Machine Usage

1. Effortless Operation for Bottling Excellence:

The usage of water filling lines is characterized by an effortless operation, emphasizing user-friendly interfaces. Operators, regardless of experience, can navigate the intuitive controls seamlessly. This user-centric design enhances overall productivity, making these lines ideal for businesses seeking efficiency in their bottling processes.

2. Adaptability for Diverse Bottling Needs:

Water filling lines exhibit adaptability to diverse bottling needs. Whether you're a large-scale operation or a smaller business, the flexibility of these systems caters to varying production volumes. This adaptability ensures that water bottling, regardless of scale, remains efficient and cost-effective.

3. Streamlined Small Water Filling Machine Options:

For businesses with specific production requirements, the availability of streamlined options like "small water filling machine price" addresses the need for tailored solutions. These compact machines offer efficiency on a smaller scale, making them a strategic choice for businesses navigating space constraints or focusing on niche markets.

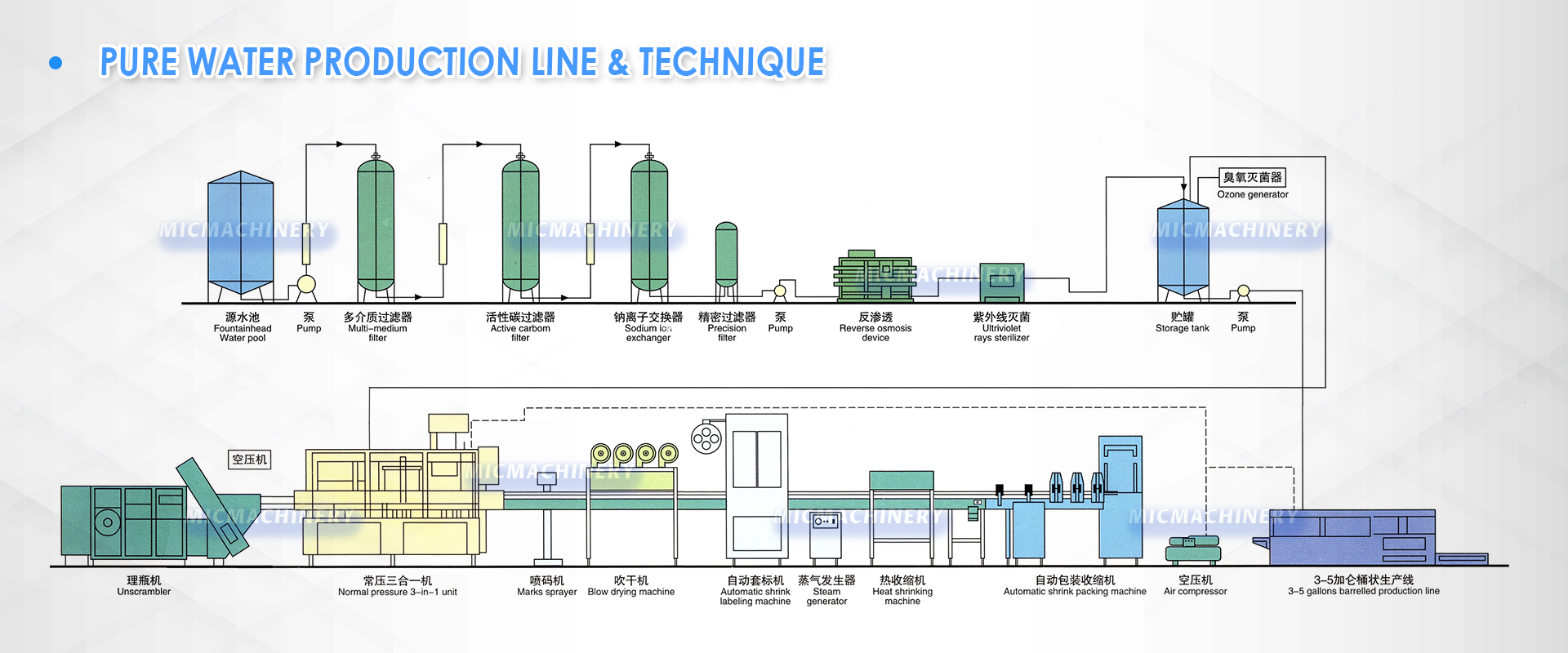

Technical Principle

1. Gravity and Pressure Precision in Filling:

At the heart of the technical principle lies the precision of gravity and pressure-based filling mechanisms. These systems ensure a controlled liquid flow, guaranteeing uniform filling levels in each bottle. The integration of gravity and pressure principles not only enhances accuracy but also contributes to the overall speed and efficiency of the filling process.

