Efficient and Automated Beverage Packaging Solutions

Our Beverage Packaging Machine is designed to streamline the final packaging process of bottled and canned beverages. Whether you're working with juice, soda, water, or energy drinks, this machine automates the packaging process to ensure safe, efficient, and hygienic packaging, all while maintaining the integrity of your product.

What is a Beverage Packaging Machine?

A Beverage Packaging Machine automates the process of sealing and preparing bottled and canned beverages for retail. After filling and capping, the machine efficiently packs products into cartons, shrink-wraps, or other packaging formats based on your specific needs. It is a key component in beverage production lines, ensuring high-speed operation and minimal manual labor.

These machines are ideal for beverage manufacturers who need to quickly and safely package large volumes of products, maintaining hygiene standards while offering flexibility in packaging formats.

More Gas Drink Can Model And Speed Click

|

Model |

MIC 12-1 |

MIC 18-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

MIC 4-4-1 |

MIC semi automatic |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water, And So On |

|||||||

|

Packing Type |

Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc |

|||||||

|

Speed |

1000-2000 CPH |

1000-2500 CPH |

3000-6000 CPH |

4000-8000 CPH |

6000-10000 CPH |

8000-15000 CPH |

1000-1500 CPH |

|

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

|||||||

|

Power |

1.1kw |

1.5kw |

2.5kw |

3.5kw |

4.2kw |

5.5kw |

2.0-3.5kw |

|

|

Size |

1.8*1.3*1.95 (M) |

1.9*1.3*1.95 (M) |

2.3*1.4*1.9 (M) |

2.58*1.7*1.8 (M) |

2.8*1.7*1.95 (M) |

3.0*1.9*2.1 (M) |

2.2*1.15*2.05 (M) |

5.75*5.5*4.8 (M) |

|

Weight |

1800KG |

2100KG |

2500KG |

3000KG |

3800(KG) |

4500(KG) |

550(KG) |

15(KG) |

More Gas Drink Bottle Model And Speed Click

|

Model |

MIC12-12-1 |

MIC18-18-1 |

MIC18-18-6 |

MIC24-24-6 |

MIC24-24-8 |

MIC32-32-8 |

MIC semi automatic |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water, And So On |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, Pet Bottle Etc |

||||||

|

Speed |

300-1500BPH |

1000-2500BPH |

2000-4000BPH |

4000BPH |

2000-6000BPH |

4800-7500BPH |

200-800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

|

Power |

|

|

2.2kw |

1.5kw |

1.5kw |

5.0kw |

0.3kw |

|

Size |

|

|

2.5*1.9*2.3 (M) |

2.2*1.8*2.55 (M) |

2.5*1.4*2.5 (M) |

3.4*2.5*2.3 (M) |

2.0*0.7*2.0 (M) |

|

Weight |

|

|

3500KG |

3500KG |

4500KG |

10000KG |

150KG |

More Non Gas Drink Bottle Model And Speed Click

|

Model |

MIC 12-1 |

MIC 8-8-3 |

MIC 14-12-5 |

MIC 18-18-6 |

MIC 18-18-6 |

MIC 24-18-6 |

MIC Linear |

|

Application |

Juice, cold coffee, herbal tea, non-carbonated drinks and so on |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, Pet Bottle Etc |

||||||

|

Speed |

500-2000BPH |

2000-2500BPH |

3000-5000BPH |

8000-15000BPH |

8000-10000BPH |

10000-13000BPH |

1800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

More Non Gas Drink Can Model And Speed Click

|

Model |

MIC 12-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

|

Application |

Juice, cold coffee, herbal tea, non-carbonated drinks and so on |

||||

|

Packing Type |

Aluminum cans, tin cans, pet cans, etc |

||||

|

Speed |

1000-2000CPH |

4000-7000CPH |

4000-8000CPH |

10000CPH |

12000CPH |

|

Filling Arrange |

130ml,250ml, 330ml, 355ml, 500ml, 120z, 16oz, 1L and so on (0.1-1L) |

||||

|

Powder |

1.1kw |

2.5kw |

3.5kw |

4.2kw |

5.5kw |

|

Size |

1.8*1.3*1.95 (M) |

2.3*1.4*1.9(M) |

2.58*1.7*1.8(M) |

2.8*1.7*1.95(M) |

3.0*1.9*2.1(M) |

|

Weight |

1800KG |

2500KG |

3000KG |

3800(KG) |

4500(KG) |

Beverage Packaging Machine Manufacturer

- High-Speed Operation

- Flexible Packaging Formats

- Adaptable to Different Can/Bottle Sizes

- Stainless Steel Construction

- User-Friendly Control System

- Energy Efficient

Technical Introduction to Beverage Packaging Machines

Beverage Packaging Machine

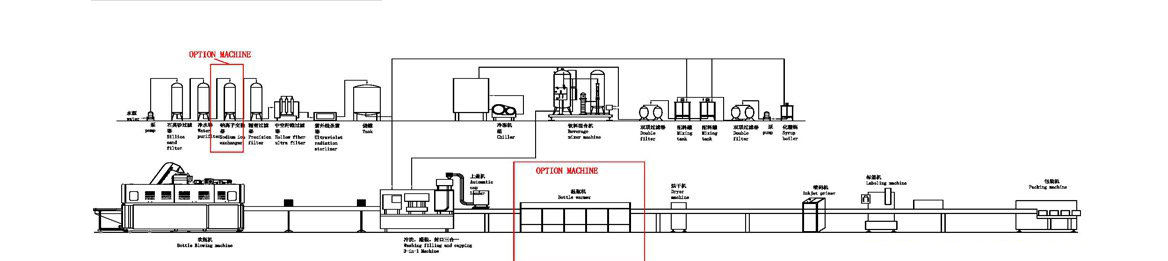

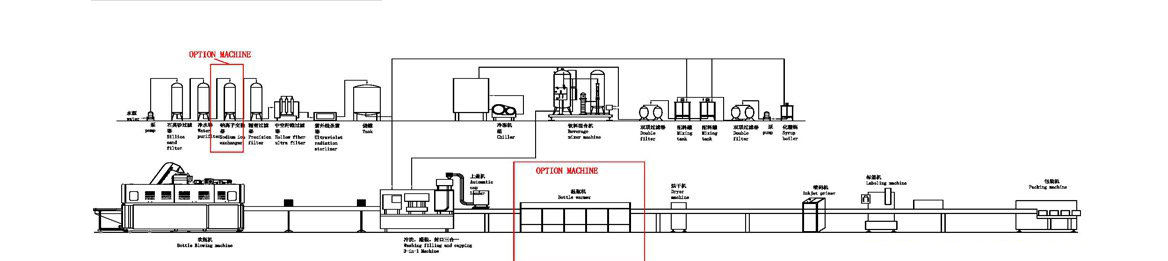

A beverage packaging machine is specifically designed to handle the complexities of packaging liquid products. These machines automate various tasks, including filling, capping, labeling, and sealing, ensuring that each bottle or can is properly prepared for distribution. The performance of a beverage packaging machine is critical; it must operate efficiently to minimize downtime and reduce waste. Advanced technologies such as sensor systems and automated controls help ensure precision, resulting in high-quality packaging that meets industry standards.

Beverage Packaging Equipment

Beverage packaging equipment encompasses a wide range of machines and tools involved in the packaging process. This includes not only filling machines but also capping machines, labeling systems, and conveyors. By integrating various types of beverage packaging equipment, manufacturers can create streamlined production lines that enhance overall efficiency. The flexibility and scalability of this equipment allow companies to adjust their production rates in response to market demand, making it easier to manage fluctuations in output without compromising quality.

The term food and beverage packaging machinery refers to machines that are designed for both food and liquid products. This machinery must adhere to strict hygiene standards and regulations, ensuring that products remain safe and uncontaminated throughout the packaging process. The performance of food and beverage packaging machinery is paramount; it must be reliable, easy to clean, and capable of handling various packaging formats. Investing in high-quality machinery not only improves production efficiency but also enhances brand reputation by delivering safe, high-quality products to consumers.

Conclusion

Investing in effective beverage packaging machines and beverage packaging equipment is essential for manufacturers aiming to optimize their production processes. The integration of advanced food and beverage packaging machinery ensures that products are packaged efficiently, maintaining quality and compliance with industry standards. By choosing the right equipment, beverage manufacturers can enhance their operational capabilities, reduce costs, and improve their market presence, ultimately leading to greater customer satisfaction and loyalty.

Investing in a beverage packaging machine is a strategic decision that can bring numerous benefits to beverage manufacturers. These machines offer a significant increase in production efficiency, allowing for higher output and faster packaging processes. With their automated capabilities, beverage packaging machines reduce the need for manual labor, minimizing the risk of human error and ensuring consistent results.

Maintenance and support are crucial aspects to consider when investing in beverage packaging machines. These machines require regular upkeep to ensure optimal performance and longevity. Reputable manufacturers provide comprehensive maintenance guidelines and offer reliable technical support. Scheduled maintenance routines, including cleaning, lubrication, and inspection, help prevent breakdowns and optimize machine performance. It is essential to partner with a supplier who offers readily available spare parts and responsive customer service to minimize downtime and maximize the productivity of the beverage packaging machine.