Machine Characteristics

1. Versatility for Various Beverages:

Mic Machinery's soft drink canning machines are engineered for versatility, effortlessly adapting to the production of both traditional soft drinks and energy beverages. This characteristic makes our machines an ideal choice for producers looking to diversify their product offerings.

2. Precision in Liquid Filling:

Experience unparalleled precision with our automatic soft drink filling machines. Equipped with cutting-edge liquid filling technology, these machines ensure precise and consistent filling levels in every can, setting the standard for beverage quality in the industry.

Product Application

1. Crafting Traditional Soft Drinks:

Elevate your soft drink production with [Your Company Name]'s soft drink canning machines. These machines are meticulously designed to handle the unique characteristics of traditional soft drinks, maintaining the effervescence and flavor profiles that consumers love.

2. Energy Drink Filling Expertise:

Venture into the dynamic energy drink market with confidence using our specialized soft drink canning machines. Tailored to accommodate the distinctive features of energy beverages, our technology ensures efficient filling, preserving the unique attributes of these high-demand products.

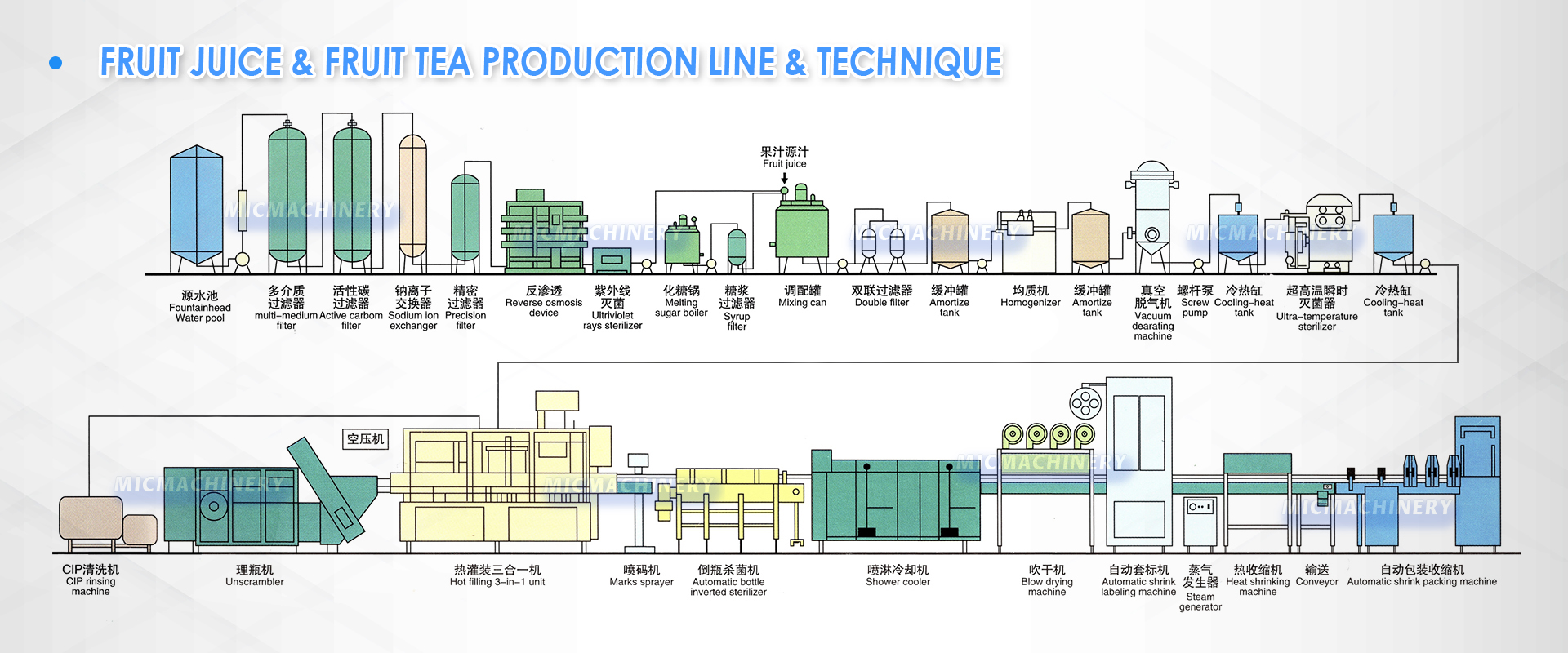

Streamlined Machine Workflow

1. Smart Automation for Operational Efficiency:

Boost operational efficiency with the smart automation features integrated into our soft drink can filling machines. From liquid dispensing to can sealing, these automated systems streamline the filling process, reducing manual labor and optimizing the overall workflow for maximum productivity.

2. Adaptable Technology for Diverse Production Needs:

Embrace adaptability with Mic Machinery's soft drink canning machines. These machines are designed to accommodate various can sizes, ensuring flexibility in production. The adaptable technology contributes to a seamless workflow that caters to the dynamic needs of modern beverage manufacturing.

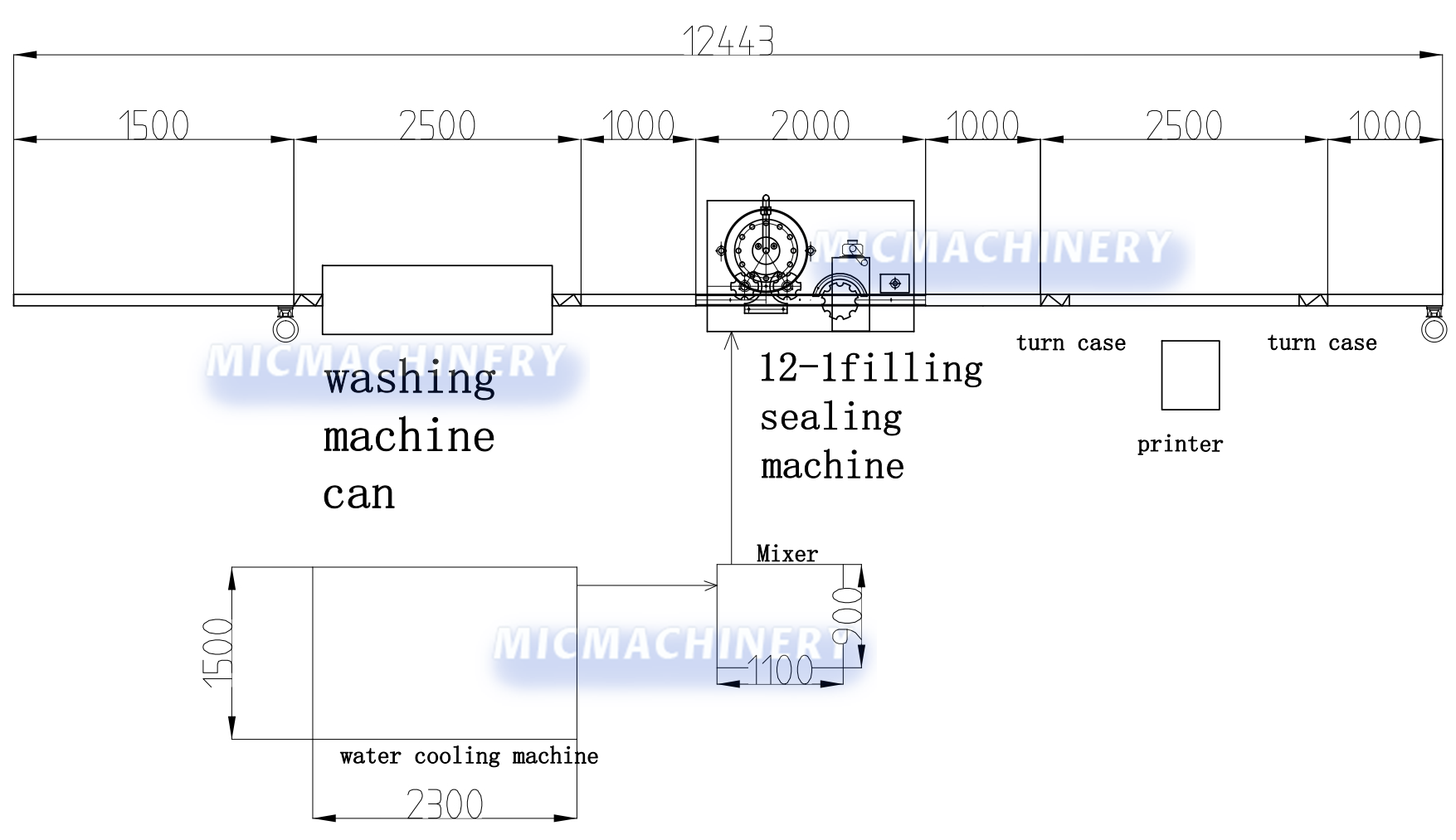

Speed: 1000-2000CPH

Speed: 480CPH

Welcome to the pinnacle of innovation in beverage production with Mic Machinery, distinguished leaders in soft drink canning machines. As industry experts, we introduce cutting-edge technology through our automatic soft drink filling machines, designed to redefine the standards of efficiency and precision. Explore the technical brilliance, adaptability, and advantages that make our soft drink can filling machines the go-to choice for producers in the beverage industry.

Innovative Soft Drink Canning Machines:

1. Versatility for a Range of Beverages:

Mic Machinery's soft drink canning machines are engineered for versatility, catering not only to traditional soft drinks but also to a spectrum of beverages, including energy drinks. The adaptability of our machines ensures seamless production for diverse beverage types.

2. Precision in Every Can:

Experience precision at its finest with our automatic soft drink filling machines. Equipped with cutting-edge liquid filling technology, our machines guarantee accurate and consistent filling levels in every can, setting unparalleled standards for beverage quality.

Adaptive Technology for Energy Drinks:

1. Energy Drink Filling Expertise:

Dive into the energy drink market with confidence using our specialized soft drink canning machines. Crafted to handle the unique characteristics of energy drinks, our technology ensures efficient filling, preserving the distinct features and effervescence of these beverages.

2. Smart Automation for Seamless Operations:

Enhance operational efficiency with the smart automation features embedded in our machines. From liquid dispensing to can sealing, our automated systems streamline the soft drink can filling process, reducing manual labor and optimizing the overall workflow for maximum productivity.

Technical Excellence Unveiled:

1. Cutting-Edge Liquid Filling Technology:

At the heart of our soft drink can filling machines lies cutting-edge liquid filling technology. This advanced mechanism guarantees precise and consistent liquid levels in every can, ensuring that each product meets the highest industry standards for quality.

2. Intelligent Control Systems for Reliability:

Our machines are equipped with intelligent control systems, ensuring reliability throughout the soft drink can filling process. These systems optimize operational parameters, contributing to a stable and reliable workflow that minimizes errors and enhances overall efficiency.

Why Choose Mic Machinery for Soft Drink Canning:

1. Industry Leadership and Expertise:

Mic Machinery stands as an industry leader in soft drink canning machines, backed by years of expertise and a track record of excellence. Our machines are trusted by producers worldwide for their reliability, precision, and innovative design.

2. Comprehensive Solutions for Various Beverages:

Whether you're producing traditional soft drinks or venturing into the dynamic energy drink market, Mic Machinery offers comprehensive solutions. Our soft drink canning machines are adaptable to a range of beverage types, providing versatility for your production needs.

In conclusion, Mic Machinery doesn't just provide soft drink can filling machines; we deliver technological solutions that redefine efficiency and precision in beverage production. Elevate your operations, embrace innovation, and choose Mic Machinery as your strategic partner. Contact us today to embark on a journey of technical mastery and success in soft drink canning.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment