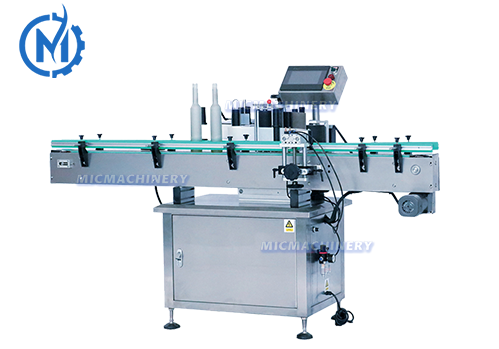

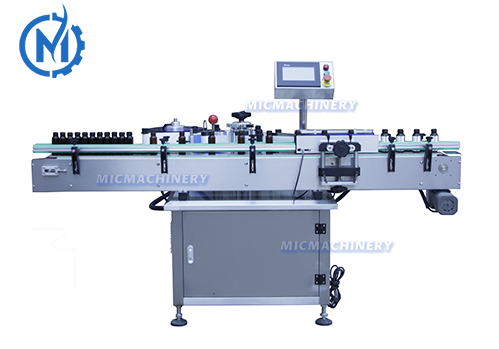

Round Bottle Labeling Machine Manufacturer-Automatic & Precise Labeling for Cylindrical Bottles

Jiangsu Mic Machinery offers high-performance Round Bottle Labeling Machines designed for quick, accurate, and efficient labeling of cylindrical containers. Whether you’re labeling plastic, glass, or metal bottles, our machines ensure clean application and perfect alignment at high speeds.

Used across food, beverage, pharmaceutical, and cosmetic industries, these labelers are engineered for both front-and-back or full-wrap-around label application.

What is a Round Bottle Labeling Machine?

A Round Bottle Labeling Machine is an automated system that applies adhesive labels onto cylindrical bottles or jars. Bottles move along a conveyor and pass through a labeling station, where labels are precisely dispensed and smoothed with rollers or brushes for wrinkle-free application.

Mic Machinery's labeling equipment handles a wide variety of bottle diameters and label types with minimal adjustment, making it ideal for short runs or frequent product changeovers.

Round bottle labeling machine parameter comparison table

|

Parameter |

Location Labeling Machine |

Location Labeling Machines |

Single-sided Adhesive Labeling Machines |

Vertical Round Bottle Sticker Labeling Machines |

Round Bottle Labeling Machines |

|

Model |

Location Labeling Machine |

Location Labeling Machines |

Single-sided Adhesive Labeling Machines |

Vertical Round Bottle Sticker Labeling Machines |

MIC-RT60 |

|

Capacity |

60-100 PCS/min |

30-40 BBL/min |

80-220 vials/min |

50-120 vials/min |

30-150 pcs/min |

|

Power |

1800W |

1.0KW |

2500W |

1.0KW |

800W |

|

Labeling Speed |

60-100 PCS/min |

30-40 BBL/min |

80-220 vials/min |

50-120 vials/min |

30-150 pcs/min |

|

Dimensions (mm) |

- |

2000×800×1300 |

2800×1450×1500 |

2000×800×1300 |

1800×800×1300 |

|

Voltage |

L/N/PE 220V 50Hz |

AC220V 50/60HZ |

AC220V 50/60HZ |

AC220V 50/60HZ |

AC220V 50/60HZ |

|

Label Size |

- |

Height: 10-150mm, Length: 15-300mm |

Height: 10-180mm, Length: 15-200mm |

Height: 10-150mm, Length: 15-300mm |

Width: 15-300mm, Length: 15-300mm |

|

Weight (kg) |

- |

250KG |

310KG |

200KG |

200KG |

|

Other Specifications |

Conveyor speed: 3~25m/min, Labeling accuracy: ±1mm |

Bucket diameter: Φ60-160mm, Air source pressure: 0.4~0.6Mpa |

Object size: Length 30-300mm, Width 20-140mm, Height 55-400mm |

Bottle diameter: 25-120mm, Height: 20-300mm |

Driving Mode: Servo motor, Operating direction: Left or Right |

Why Choose Our Round Bottle Labeling Machine?

-

Quick Changeover: Adjust bottle or label size in minutes

-

Operator Friendly: Designed for minimal training and fast setup

-

Stable Label Application: Prevents skewing or wrinkling

-

OEM & Custom Design Available: Match your exact production line needs

if you're in the business of packaging products in round bottles, you know that labeling those bottles can be a time-consuming and tedious process. That's where round bottle labeling machines come in. These machines automate the labeling process, saving you time and increasing your efficiency.

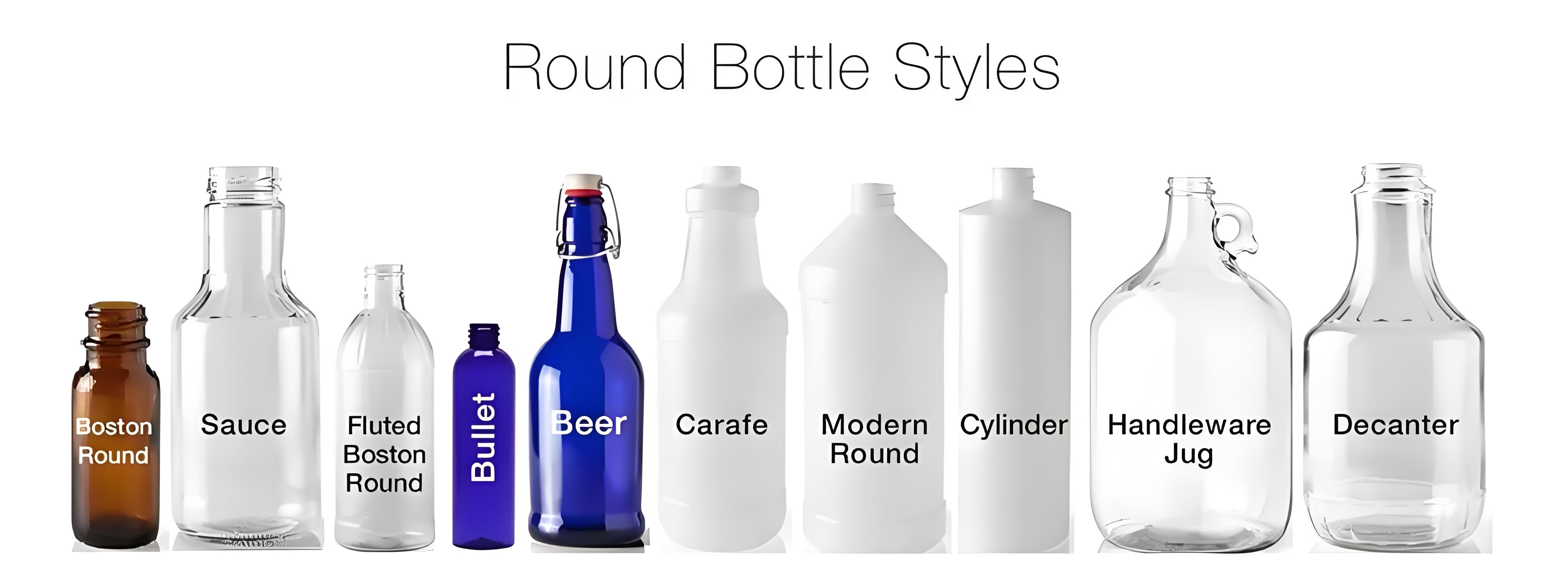

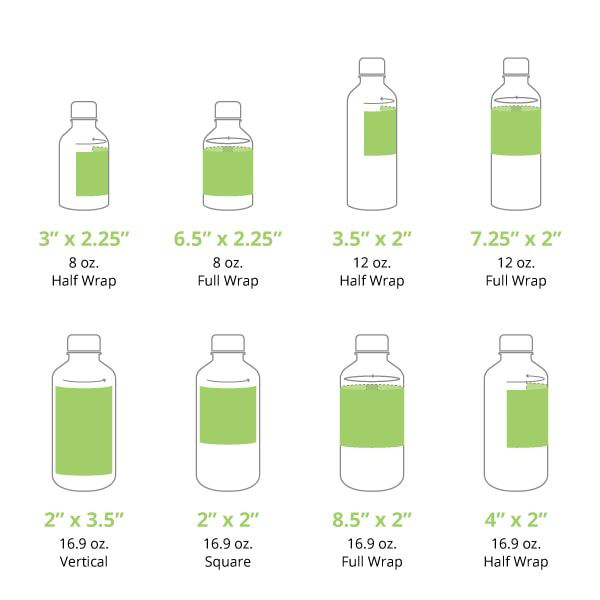

In this article, we'll discuss three types of round bottle labeling machines: location labeling machines, single-sided adhesive labeling machines, and vertical round bottle sticker labeling machines. We'll cover the benefits of each type and give you some tips on how to choose the right machine for your business.

Location Labeling Machines

Location labeling machines are designed to apply labels to a specific location on a round bottle. These machines can be set up to apply labels to the top, bottom, or sides of the bottle. They're perfect for businesses that need to apply labels to a specific area of the bottle for branding or regulatory compliance.

One of the benefits of location labeling machines is their accuracy. They can apply labels with precision, ensuring that each bottle is labeled correctly. They're also versatile, with the ability to label bottles of different sizes and shapes.

Single-sided Adhesive Labeling Machines

Single-sided adhesive labeling machines apply labels to one side of a round bottle. They're ideal for businesses that need to apply a label to a specific area of the bottle, such as the front or back. These machines are also great for applying barcodes, QR codes, or other identification codes to the bottle.

One of the benefits of single-sided adhesive labeling machines is their speed. They can label bottles quickly, making them ideal for high-volume production. They're also easy to operate and maintain, with minimal downtime.

Vertical Round Bottle Sticker Labeling Machines

Vertical round bottle sticker labeling machines apply labels to the entire circumference of a round bottle. These machines are designed to handle a wide range of bottle sizes and shapes. They're ideal for businesses that need to apply labels to a large number of bottles quickly and efficiently.

One of the benefits of vertical round bottle sticker labeling machines is their accuracy. They can apply labels with precision, ensuring that each bottle is labeled correctly. They're also versatile, with the ability to label bottles of different sizes and shapes.

Choosing the Right Round Bottle Labeling Machine

When choosing a round bottle labeling machine, it's important to consider your business's specific needs. Think about the types of bottles you'll be labeling, the volume of production, and the level of accuracy required. You should also consider the size of the machine, as well as the ease of use and maintenance.

In conclusion, round bottle labeling machines can be a valuable investment for businesses that package products in round bottles. Whether you need a location labeling machine, a single-sided adhesive labeling machine, or a vertical round bottle sticker labeling machine, there's a machine out there that can meet your needs. Consider your specific requirements, and choose a machine that can increase your efficiency and productivity.