2. Automated Quality Assurance Mechanisms:

Technical excellence extends to automated quality assurance mechanisms. Sensors and advanced systems monitor every phase of the production process, from bottle conveyance to filling. This automation ensures that each bottle adheres to stringent quality standards, minimizing variations and upholding the highest product integrity.

3. Compact Design for Small Water Filling Machines:

The technical design of small water filling machines is tailored for efficiency within a smaller footprint. These machines utilize innovative engineering to maintain precision and accuracy, even with reduced dimensions. This compact design not only addresses spatial constraints but also aligns with the resource-efficient needs of smaller operations.

Machine Parameter

1. Production Capacity Variability:

A critical parameter of water filling lines is their production capacity variability. These lines are finely parameterized to accommodate the demands of various businesses. Whether seeking high-volume production or opting for a more moderate scale, the machine parameters can be adjusted to align with specific production needs.

2. Adjustable Filling Speeds:

The flexibility of these lines extends to adjustable filling speeds. Businesses can customize the speed of the filling process based on bottle sizes, product variations, and overall production goals. This parameter allows for optimization, ensuring efficient operations without compromising quality.

3. Cost-Efficient Small Water Filling Machine Price:

The parameter of cost-efficiency is evident in the "small water filling machine price." Designed to provide effective solutions without burdening budgets, these machines offer a strategic balance between affordability and advanced technology. The parameter of cost is finely tuned to make quality bottling accessible to a broad spectrum of businesses.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Water Filling Line:

At the core of our offerings lies our advanced water filling line, meticulously engineered to cater to the diverse needs of the water bottling industry. From compact models suitable for small-scale operations to larger, high-capacity systems, our filling lines are designed to deliver efficiency, accuracy, and reliability throughout the water bottling process. Each element, from precise filling to secure sealing, is intricately integrated to ensure a streamlined production flow.

Water Bottle Machine Price:

In our commitment to transparency and accessibility, we present competitive water bottle machine prices that make advanced technology within reach for businesses of all sizes. We understand the importance of cost-effectiveness in today's market, and our pricing structure reflects our dedication to providing affordable solutions without compromising on quality.

Small Water Filling Machine Price:

For businesses with limited production needs, our range includes compact and efficient models with a focus on cost-effectiveness. Explore our small water filling machine prices that deliver the same precision and reliability as larger counterparts, providing an ideal solution for small-scale water bottling operations.

Key Features of Mic Machinery's Water Filling Line:

1. Precision Filling:

Our filling line ensures accurate volume control, minimizing wastage and maximizing production efficiency.

2. Secure Sealing:

Every bottle filled undergoes secure sealing, maintaining the integrity of your product and ensuring customer satisfaction.

3. Adaptability:

From small-scale to high-capacity operations, our water filling line is designed to be adaptable to various production needs.

4. User-Friendly Interface:

Intuitive controls and user-friendly interfaces make our machines easy to operate, reducing the need for extensive training.

Why Choose Mic Machinery:

1. Innovation and Technology:

We stay ahead of industry trends, incorporating the latest technological advancements into our water filling line for optimal performance.

2. Affordable Solutions:

Our commitment to affordability ensures that businesses of all sizes can benefit from advanced water bottling technology without breaking the bank.

3. Reliability:

Count on Mic Machinery for reliable solutions that prioritize consistency, precision, and efficiency throughout the water bottling process.

4. Customized Support:

Our team is dedicated to providing personalized support, helping you choose the right water filling line tailored to your specific business requirements.

Embark on a journey of efficiency and cost-effectiveness with Mic Machinery's water filling line solutions. We invite you to explore our range, discover unparalleled quality, and elevate your water bottling operations to new heights.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment