Machine Advantages

1. Experience Efficiency Redefined:

At Mic Machinery, our bottling lines introduce a new era of efficiency. Automated processes minimize manual intervention, ensuring seamless operations and maximizing production speed. Benefit from advanced features that streamline the entire bottling process, guaranteeing precision at every stage.

2. Adaptability and Scalability:

Our small bottling lines set the standard for adaptability. Purposefully designed for limited spaces, these machines don't compromise on technological sophistication. The scalability of our solutions caters to businesses of all sizes, offering flexibility for both boutique producers and established enterprises.

3. Precision Engineering at Its Finest:

Precision is not just a goal; it's our hallmark. Our bottle filling line equipment ensures accurate fills and secure capping through advanced mechanisms. Consistent quality is maintained, contributing to the impeccable presentation of your products in the market.

Product Usage

1. Small Bottling Line Excellence:

Tailored for businesses seeking efficiency in limited spaces, our small bottling lines provide a compact yet powerful solution. Perfect for boutique producers, these lines maintain the highest standards of quality in every bottle, ensuring a seamless production process.

2. Versatile Applications for Every Industry:

Explore the versatility of our bottle filling line equipment, catering to a diverse range of industries. Whether in beverages, pharmaceuticals, or cosmetics, our adaptable equipment aligns with your specific production needs, offering a solution that transcends boundaries.

Technical Principle

1. Advanced Sensors and Controls:

Integrated sensors detect minute variations, allowing for real-time adjustments to maintain consistent filling levels and capping pressure.

2. Flow Control Mechanisms:

Sophisticated flow control mechanisms regulate the speed and volume of liquid dispensing, optimizing the filling process for different bottle sizes and types.

3. Quality Assurance Features:

Built-in quality assurance features detect and address issues such as underfills or overfills, ensuring that every bottle meets the highest standards of quality.

4. Customizable Settings:

User-friendly interfaces empower operators to customize settings based on the specific requirements of different products, providing a tailored approach to each bottling run.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Bottling Line Manufacturers: A Technical Marvel:

Small Bottling Line Solutions:

Cutting-Edge Bottle Filling Line Equipment:

Key Features of Mic Machinery Solutions:

1. Scalable Technology:

• Our bottling lines are scalable, catering to businesses of varying sizes and production capacities.

• Adaptable solutions for small-scale producers ensure efficiency without compromising on precision.

• Small bottling lines designed with the unique challenges of boutique producers in mind.

• Compact footprint without sacrificing the technological sophistication required for high-quality bottling.

• Accommodate a diverse range of bottle sizes and types, allowing for flexibility in product offerings.

• Versatile solutions suitable for a variety of industries, from beverage producers to specialty product manufacturers.

1. Technical Expertise:

Our team of experts brings a wealth of technical knowledge to ensure our solutions meet and exceed industry standards.

We are committed to innovation, continuously refining our bottling lines to stay ahead of evolving production requirements.

3. Customer-Centric Approach:

Mic Machinery prioritizes customer satisfaction, offering personalized solutions that align with the unique needs of each client.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

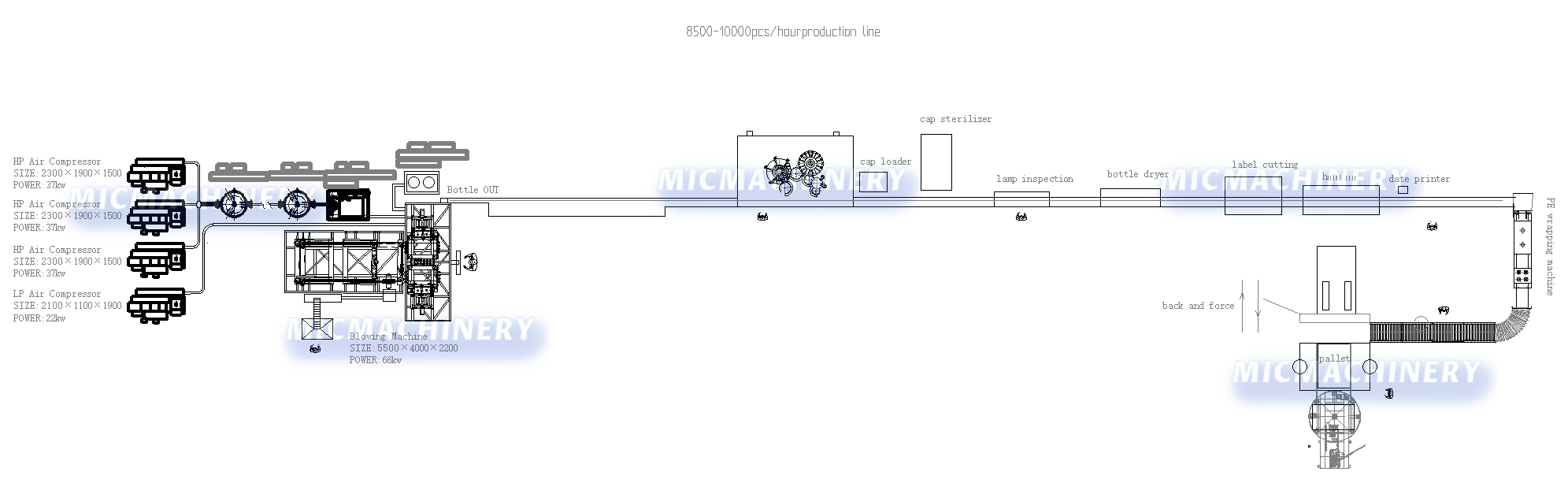

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

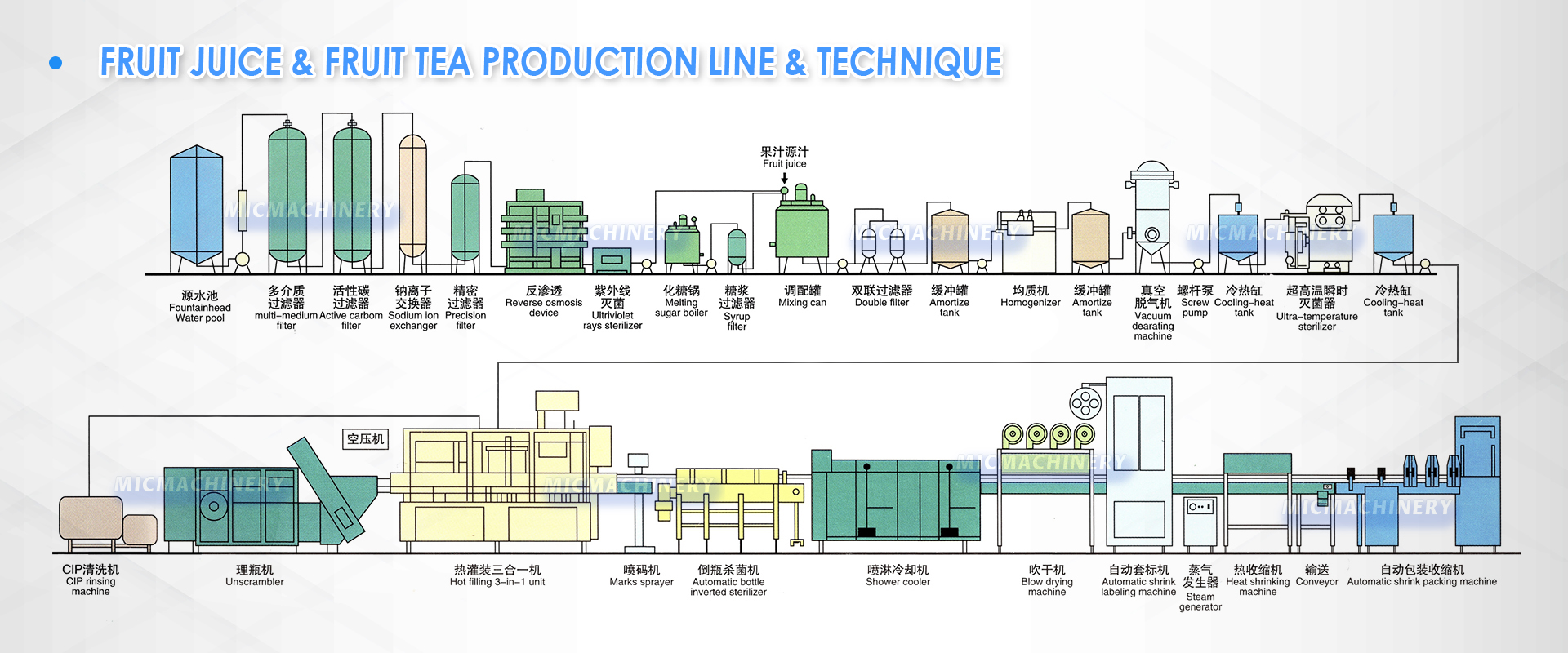

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment