Machine Application

1. Beer Bottling Machine for Sale:

Tailored for craft breweries and small-scale beer producers, our machine ensures precise and controlled filling, preserving the freshness and carbonation of each bottle.

2. Carbonated Beverage Bottling Equipment:

Versatility is at the core of our machine's design, making it equally adept at handling various carbonated beverages. From sodas to sparkling water, our small-scale solution adapts to the nuanced requirements of carbonated drink production.

Machine Function

1. Accurate Filling Mechanism:

The machine incorporates a precision filling mechanism, ensuring consistent fill levels with each cycle. This accuracy is crucial for maintaining product integrity and meeting the high standards expected by consumers.

2. Efficient Capping System:

Beyond filling, our machine integrates an efficient capping system to securely seal each bottle. This feature not only prevents leaks but also contributes to the preservation of the beverage's carbonation levels.

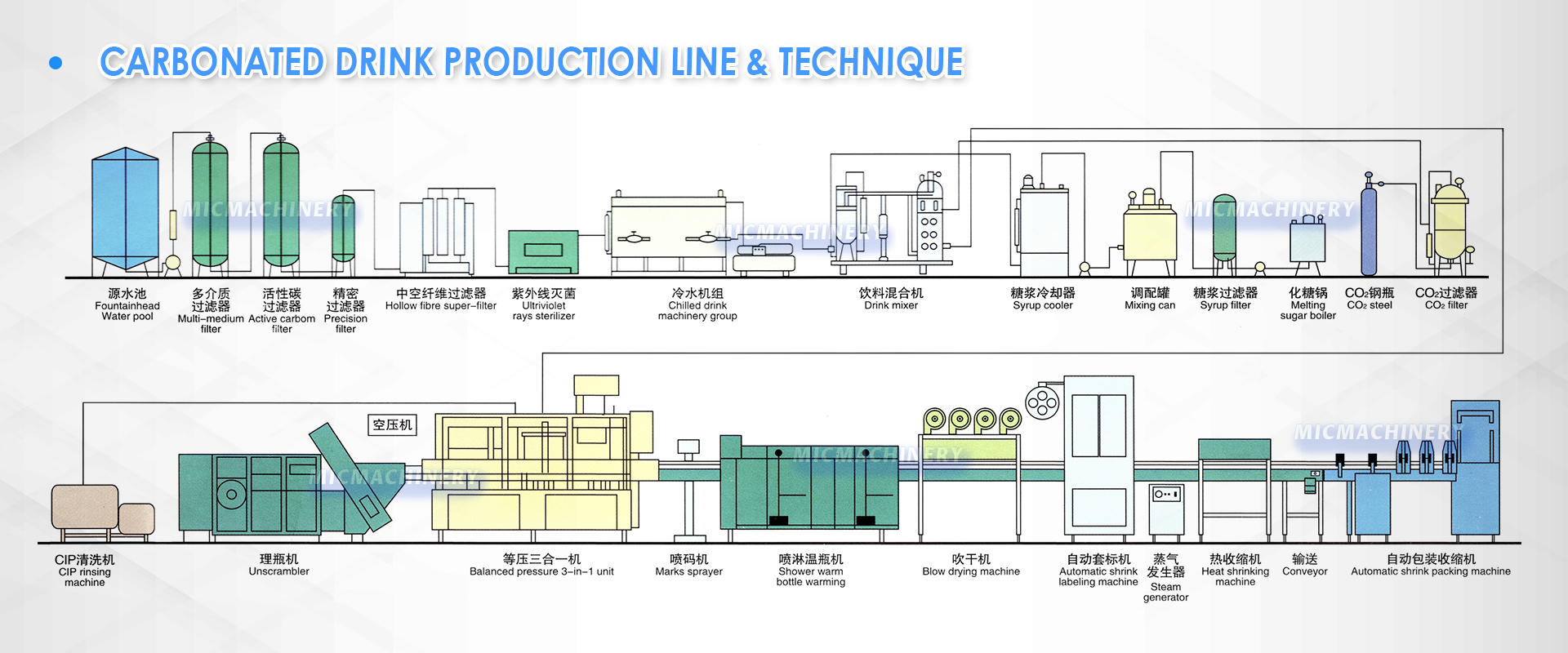

Mechanical Principle

1. CO2 Infusion Technology:

Operating on the principle of CO2 infusion, our machine carefully controls the carbonation process, ensuring that each bottle receives the perfect amount of effervescence. This technology enhances the overall drinking experience.

2. Automated Valve Control:

The machine's automated valve control optimizes the filling process. By minimizing human intervention, it streamlines the workflow and reduces the likelihood of errors, contributing to the efficiency of small-scale production.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1000-1500CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 480CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 1800CPH

Speed: 800-1500BPH

Speed: 2000-3000BPH

Speed: 200-800BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 3000-5000BPH

Speed: 14000BPH

Small Carbonated Drink Filling Machine Overview:

At Mic Machinery, we understand the unique challenges faced by small-scale producers. Our small carbonated drink filling machine is engineered to meet the nuanced requirements of craft breweries and beverage businesses. With a focus on efficiency, adaptability, and precision, our machine sets the standard for excellence in the industry.

