Product Usage

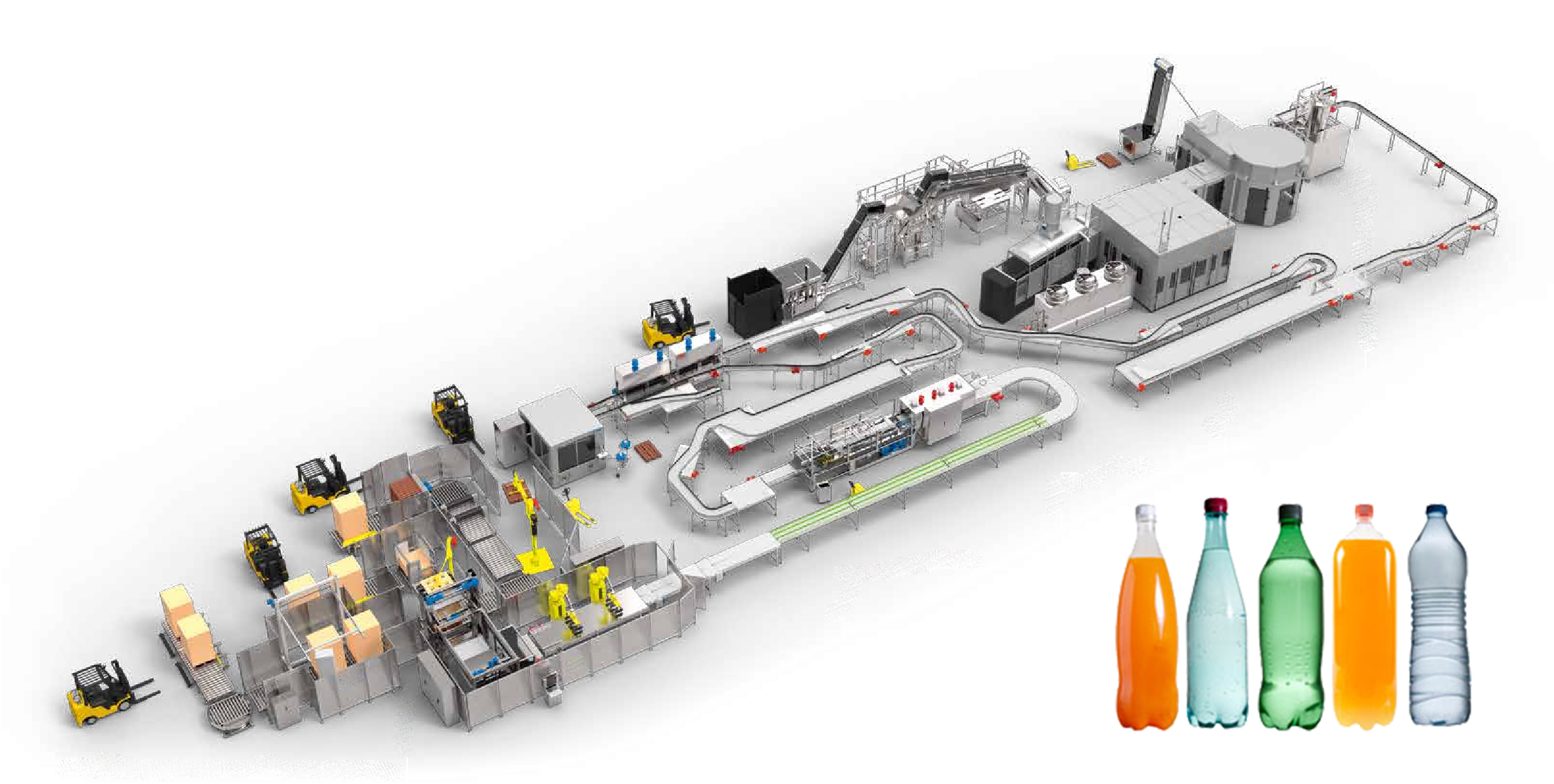

1. Beverage Bottling Line:

At the heart of our portfolio lies the dynamic beverage bottling line, designed for a myriad of beverage types. Whether your production focuses on carbonated drinks, still beverages, or a combination of both, our beverage bottling line seamlessly adapts to diverse liquid products.

2. Beverage Filling Production Line:

The beverage filling production line by Mic Machinery is a holistic solution catering to the end-to-end needs of beverage manufacturers. From precise filling to secure capping and packaging, this line is engineered for efficiency, ensuring a streamlined and cost-effective production process.

3. Syrup Bottling Line:

Tailored for the syrup manufacturing industry, our dedicated syrup bottling line stands as a testament to precision in every drop. This line caters to the unique viscosity and characteristics of syrups, offering a customizable solution for varying bottle sizes and packaging requirements.

Machine Characteristics

1. Adaptable Configuration:

Mic Machinery's beverage filling production line boast adaptable configurations, ensuring seamless integration into diverse production environments. Whether you require a compact setup for limited space or a high-speed solution for large-scale production, our machines cater to your specific needs.

2. State-of-the-Art Technology:

Immerse yourself in the epitome of technological innovation. Our machines are characterized by state-of-the-art technology, incorporating automated systems, precision control mechanisms, and intuitive interfaces. This commitment to technological excellence enhances overall efficiency and reliability.

3. Customizable Design:

Recognizing the uniqueness of each beverage filling production line, our machines feature customizable designs. From bottle handling systems to filling stations, we offer flexibility to tailor the machine characteristics according to the specific requirements of your beverage manufacturing processes.

Mechanical Classification

1. Automated Filling Mechanisms:

The technical principles governing Mic Machinery's beverage bottling line revolve around automated filling mechanisms. This ensures consistent fill levels, minimizing variations and contributing to a final product that meets the highest quality standards.

2. Integrated Quality Control:

Quality is paramount in beverage manufacturing. Our syrup bottling line incorporate integrated quality control measures at every stage of the process, ensuring that only bottles meeting stringent standards progress through the production line.

3. Material Compatibility Considerations:

Mic Machinery's technical principles are founded on material compatibility considerations. Whether handling glass, PET, or other materials, our machines are designed to optimize performance while preserving the integrity of the chosen packaging material.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 800-1500BPH

Speed: 5000-12000BPH

Speed: 2000-3000BPH

Speed: 3000-5000BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 8000-10000BPH

Speed: 1800BPH

Speed: 3000-5000BPH

Speed: 5000-12000BPH

Speed: 14000BPH

Welcome to Mic Machinery, a trailblazer among beverage filling machine manufacturers, where innovation, precision, and reliability converge to redefine the landscape of beverage packaging. In this technical introduction, we invite you to explore our comprehensive expertise as creators of cutting-edge solutions. Specializing in crafting bespoke beverage filling machines and complete production lines, including the sought-after beverage bottling line and syrup bottling line, Mic Machinery stands as a testament to unwavering commitment and ingenuity.

At Mic Machinery, our journey as beverage filling machine manufacturers is characterized by a commitment to craftsmanship and technological advancement:

1. Innovative Beverage Filling Machines:

Our portfolio boasts a diverse range of innovative beverage filling machines, meticulously designed to cater to the evolving needs of the industry. From compact solutions for startups to high-speed, high-capacity machines for established manufacturers, we pride ourselves on delivering versatility and efficiency.

2. Tailored Solutions for Every Beverage:

Recognizing the diverse spectrum of beverages in the market, our machines are engineered to handle a variety of liquid products. Whether it's carbonated drinks, still beverages, or syrups, our beverage filling machines are adaptable to different viscosities and packaging requirements.

3. Cutting-Edge Technology Integration:

At the core of our machines lies cutting-edge technology, seamlessly integrated to enhance efficiency and precision. From automated filling processes to advanced control systems, Mic Machimery is at the forefront of technological innovation in the beverage filling industry.

Beverage Bottling Line: Streamlining Production with Precision

Our commitment to excellence extends beyond individual machines to encompass complete production lines, with a spotlight on the beverage bottling line:

1. Integrated Bottle Handling Systems:

Our beverage bottling lines feature integrated bottle handling systems that ensure a smooth and efficient flow from the initial bottle placement to the final packaging stage. This comprehensive approach minimizes downtime and maximizes production output.

2. Efficient Filling Stations:

Filling stations within our beverage bottling lines are equipped with state-of-the-art technology, allowing for precise and consistent filling. This not only maintains the quality of the beverage but also contributes to cost-effective production.

3. Seamless Capping and Packaging:

The culmination of our beverage bottling line is in the seamless capping and packaging stages. These critical components are meticulously designed to secure product freshness and uphold the integrity of the packaging, ensuring a final product that meets the highest industry standards.

For those in the syrup manufacturing industry, Mic Machinery introduces a dedicated syrup bottling line:

1. Specialized Syrup Handling Systems:

Our syrup bottling lines feature specialized systems for handling syrups with varying viscosities. Precision is paramount, and our machines are equipped to delicately handle the unique characteristics of syrup products.

2. Accurate Metering and Filling:

The metering and filling stages in our syrup bottling lines are calibrated to ensure accurate volumes with every cycle. This precision guarantees consistency in flavor profiles and product quality, meeting the stringent requirements of the syrup industry.

3. Customizable Configurations:

Recognizing the diverse array of syrup products, our syrup bottling lines are customizable in configuration. Whether it's different bottle sizes or specific packaging requirements, our solutions can be tailored to suit the unique demands of syrup manufacturers.

In conclusion, at Mic Machinery, we transcend the role of mere beverage filling machine manufacturers. We are architects of efficiency, precision, and innovation, offering a comprehensive suite of solutions that redefine the standards of beverage packaging. Join us at Mic Machinery, where craftsmanship meets cutting-edge technology, and every drop tells a story of excellence in beverage packaging. Explore the possibilities with Mic Machinery, your trusted partner in the pursuit of unparalleled beverage filling solutions.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

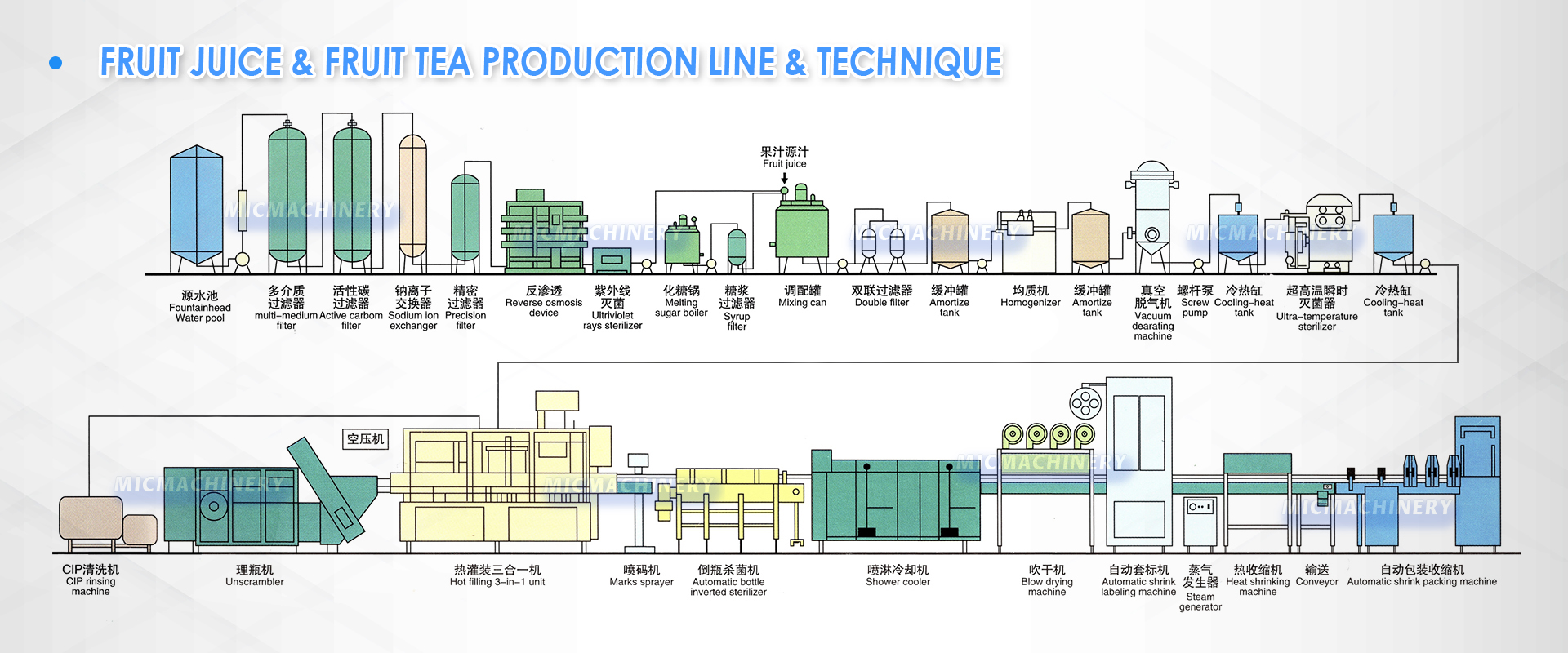

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment