- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Automated case packers stand at the forefront of modern manufacturing, revolutionizing packaging processes with their efficiency, precision, and adaptability. These machines, often produced by reputable case packer manufacturers, play a crucial role in optimizing production lines, driving productivity, and ensuring consistent product quality. Let's delve into the significance of automated case packers and the importance of selecting reliable case packer manufacturers.

Maximizing Efficiency with Automated Case Packers

Speed and Precision: Automated case packers excel in swiftly and accurately placing products into cases or containers. Operating with precision and consistency, these machines minimize downtime and significantly increase packaging throughput, allowing manufacturers to meet demanding production targets with ease.

Versatility and Flexibility: Built to handle a diverse range of product types, sizes, and packaging formats, automated case packers offer unparalleled versatility. Whether dealing with bottles, cartons, or pouches, these machines can be seamlessly integrated into various production lines, providing manufacturers with the flexibility to adapt to changing market demands.

Labor Savings and Safety: By automating repetitive and labor-intensive packaging tasks, automated case packers reduce the reliance on manual labor. This not only lowers labor costs but also enhances workplace safety by minimizing the risk of injuries associated with manual handling, creating a safer and more efficient working environment.

Selecting Reputable Case Packer Manufacturers

Quality Assurance: Choosing a reputable case packer manufacturer is paramount to ensuring the performance and reliability of the equipment. Established manufacturers adhere to stringent quality standards, producing robust and durable machines capable of withstanding the rigors of continuous operation.

Customization and Support: Leading case packer manufacturers understand the unique requirements of each production facility and offer customized solutions tailored to specific needs. Additionally, they provide comprehensive support services, including installation, training, and ongoing technical assistance, to maximize machine performance and uptime.

Innovation and Technological Advancements: Top case packer manufacturers invest in research and development to incorporate the latest innovations and technological advancements into their machines. By staying at the forefront of industry trends, they ensure that manufacturers have access to cutting-edge equipment equipped with advanced features, enhancing efficiency, and productivity.

Conclusion

Automated case packers play a pivotal role in optimizing packaging efficiency, streamlining production processes, and maintaining product quality in modern manufacturing facilities. By partnering with reputable case packer manufacturers, manufacturers can access high-quality, reliable machines tailored to their specific needs. Investing in automated case packing technology not only enhances operational efficiency but also drives long-term success and competitiveness in today's rapidly evolving market landscape.

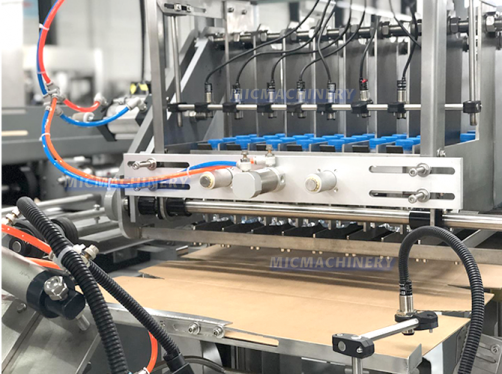

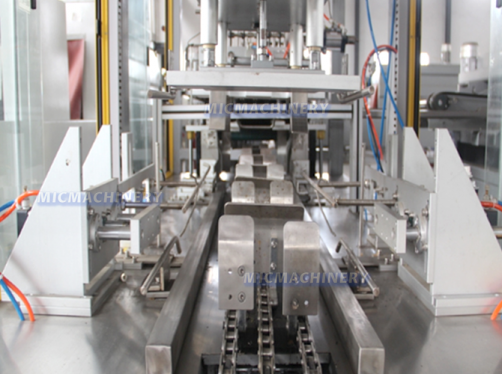

Bottle are separated to multi channel at conveyor, and then group by bottle separate fracture evenly. Bottle are grouped , then drop to cardboard via bottle drop fracture. At drop fracture with bottle and cardboard fall procedure, via one group of form block board, then card board fold to carton form. Via main drive with carton move forward, at the same time, via glue spray fracture to finish carton top glue spray, again the cam fracture via top ledge fold, at the same top carton fold to finish top sticking. Carton move forwarder, again via glue spray fracture to finish carton side glue spray, and via side pressure and carton press fracture to finish carton finally form and sticking, and via main drive let carton move forwarder to conveyor .

◆ Machine Parts

Technical parameter

|

Name |

Case packing machine |

Power supply |

380V,three-phase |

|

Production capacity |

10-14case/ minute |

Power supply |

220V AC |

|

Hot glue solidify time |

≤1.5-2S |

Main machine power |

10KW |

|

weight |

3.5T |

Gas consumption quantity |

1500 L/min |

|

Machine overall size |

6285*2582*2115 |

Compressor air requirement |

0.6~0.8MPa |

|

Bottle enter size |

3000*620*1200 |

Package product overall size |

(350-450) |

|

Cardboard specific requirement |

Material: corrugate, carton indentation thread thickness is moderate, width is not bigger than 2mm |

||

Related collocation description:

|

Name |

Model |

Amount |

Brand |

Original |

|

Miniature circuit breaker |

4P C20 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

1P C10 |

1 |

Schneider |

France |

|

A.C.contactor |

E1810 |

1 |

Schneider |

France |

|

A.C.contactor |

E09104 |

3 |

Schneider |

France |

|

Switching power supply |

S8JC-Z05024C |

1 |

Schneider |

France |

|

PLC |

SIMATIC S7-200 |

1 |

Siemens |

Germany |

|

Touch screen |

SMART 700 IE V3 |

1 |

Siemens |

Germany |

|

Frequency transformer |

SINAMICS V20 |

1 |

Siemens |

Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment