Mechanical Principle

1. Synchronized Conveyor Systems: Our Mechanical Principle boasts:

• Precision Synchronization: State-of-the-art conveyor technology ensures a seamless flow of PET bottles, optimizing the speed and precision of the entire packaging process.

• High-Speed Rotation Mechanism: An innovative mechanism that enhances bottle movement, contributing to the remarkable speed of our bottling line.

2. Bottle Orientation Control: Elevating precision with:

• Advanced Bottle Orientation Devices: Ensuring precise bottle positioning for uniform filling and capping.

• Dynamic Bottle Handling: Adaptable to variations in bottle size and shape, maintaining stable and controlled bottle flow.

3. Hygienic Design Principles: Prioritizing cleanliness with:

• Stainless-Steel Components: High-quality stainless-steel components adhere to hygienic design principles, ensuring product purity.

• Easy-to-Clean Structures: Streamlining maintenance for minimal downtime.

4. Energy-Efficient Drive Systems: Ensuring sustainability with:

• Energy-Efficient Motors: Advanced drives contribute to sustainable and cost-effective operations.

• Variable Speed Controls: Smart controls optimize energy consumption based on production demand.

Machine Function

1. Consistent Fill Levels: Mic Machinery's high-speed pet bottling line functions with unparalleled precision, ensuring:

• Uniform Fill Levels: Our equipment guarantees a consistent fill for every PET bottle, preserving the quality and integrity of your beverage.

• Automated Filling Mechanism: The system incorporates advanced automation, minimizing variations, and optimizing the overall packaging process.

2. Adaptability for Diverse Products: Our high-speed pet bottling line functions with versatility, accommodating a myriad of liquid products:

• Customizable Filling Parameters: Tailor the machine settings to match the specific characteristics of various beverages, ensuring precise fills tailored to unique formulations.

• Flexibility in Bottle Sizes: With adaptability to various PET bottle sizes, our equipment provides manufacturers the freedom to package their products in diverse containers.

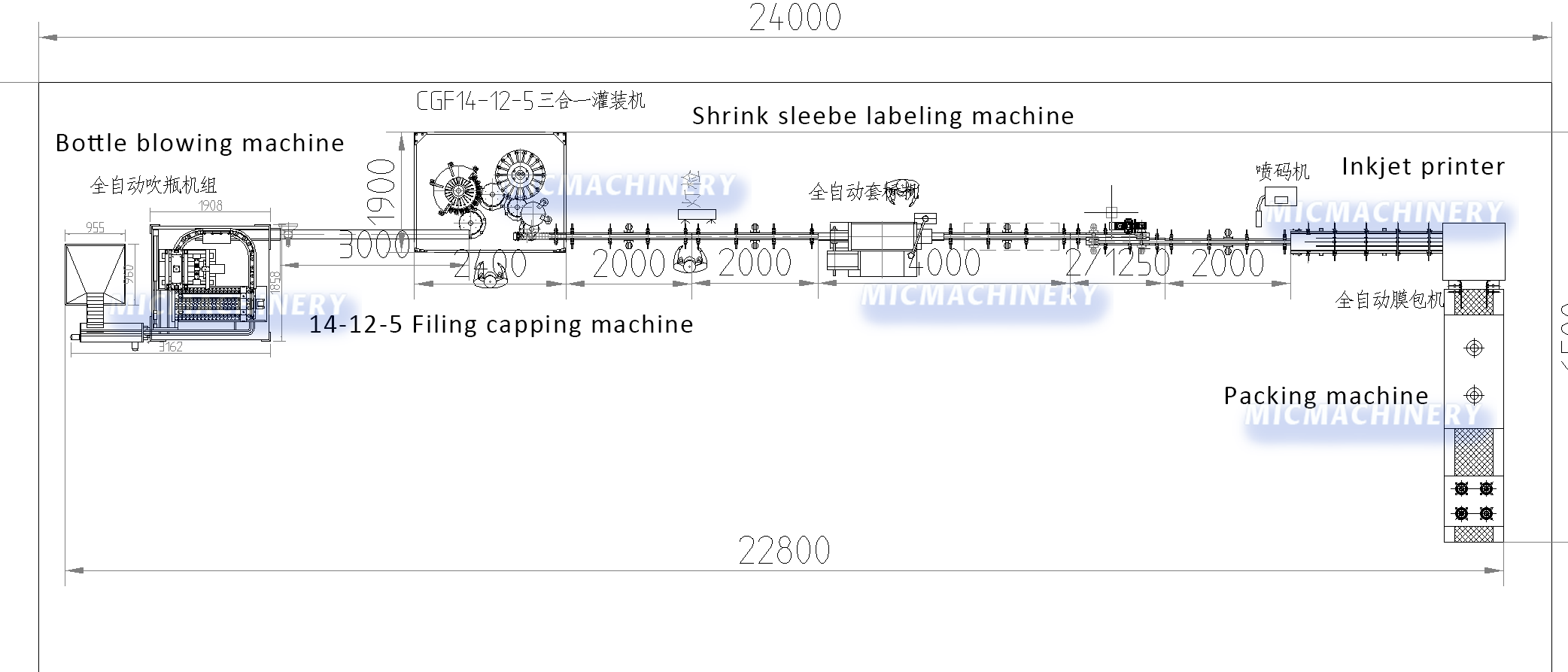

Machine Workflow

1. Automated Bottle Loading: Experience an efficient workflow with:

Integrated Loading System: Our high-speed pet bottling line incorporates automated bottle loading, minimizing downtime and maximizing production efficiency.

2. Precision Filling and Capping: The machine workflow includes:

Simultaneous Filling and Capping: Achieve a seamless transition from filling to capping, reducing the time between these crucial production steps.

3. Quality Control Stations: Elevate product quality assurance with:

In-Line Quality Control: Integration of quality control stations ensures each bottle meets stringent quality standards before advancing to the next stage.

4. User-Friendly Interface: Navigate the workflow with ease:

Intuitive Controls: The high-speed pet bottling line features a user-friendly interface, empowering operators to monitor and control the workflow effortlessly.

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

High-Speed Bottling Line: Precision in Motion:

Synchronized Conveyor Systems:

At the core of Mic Machinery's high-speed pet bottling line is an innovative approach to speed:

• Precision Synchronization: Our system employs state-of-the-art conveyor technology with precise synchronization, ensuring a seamless and continuous flow of PET bottles throughout the entire bottling process.

• High-Speed Rotation Mechanism: The bottling line incorporates a high-speed rotation mechanism, optimizing bottle movement and significantly enhancing the overall speed and precision of the packaging operation.

Automatic Bottle Water Machine: Seamless Operation, Every Drop Matters:

Consistent Filling Mechanism:

In the realm of the automatic bottle water machine, Mic Machinery ensures:

• Uniform Fill Levels: Our equipment guarantees a consistent fill for every PET bottle, preserving the quality and integrity of the packaged water.

• Automated Precision: Advanced automation minimizes variations, optimizing the overall packaging process for efficiency.

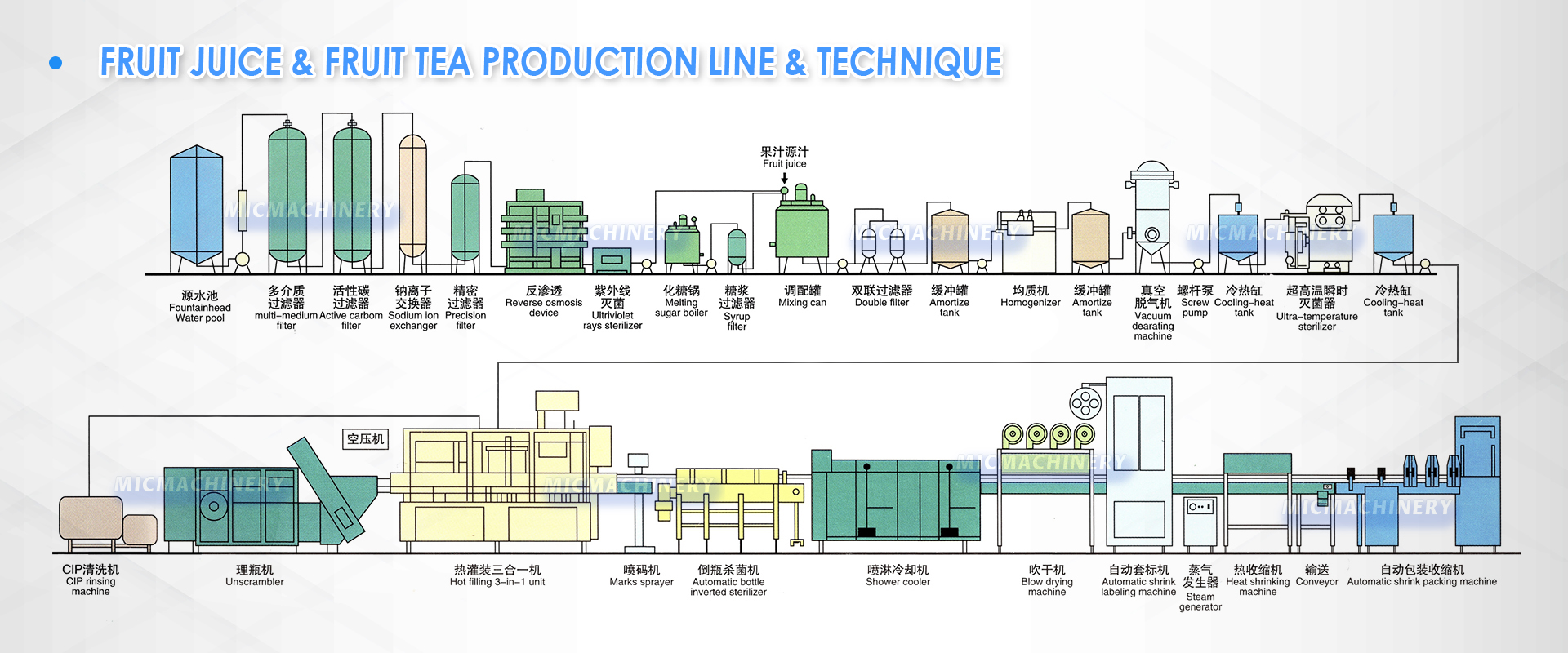

Automatic Liquid Filling Line: Streamlined Excellence in Every Container:

Customizable Parameters:

The automatic liquid filling line excels with:

• Tailored Filling Parameters: Manufacturers can customize machine settings to match the specific characteristics of various beverages, ensuring precise fills tailored to unique formulations.

