Blowing Filling Capping Machine | Zhangjiagang Micmachinery

The global beverage and packaging industries are rapidly evolving, demanding more efficient, compact, and hygienic equipment. At Zhangjiagang Micmachinery, we specialize in designing and manufacturing high-performance blowing filling capping machine solutions for PET bottle packaging lines. Our equipment offers a smart combination of innovation, energy efficiency, and cost-effectiveness.

What Is a Blowing Filling Capping Machine?

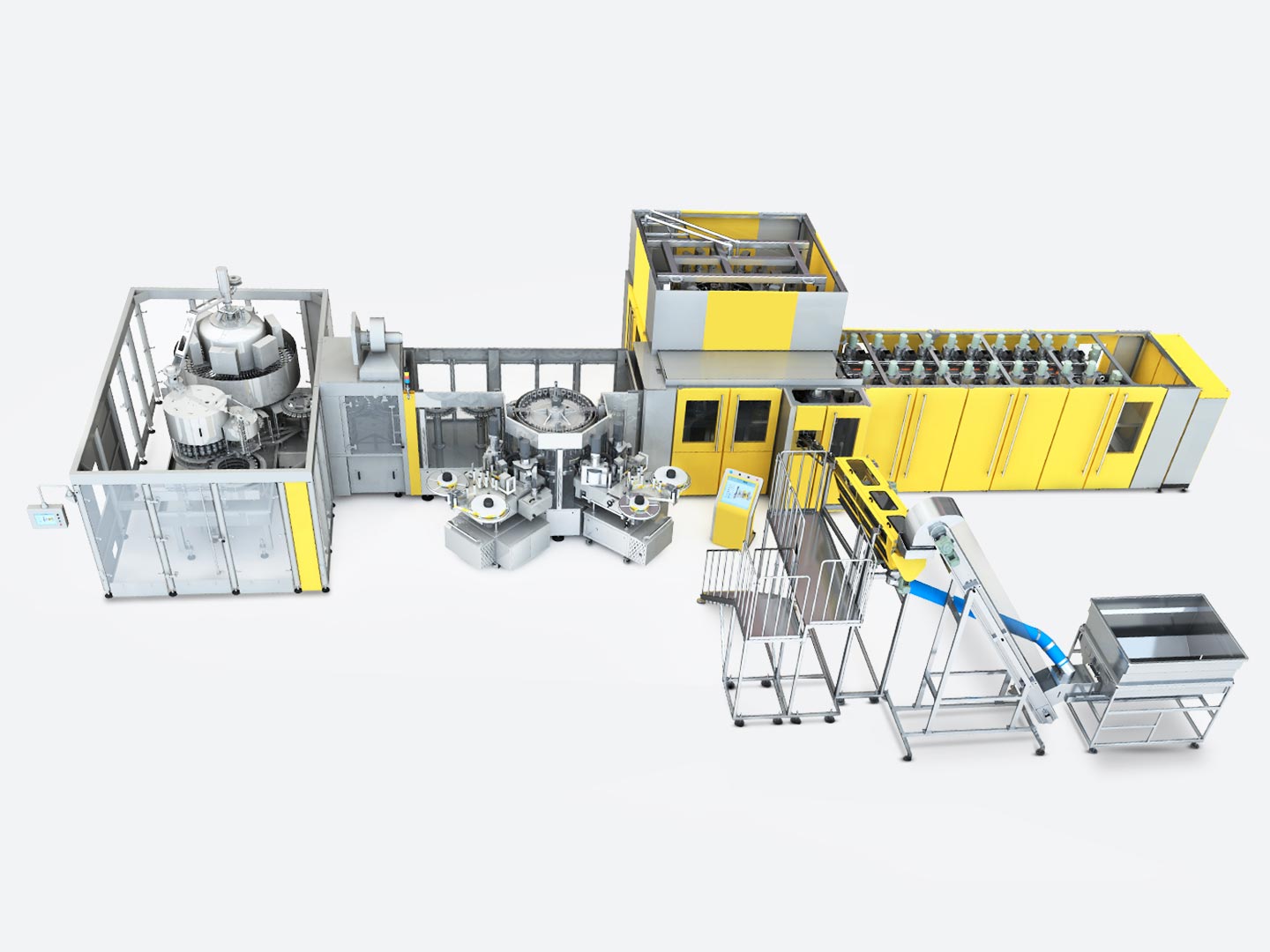

A blowing filling capping machine is an integrated system that combines three key processes: bottle blowing, liquid filling, and cap sealing. Traditionally, these steps required separate machines and manual or robotic transfers. The integrated design eliminates those transitions, reducing contamination, improving efficiency, and saving space.

This type of blowing-filling-capping machine is ideal for water, juice, dairy, and other non-carbonated beverage production. The solution is often referred to as a combi-block blowing filling capping machine, representing a new generation of compact bottling technologies.

Features of the Combiblock System

The combiblock blowing filling capping machine is designed with flexibility and cleanliness in mind. Built in a closed chamber with laminar airflow and positive pressure, it prevents airborne contaminants from entering the filling area. This is crucial for hygiene-critical applications like milk or flavored water.

Each blowing filling capping 3 in 1 machine supports multiple bottle volumes and neck finishes. It allows rapid mold changes, fast sanitization, and highly synchronized automation—helping factories maximize uptime while maintaining product safety.

PET Bottle Applications Across Industries

One of the most common applications is the PET bottle blowing filling capping machine, used in the bottled water industry. It can produce lightweight, high-clarity bottles on-site, fill them with sterile liquid, and seal them—all in one smooth motion.

Our PET bottle systems accommodate 200ml to 2-liter containers and offer temperature-controlled preform heating, adjustable filling levels, and torque-monitored capping for leak prevention.

Whether you’re bottling natural spring water or vitamin-enriched beverages, our automatic blowing filling capping machine offers reliable performance and long service life.

Fully Automated and User-Friendly

The automatic blowing filling capping machine from Micmachinery is designed for 24/7 industrial operation. Controlled by advanced PLC systems with touch-screen HMI panels, it allows operators to manage every parameter with ease—temperature, pressure, speed, volume, and capping force.

Our blowing-filling-capping combi machine is equipped with real-time monitoring, error alarms, and remote diagnostics to reduce downtime and optimize maintenance. Sanitary features include UV sterilization for caps and ionized air for preforms.

How Our Equipment Fits Your Production Line

The modular structure of our combi systems means they can be seamlessly integrated into your existing layout or included in a brand-new factory plan. From bottle unscramblers to carton packers, we provide turnkey solutions tailored to your beverage product and packaging goals.

If you're building a water factory or launching a new drink brand, a blowing-filling-capping combi machine ensures speed, hygiene, and space savings without compromising quality.

Technical Specifications and Customization

Our combiblock blowing filling capping machine lines offer:

• Production speeds from 2,000 to 36,000 bottles per hour

• Mold compatibility for 250ml to 2L PET bottles

• Gravity, hot-fill, or isobaric filling modules

• Aluminum or plastic cap compatibility

• Options for sparkling water or juice with pulp

You can customize your machine with extra rinsing stations, HEPA filtration, neck handling conveyors, and CIP systems. Each blowing filling capping 3 in 1 machine is factory-tested and delivered with full documentation and training.

| Number of Working Positions | Blowing 8, Filling 32, Capping 10 |

| Rated Capacity | 18000BPH (600ml) |

| Filling Method | Gravity Filling |

| Applicable Bottle | PET bottle |

| Diameter of bottle: Φ50~Φ92mm | |

| Height of bottle: 150-320mm | |

| Applicable Cap | Normal Standard Cap |

| Installed Power | 200KW |

Why Choose Zhangjiagang Micmachinery?

We are a trusted Chinese manufacturer with years of experience serving international clients. Our PET bottle blowing filling capping machine lines are CE-certified, competitively priced, and backed by global after-sales support.

Zhangjiagang Micmachinery stands out for:

• Strong R&D and design customization

• In-house production of all components

• Quick delivery and installation

• Professional service and spare parts availability

When you choose our automatic blowing filling capping machine, you gain a long-term partner in packaging innovation.

Conclusion

In today’s beverage manufacturing world, speed, hygiene, and space-saving designs are critical. That’s why more factories are turning to the blowing-filling-capping combi machine. Whether you're producing mineral water, tea drinks, or dairy, Zhangjiagang Micmachinery provides robust solutions like the blowing filling capping machine and combiblock blowing filling capping machine to optimize your production line with confidence.