- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

In modern manufacturing environments, the role of case packers, particularly automated case packers, has become increasingly vital in streamlining packaging processes. These machines play a pivotal role in optimizing efficiency, accuracy, and throughput, ultimately driving productivity and enhancing customer satisfaction. Let's delve into how case packers, especially automated ones, demonstrate outstanding performance and why selecting the right case packer manufacturer is crucial.

Maximizing Efficiency with Automated Case Packers

Speed and Precision: Automated case packers operate at high speeds while maintaining precision in placing products into cases or containers. This level of efficiency minimizes downtime and significantly increases throughput, allowing manufacturers to meet demanding production targets.

Versatility and Adaptability: Automated case packers are designed to handle a wide range of product types, sizes, and packaging formats. Whether it's bottles, cartons, or pouches, these machines can accommodate various products, providing manufacturers with flexibility and adaptability to meet changing market demands.

Reduced Labor Costs: By automating the packaging process, automated case packers eliminate the need for manual labor in repetitive and labor-intensive tasks. This not only reduces labor costs but also minimizes the risk of errors and injuries associated with manual handling, ensuring a safer and more efficient work environment.

Importance of Choosing Reliable Case Packer Manufacturers

Quality and Reliability: Selecting reputable case packer manufacturers is crucial to ensuring the performance and longevity of the equipment. Established manufacturers with a proven track record offer high-quality machines built to withstand the rigors of continuous operation, minimizing downtime and maintenance costs.

Customization and Support: Leading case packer manufacturers understand that one size does not fit all. They offer customizable solutions tailored to specific production requirements and provide comprehensive support services, including installation, training, and ongoing technical assistance, to maximize machine performance and uptime.

Innovation and Technology: Top case packer manufacturers invest in research and development to incorporate the latest innovations and technological advancements into their machines. This commitment to innovation ensures that manufacturers have access to state-of-the-art equipment equipped with advanced features, enhancing efficiency, and productivity.

Conclusion

Automated case packers play a critical role in optimizing packaging efficiency, streamlining production processes, and ensuring product quality and consistency. By partnering with reputable case packer manufacturers, manufacturers can access high-quality, reliable machines that meet their specific needs and drive operational excellence. Investing in automated case packing technology not only enhances efficiency and productivity but also positions manufacturers for long-term success in today's competitive market landscape.

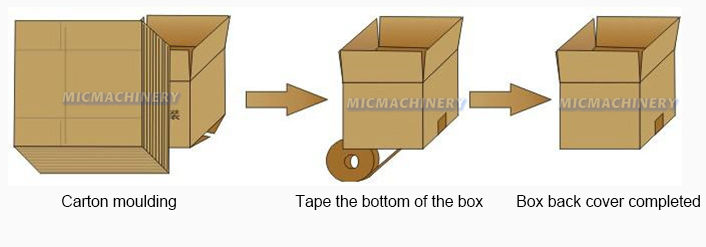

1.Automatic carton unpacker(photo for reference)

◆ Major characteristics:

1. Imported components, electric and pneumatic parts.

2. Vertical cardboard mechanical, add cardboards whenever necessary without stopping the machine.

3. Manually adjust for different cartons within allowable range, just takes 1~2 minutes.

4. Reasonable design, vacuum cup suck the cardboard, fold and seal the bottom.

5.Small space occupation, precision and durable parts provide the gaurantee for stable running, long life, and high efficiency.

6. with protection device for cutter installation to avoid being hurt.

7.Easy operation, machine can be used individually and combined with the packaging line.

◆ 2.Automatic case packing machine

carton case packer. The grabbing type case packer is reliable in operation: This machine is realized by the servo to pick up and release the product. Through the mechanical operation, pneumatic and electric control, the product can be accurately and reliably picked up from the box holder with a suction cup into the carton.

◆ Technical parameter

1. Equipment production capacity: standard output 15-17 carton/minute.

2. Packing: 3*4bottles/carton (customerize)

3. Applicable box type: need define Weight: need define

4. Packing layer: one layer

5. Machine size: length 3540* width 1480* height 2100(mm)

6. equipment power:220V 50/60Hz or 3 P 415v 50/60Hz 5.5KW

7. Compressed air: 0.6 ~ 0.8Mpa, 350NL/min, Trachea interface: Φ12

8. Equipment weight: 1200 kg

◆ Major characteristics:

1. Carton packing machine is used for packaging finished gooder in cartons.

2. It's small, beautiful, stable, economical and convenient.

3. The loading part drive with non-pole cylinder is stable, exactable and high adjust.

4. The gripper drive with servo motor is exactable, stable and safe.

Technical parameter

|

Carton size |

L260-535* W260-420*H130-330 |

|

Speed |

17 carton/min(according to the carton size) |

|

Dimension |

1950*1500*1450mm |

|

Power supply |

220V;50Hz |

|

Table high |

Min 600mm; Max 720mm |

|

Tape width |

45~72mm |

|

weight |

400kg |

Electrical configuration

|

Name |

Model |

Amount |

Brand |

Origine |

|

Miniature circuit breaker |

4P C20 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

1P C10 |

1 |

Schneider |

France |

|

A.C.contactor |

E1810 |

1 |

Schneider |

France |

|

A.C.contactor |

E09104 |

3 |

Schneider |

France |

|

Emergency stop |

LAY7-11ZS/R |

1 |

Schneider |

France |

|

Switching power supply |

S8JC-Z05024C |

1 |

Schneider |

France |

|

Relay |

MY2NJ 24VDC |

1 |

Schneider |

France |

|

PLC |

SIMATIC S7-200 |

1 |

Siemens |

Germany |

|

Touch screen |

SMART 700 IE V3 |

1 |

Siemens |

Germany |

|

Frequency transformer |

SINAMICS V20 |

1 |

Siemens |

Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment