Labeling Machine Manufacturer

Zhangjiagang Mic Machinery offers advanced labeling machines designed for accurate, efficient application of labels on a variety of containers, including round, square, flat, and irregular shapes. Ideal for food, beverage, cosmetics, chemical, and pharmaceutical industries, our systems deliver consistent, bubble-free, and visually impressive labeling results to enhance product appeal and brand identity.

A Comprehensive Guide to Labeling Machines for Your Business Needs

Labeling machines are essential pieces of equipment for businesses that require accurate and efficient labeling of their products. They come in various types, sizes, and configurations to meet the specific labeling needs of different products. In this article, we'll discuss the different types of labeling machines available in the market, their features, benefits, and how they can help businesses increase their production efficiency.

Round bottle labeling machine parameter comparison table

|

Parameter |

Location Labeling Machine |

Location Labeling Machines |

Single-sided Adhesive Labeling Machines |

Vertical Round Bottle Sticker Labeling Machines |

Round Bottle Labeling Machines |

|

Model |

Location Labeling Machine |

Location Labeling Machines |

Single-sided Adhesive Labeling Machines |

Vertical Round Bottle Sticker Labeling Machines |

MIC-RT60 |

|

Capacity |

60-100 PCS/min |

30-40 BBL/min |

80-220 vials/min |

50-120 vials/min |

30-150 pcs/min |

|

Power |

1800W |

1.0KW |

2500W |

1.0KW |

800W |

|

Labeling Speed |

60-100 PCS/min |

30-40 BBL/min |

80-220 vials/min |

50-120 vials/min |

30-150 pcs/min |

|

Dimensions (mm) |

- |

2000×800×1300 |

2800×1450×1500 |

2000×800×1300 |

1800×800×1300 |

|

Voltage |

L/N/PE 220V 50Hz |

AC220V 50/60HZ |

AC220V 50/60HZ |

AC220V 50/60HZ |

AC220V 50/60HZ |

|

Label Size |

- |

Height: 10-150mm, Length: 15-300mm |

Height: 10-180mm, Length: 15-200mm |

Height: 10-150mm, Length: 15-300mm |

Width: 15-300mm, Length: 15-300mm |

|

Weight (kg) |

- |

250KG |

310KG |

200KG |

200KG |

|

Other Specifications |

Conveyor speed: 3~25m/min, Labeling accuracy: ±1mm |

Bucket diameter: Φ60-160mm, Air source pressure: 0.4~0.6Mpa |

Object size: Length 30-300mm, Width 20-140mm, Height 55-400mm |

Bottle diameter: 25-120mm, Height: 20-300mm |

Driving Mode: Servo motor, Operating direction: Left or Right |

Shrink Sleeve Labeling Machines parameter comparison table

|

Parameter |

Automatic Sleeve Labeling Machine |

Shrink Labeling Machine |

Sleeve Labeling Machine |

Sleeve Shrink Labeling Machine |

Bottle Shrink Sleeve Machine |

Automatic Shrink Sleeve Labeling Machine |

Shrink Sleeve Labeling Machine |

|

Power |

1.5KW |

3KW |

- |

8.0KW |

0.75KW |

0.75KW |

3.0KW |

|

Labeling Speed |

Maximum 50 bottles/min |

9000 b/h |

150 bottles/min |

600 bottles/min |

0-35m/min |

0-35m/min |

150 bottles/min |

|

Dimensions (mm) |

2000×850×2000 |

- |

2000×850×2000 |

2800×1200×2200 |

L2500×W600×H450 |

L1800×W600×H450 |

L2100×W850×H2000 |

|

Voltage |

3380/220VAC |

AC220V, 50/60HZ |

3,380 1220VAC |

3,380 1220VAC |

3,220VAC |

1,220VAC |

∮3, 380/220 VAC |

|

Label Size |

Height: 30-150mm, Thickness: 0.03-0.13mm |

Length: 100mm, Thickness: 0.045mm |

Height: 30-150mm, Thickness: 0.03-0.13mm |

Length: 30-250mm, Thickness: 0.03-0.13mm |

- |

- |

Length: 30-250mm, Thickness: 0.03-0.13mm |

|

Weight (kg) |

- |

- |

- |

- |

230kg |

230kg |

- |

|

Other Specifications |

Applicable bottle diameter: 50-96mm, Paper tube: 5"-10" |

Material: PVC, PET, OPS |

Applicable bottle diameter: 30-55mm |

Applicable bottle diameter: 48-96mm |

Steam Consumption: 10-20Kg/h |

Steam Consumption: 20-30Kg/h |

Applicable container diameter: φ28-φ120mm |

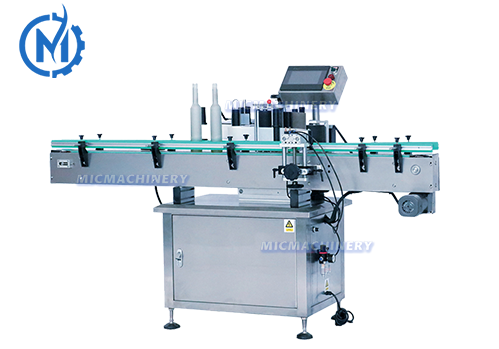

Round Bottle Labeling Machine

Round bottle labeling machines are designed specifically for labeling round bottles such as vials, ampoules, and cylindrical containers. They come with advanced features such as automatic bottle positioning, label detection, and label applicator to ensure accurate and consistent labeling. They can also be used to apply multiple labels on the same bottle, making them ideal for businesses that require multi-language labeling or promotional labeling.

Double Side Labeling Machine

Double side labeling machines are designed to label both sides of a product simultaneously. They can be used for labeling products such as flat containers, boxes, and bags. They come with advanced features such as automatic product alignment, label detection, and label applicator to ensure accurate and consistent labeling. They are ideal for businesses that require labeling on both sides of their products to enhance visibility or comply with regulatory requirements.

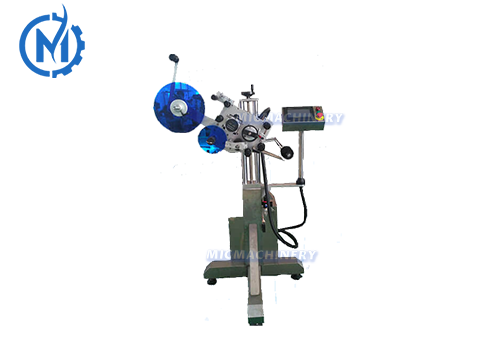

Flat Surface Labeling Machine

Flat surface labeling machines are designed specifically for labeling flat surfaces such as cartons, boxes, and bags. They come with advanced features such as automatic product alignment, label detection, and label applicator to ensure accurate and consistent labeling. They are ideal for businesses that require high-speed labeling of flat surface products, such as in the food and beverage industry.

Benefits of Using a Labeling Machine

There are several benefits of using a labeling machine, including:

Increased Production Efficiency: Labeling machines can label hundreds or even thousands of products per hour, which helps to increase production efficiency.

Consistency: Labeling machines can label products with a consistent label placement, which helps to maintain the quality of the products and reduce wastage.

Cost-Effective: Labeling machines are cost-effective compared to manual labeling, which makes them ideal for businesses that require high-speed labeling and accurate label placement.

Conclusion

Labeling machines are essential pieces of equipment for businesses that require accurate and efficient labeling of their products. With different types of machines available in the market, businesses can choose the machine that best suits their labeling needs. Whether you're labeling round bottles, double-sided products, flat surfaces, or oral bottles, a labeling machine can help you increase your production efficiency and maintain the quality of your labeled products.