Key Technical Features:

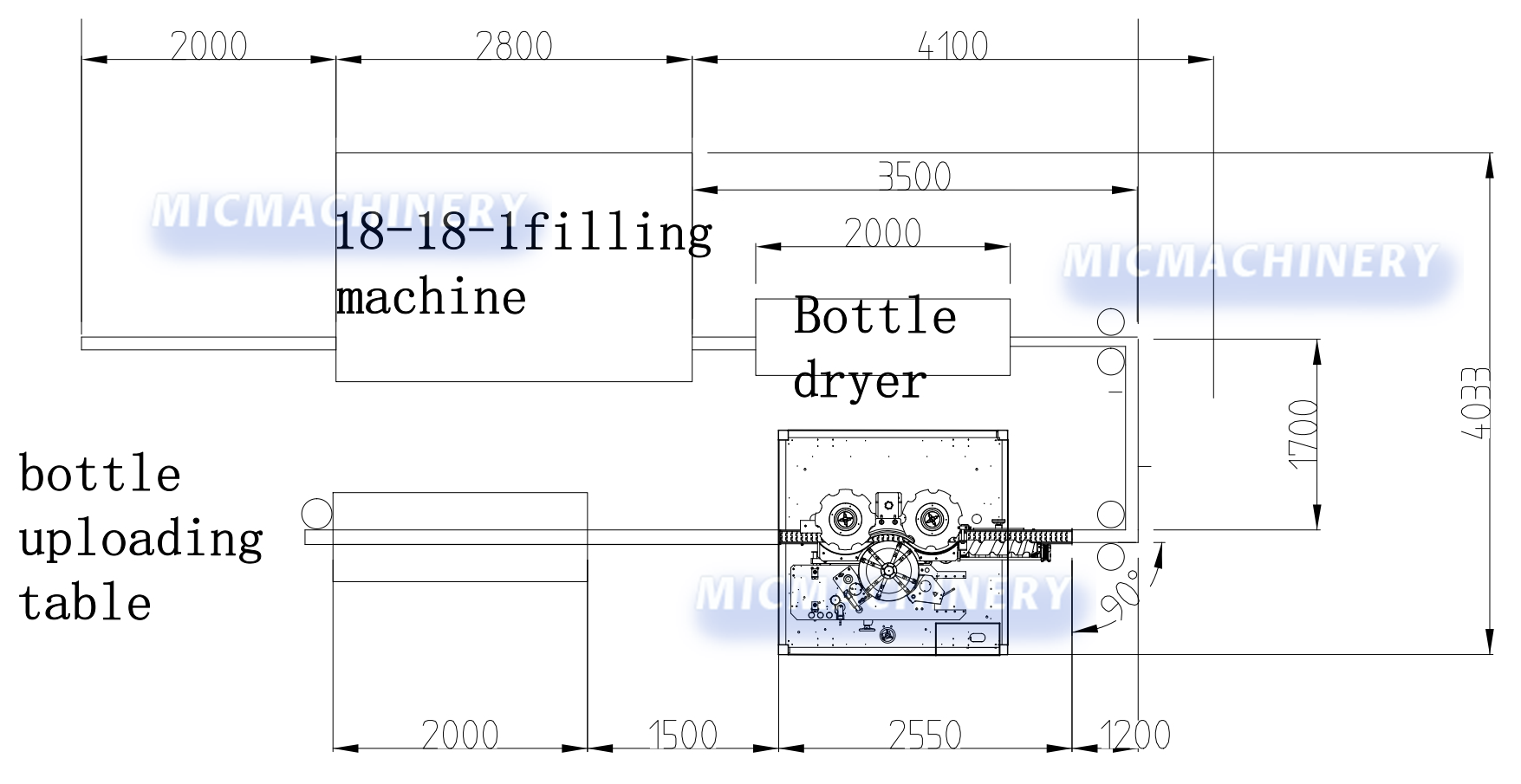

1. Compact Design:

Our small carbonated drink filling machine is crafted with a compact footprint, making it ideal for limited production spaces. This design ensures that small-scale producers can benefit from advanced beverage filling technology without compromising on space.

2. Versatility in Application:

Whether you're looking for a beer bottling machine for sale or reliable carbonated beverage bottling equipment, our solution adapts seamlessly to diverse production needs. It is capable of handling various types of carbonated drinks, ensuring flexibility for craft brewers and small-scale beverage producers.

3. Precision Filling Mechanism:

The heart of our machine lies in its precision filling mechanism. Engineered to deliver accurate fill levels for each bottle, this feature is essential for maintaining the quality and consistency of carbonated beverages, particularly in the craft brewing industry.

4. Efficient Capping System:

Beyond filling, our machine integrates an efficient capping system. This automated process ensures a secure seal for each bottle, preserving the carbonation levels and overall quality of the beverage.

Advantages for Small-Scale Producers:

1. Cost-Effective Solution:

Our small carbonated drink filling machine offers an economical option for small-scale producers, providing access to advanced filling technology without a prohibitive investment.

2. Streamlined Production:

The compact design and efficient workflow of our machine contribute to streamlined production processes. This is especially crucial for small-scale operations seeking to maximize output within limited resources.

3. Adaptability to Market Trends:

With the ability to handle diverse beverages, including craft beers and carbonated drinks, our machine allows small-scale producers to adapt to changing consumer preferences and market trends.

In conclusion, Mic Machinery is committed to empowering small-scale producers with our advanced small carbonated drink filling machine. Explore the possibilities of precision, adaptability, and efficiency in craft beverage production. Whether you're in search of a beer bottling machine for sale or reliable carbonated beverage bottling equipment, our solution is tailored to elevate your craft to new heights.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment