We sold one to France on June 25, 2022.

Machine Application

1. Diverse Soda Varieties:

Whether crafting classic colas or experimenting with unique soda formulations, our machines accommodate a wide array of soda varieties, providing a solution for every beverage producer.

2. Bottle Size and Shape Adaptability:

Designed for flexibility, our machines effortlessly handle various bottle sizes and shapes, empowering producers to diversify their product offerings in response to market demands.

3. Perfect for PET Bottles:

Engineered exclusively for PET bottles, our machines leverage the benefits of this lightweight, recyclable material, aligning with sustainability goals and industry trends.

Machine Advantages

1. Precision Filling Technology:

Our machines feature state-of-the-art precision filling technology, guaranteeing accurate fill levels for every bottle. This not only ensures product consistency but also minimizes waste, optimizing operational efficiency.

2. Versatility in Bottle Handling:

Whether choosing our rotary soda filling machine or the plastic bottle soda filling machine, both platforms showcase a remarkable versatility in handling various bottle sizes and configurations, allowing producers to meet evolving consumer preferences.

3. User-Friendly Controls:

With an intuitive control interface, our machines are designed for ease of operation, minimizing the learning curve for operators. This feature not only enhances overall production efficiency but also reduces downtime.

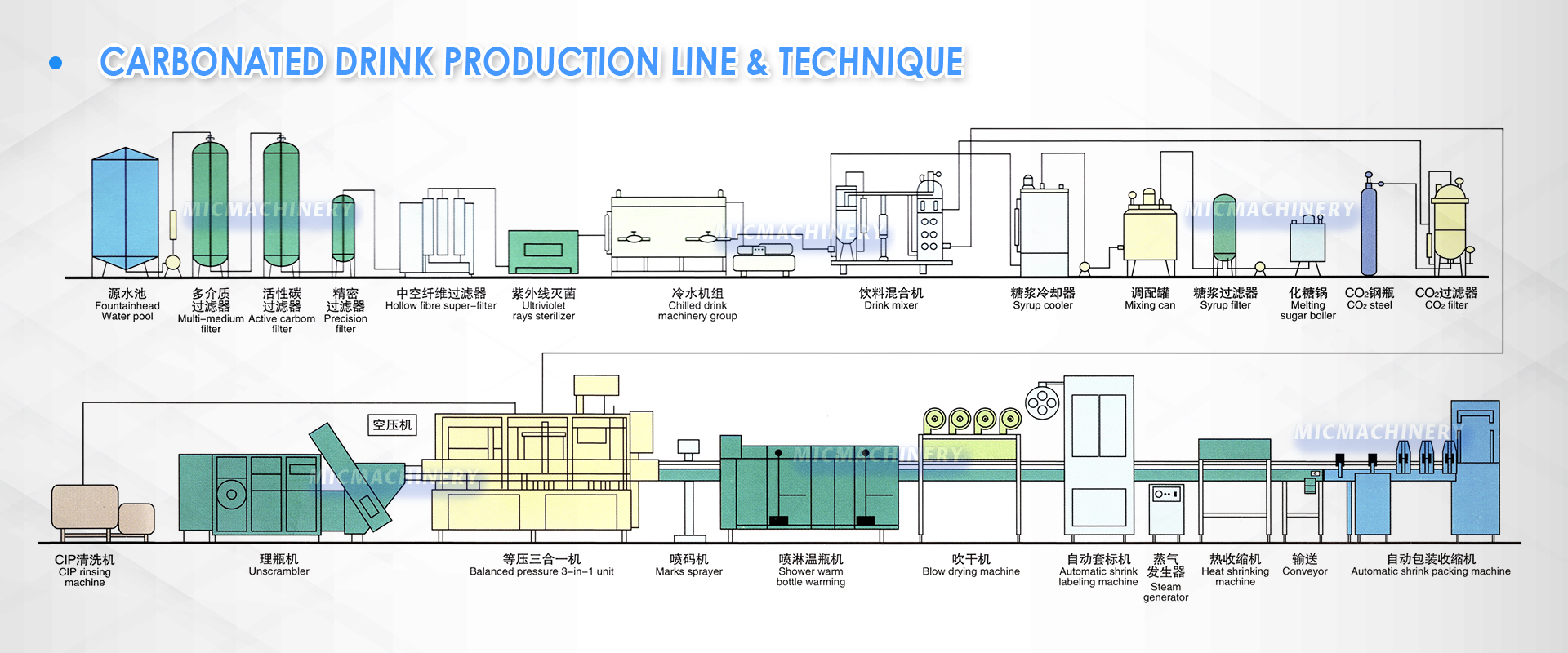

Machine Workflow

1. Bottle Feeding:

PET bottles are efficiently fed into the machine, initiating the soda filling and capping process.

2. Precision Filling:

Our machines utilize cutting-edge technology to ensure precise filling levels, maintaining the integrity of each product.

3. Capping Excellence:

The capping mechanism, whether integrated into our rotary soda filling machine or the plastic bottle soda filling machine, guarantees a secure seal for every bottle, preventing leaks and preserving product freshness.

4. Efficient Output:

Balancing speed and accuracy, our machines ensure a high output rate, addressing the demands of varying production scales.

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Keyword Integration:

1. Soda Filling and Capping Machine:

2. Rotary Soda Filling Machine:

Elevate your production capabilities with Mic Machinery's state-of-the-art rotary soda filling machines. The innovative rotary design ensures a continuous and smooth operation, significantly boosting throughput. This design not only enhances efficiency but also minimizes the risk of spillage and ensures consistent fill levels, contributing to a premium end-product.

3. Plastic Bottle Soda Filling Machine:

Key Features:

1. Precision Engineering:

At Mic Machinery, our soda filling and capping machines are crafted with precision engineering to guarantee accuracy in every fill. Equipped with advanced sensors and control systems, these machines maintain consistent fill levels, reducing product wastage and ensuring the delivery of beverages that meet the highest quality standards.

2. Customization Options:

3. User-Friendly Interface:

4. Hygienic Design:

In an era where innovation is paramount, Mic Machinery's rotary soda filling and capping machines represent the pinnacle of technological advancement in beverage packaging. By choosing our solutions, you not only invest in efficiency and precision but also align your brand with a commitment to sustainability and quality. Partner with Mic Machinery to unlock a new era of success in your bottling operations.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment