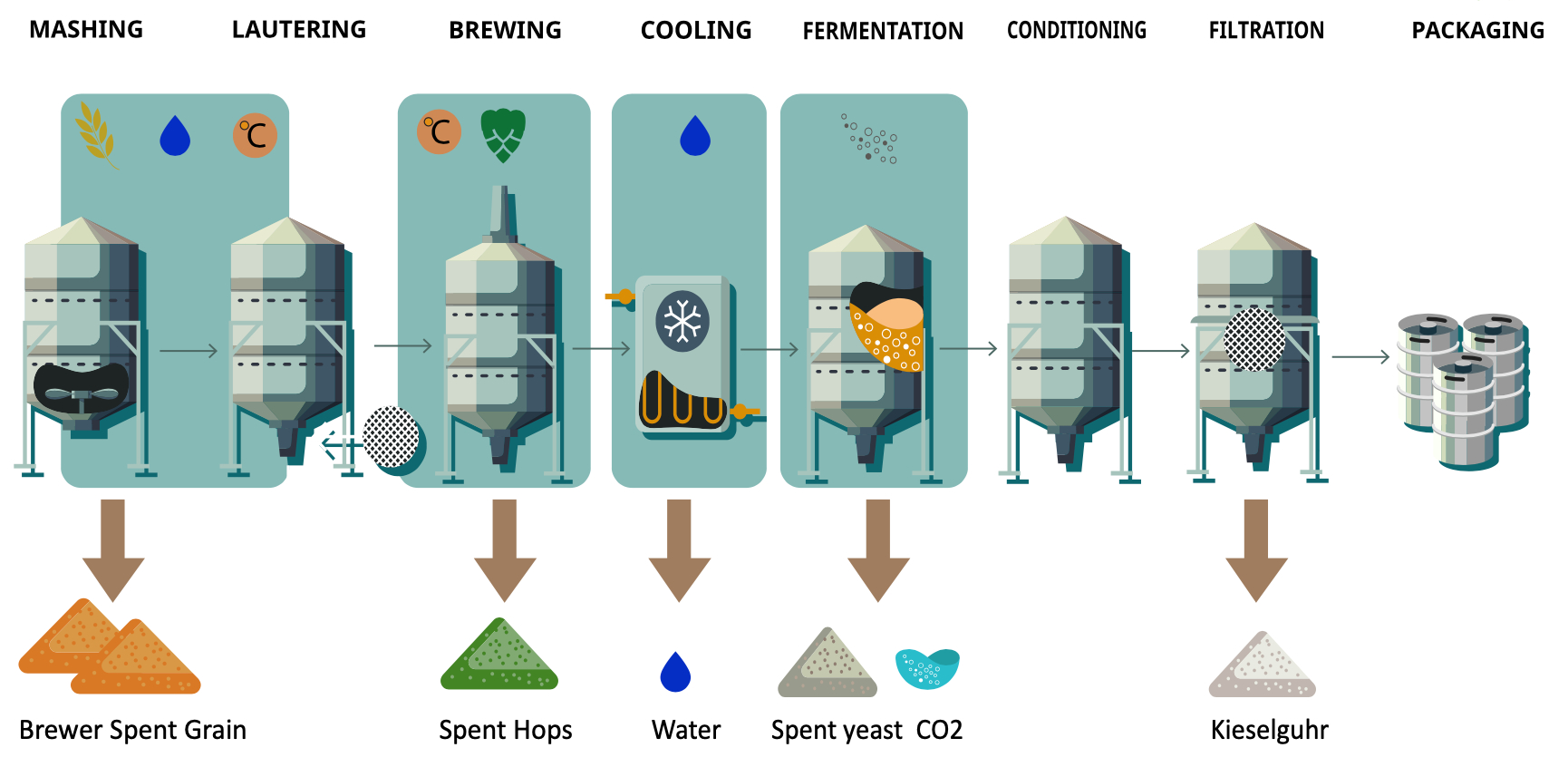

Brewing Process

Pre-treatment System – Malt Milling

A successful brewing process starts with malt preparation. Our pre-treatment system focuses on malt milling, which ensures that the grains are crushed to the optimal size for enzymatic conversion during mashing.

Modern craft beer brewing equipment commonly uses roller mills for dry milling. Depending on your brewery size, we offer two-, four-, five-, and six-roller configurations. Two-roller mills are often used in brewpubs, while four- to six-roller mills are more suitable for larger craft breweries.

Mashing System

Our mashing system is made entirely from food-grade stainless steel (SUS304), built with safety and hygiene in mind.

The mashing system includes non-slip platforms, safety railings, and perforated or patterned drainage floors. All piping and fittings are made from sanitary-grade stainless steel. Control can be managed through simple button operation or touch screens.

Depending on your capacity and production goals, the system can be configured in two-, three-, or four-vessel setups. Our volume range includes 50L, 100L, 200L, 300L, 500L, 800L, 1000L, 2500L, and 5000L. These flexible setups ensure our craft beer brewing equipment can scale with your growth.

Fermentation System

Fermentation tanks are at the heart of any brewery. Our fermenters and bright beer tanks are designed to provide stable, sanitary, and reliable fermentation.

Fermenters are made from SUS304 stainless steel and available in sizes from 50L to 10,000L. Each tank has a dish head top and 60-degree conical bottom for efficient yeast discharge. All tanks are 100% TIG welded, polished, and pressure tested (0.2MPa operating, 0.4MPa test).

Standard fermenters include four heavy-duty stainless steel legs with adjustable height and horizontal brackets. Larger tanks can be mounted on a fixed steel or concrete foundation.

This high-quality system forms the core of our craft beer brewing solutions, ensuring clean and consistent fermentation for every batch.

Filtration System

Once fermentation is complete, filtration plays a vital role in enhancing product clarity and extending shelf life.

Filtration in craft beer production is used for pre-filtration, yeast count control (to maintain haze), recovery of wort from heat coagulation residue, and reducing total suspended solids (TTS) to ensure a bottle-ready product.

The process must maintain low inlet and outlet temperatures to prevent flavor and aroma loss. This results in a longer shelf life for the beer.

We provide various filtration technologies, including diatomaceous earth filters, filter sheets, and centrifugal separators. These options can be selected based on product characteristics, production scale, and budget, providing breweries with comprehensive craft brewing solutions.

Packaging Process

At Zhangjiagang Micmachinery, our packaging lines are designed to integrate seamlessly with upstream brewing processes, providing clean, efficient, and scalable solutions.

Bottle (Can) Depalletizer

Forklifts place entire stacks of bottles onto the input platform. The stacks are conveyed to an unpacking station, where staff remove straps and wrapping. The unpacked stacks are moved to the bottom-lift platform.

A lifting mechanism raises the stacks, removes dividers, and transfers bottles to the conveyor. The bottles then move forward via the transport system.

This automated system improves handling speed and reduces labor intensity for craft beer operations.

Filling Machine

Our craft beer filling system includes rinser, filler, and capping/seaming units. These machines often feature automated CIP (clean-in-place), oxygen control, and high-speed filling technologies to preserve beer quality.

Rinsers eliminate contaminants. Filling machines maintain precise fill levels. Capping/seaming units ensure sealed, fresh packaging.

We offer systems suitable for:

• Glass bottles

• Aluminum cans

• Tinplate cans

• Steel kegs

• PET bottles

Production capacities range from 1,000 to 8,000 bottles per hour, ideal for small and mid-sized brewers. These partially automated solutions form a vital part of modern craft beer brewing equipment.

Continuous Tunnel Pasteurizer

The tunnel pasteurizer applies a three-stage process: hot water sterilization, warm water pre-cooling, and cold water final cooling. It is used for bottles and cans in atmospheric pasteurization processes.

Sterilization time and temperature are adjustable via automation. The machine is built entirely from stainless steel, offering stable performance and a polished appearance.

Available in four-, six-, and eight-temperature zone configurations, these units support both semi-automatic and fully automatic operations.

Conveyor System

We design conveyors based on product type, space constraints, and production needs. Conveyors include empty bottle conveyors, full bottle conveyors, case conveyors, and pallet conveyors.

Our team provides complete line installation, debugging, and training.

These components ensure uninterrupted flow throughout your craft beer processing equipment line.

Auxiliary Equipment

We provide auxiliary equipment tailored to your needs, including air dryers, inspection lights, manual packing stations, and systems for shrink wrapping, case packing, palletizing, liquid level detection, and inkjet coding.

Zhangjiagang Micmachinery supports your entire production with a full range of equipment, creating end-to-end craft beer brewing solutions for every scale.

Why Choose Zhangjiagang Micmachinery?

With over two decades of expertise, Zhangjiagang Micmachinery is a trusted provider of professional craft beer processing equipment. We serve global breweries seeking scalable, reliable, and hygienic brewing systems. Whether you’re a small startup or an established brand, our team can customize systems to match your brewing philosophy and production needs.

Craft beer brewing equipment must balance precision, tradition, and modern control. From malt milling to packaging, we deliver turnkey systems that enhance efficiency without compromising the artisanal integrity of your beer.

Get in Touch

Looking to expand your production with high-quality craft beer brewing solutions? Contact us today to get a custom quote and equipment recommendation.