• Flexibility in Container Sizes: With adaptability to various bottle sizes, our equipment provides manufacturers the freedom to package their products in diverse containers.

In conclusion, Mic Machinery invites beverage producers to explore a new era of efficiency and precision with our high-speed pet bottling line solutions. Discover the technical intricacies that define our high-speed bottling line, automatic bottle water machine, and automatic liquid filling line. Whether you're a startup or an established brand, Mic Machinery is your trusted partner in crafting packaging solutions that meet the highest standards of excellence. Because every PET bottle deserves the precision and efficiency Mic Machinery brings to your production line.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

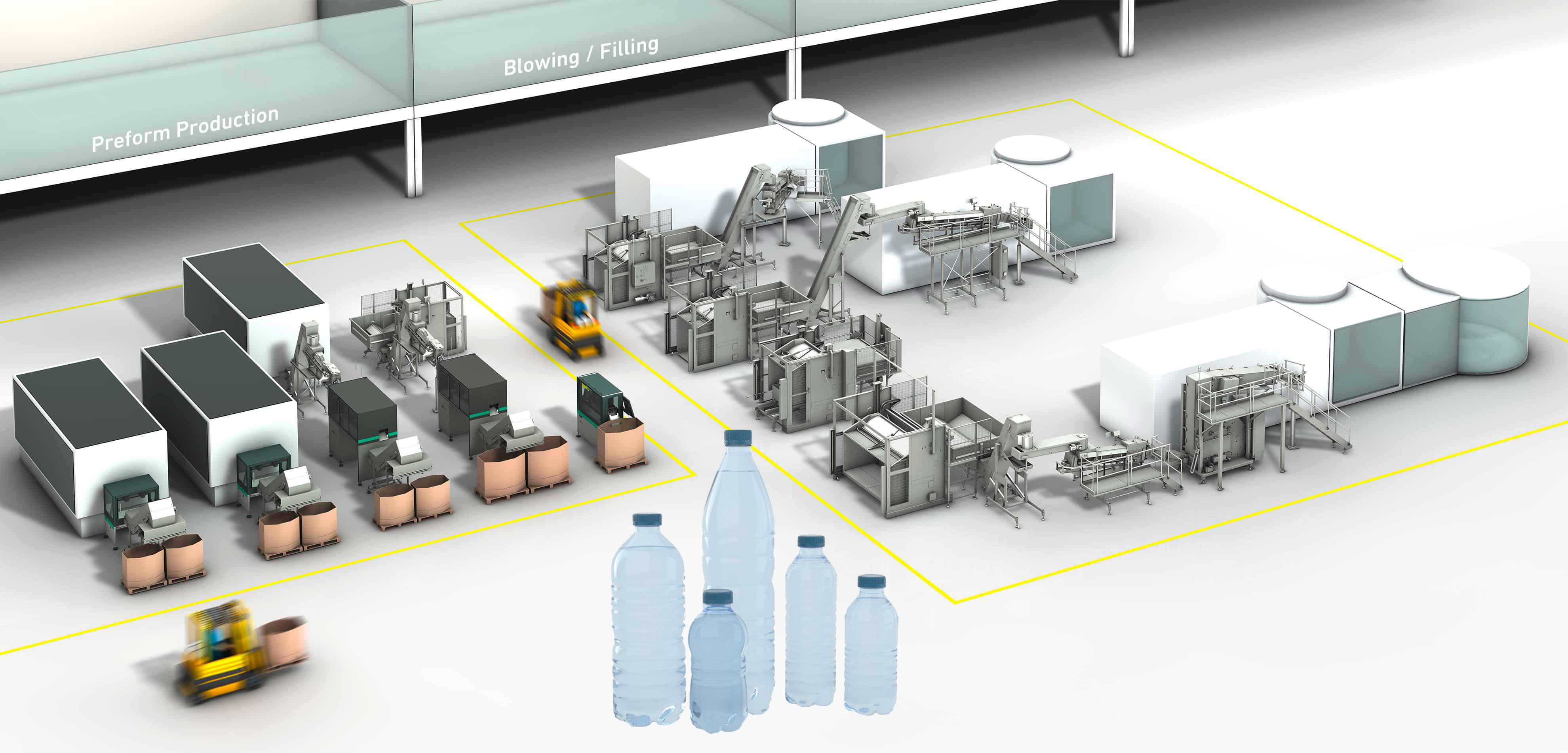

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment