Product Application

1. Diverse Offerings:

Step into a world of creativity with our juice production lines, where crafting beverages goes beyond the ordinary. Whether you're inclined towards the traditional allure of single-fruit juices or seeking innovation through unique blends, our lines provide the versatility to cater to a broad spectrum of consumer preferences.

2. Customizable Solutions:

Adaptability defines our juice filling line. Tailor your manufacturing process to align with market demands, effortlessly accommodating seasonal variations and embracing regional nuances. The inherent flexibility of our solutions empowers you to stay ahead, responding promptly to the ever-changing landscape of consumer preferences and trends.

3. Ready-to-Drink Convenience:

Anticipate and meet the evolving needs of modern consumers with our fruit juice filling production line crafted for the creation of convenient ready-to-drink juices. Seamlessly blending efficiency with quality, our production lines ensure that your on-the-go beverage offerings not only meet but exceed expectations. Embrace the convenience culture while delivering freshness and exceptional taste.

Machine Function

1. Precision Juice Filling:

Delve into the heart of our technology, where our machines excel in the art of precise juice filling. Whether it's a delicate fruit blend or a refreshing single-fruit juice, our machines ensure accurate filling, maintaining the integrity of flavors and textures.

2. Aseptic Processing:

Elevate the quality of your juice products with our aseptic processing capabilities. Our juice filling line are equipped to maintain the freshness and nutritional value of the juices, extending shelf life without compromising on taste or quality.

3. Customizable Configurations:

Tailor the production process to your unique requirements with our customizable configurations. From bottle sizes to filling volumes, our machines offer flexibility, allowing you to create a bespoke solution that aligns perfectly with your juice production goals.

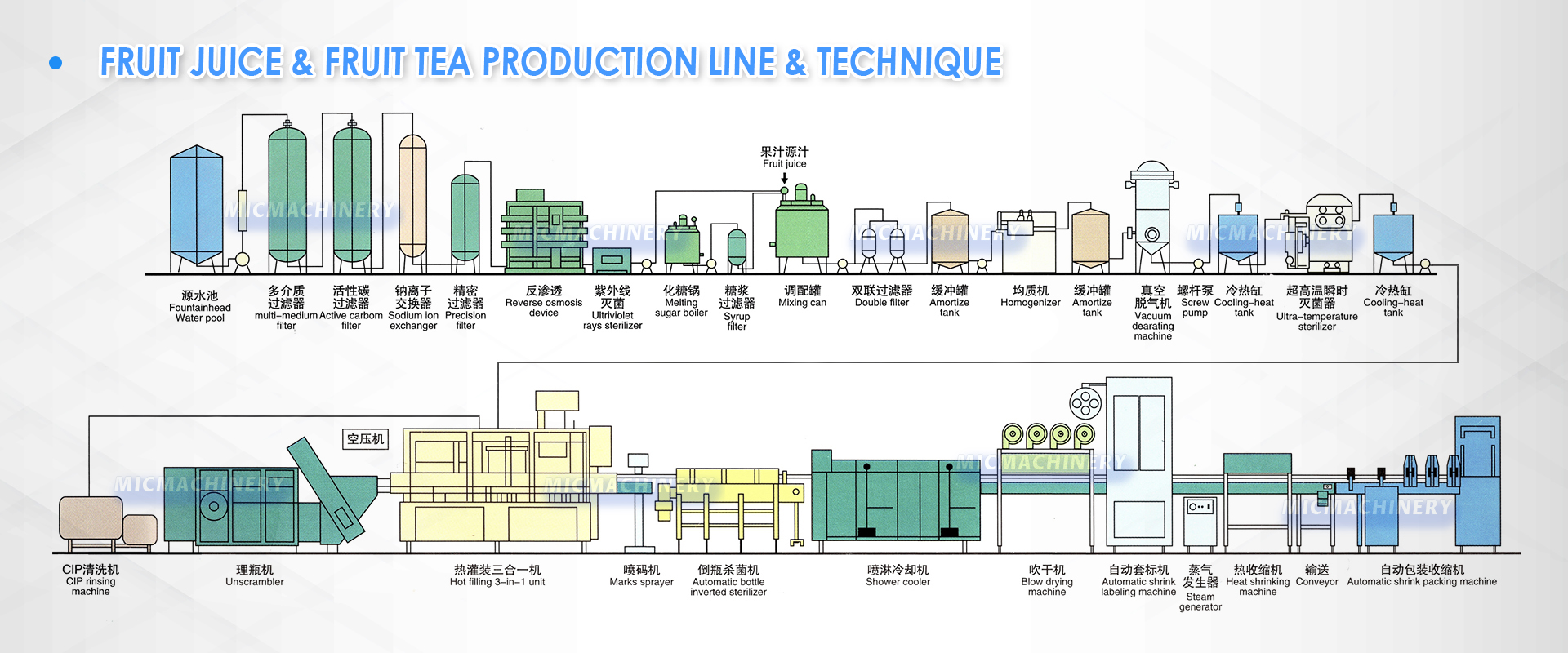

Machine Workflow

1. Efficient Raw Material Handling:

Witness a seamless transition from raw materials to the production line. Our machines are adept at handling various fruit types, ensuring a smooth workflow that minimizes wastage and maximizes efficiency.

2. Automated Processing:

Experience the efficiency of automated processing that defines our juice production lines. From washing and peeling to extraction and blending, each step is meticulously handled by our machines, reducing manual intervention and ensuring consistency.

3. Streamlined Packaging:

Conclude your juice production journey with streamlined packaging. Our machines seamlessly integrate with packaging processes, delivering a final product that not only tastes exceptional but is also presented attractively on the shelves.

Speed: 1000-2000CPH

Speed: 480CPH

Speed: 5000-12000BPH

Speed: 3000-5000BPH

Speed: 5000-12000BPH

Speed: 1800BPH

Juice Production Line: A Symphony of Technology and Flavor

1. Dynamic Juice Production Line:

• At the nucleus of Mic Machinery's offerings lies the dynamic juice production line. This system seamlessly blends technology and flavor to craft juices that captivate the taste buds. From initial processing to final packaging, every step is optimized for efficiency and quality.

• Automated Processing Systems: Our juice production line incorporates automated processing systems that precisely extract and blend juices. This not only ensures consistency in flavor but also retains the nutritional integrity of the fruits.

• Packaging Precision: The line's packaging systems guarantee precision, with automated filling and capping mechanisms. Each bottle that emerges from our production line is a testament to the commitment to excellence in juice packaging.

2. Juice Filling Line: Precision in Every Pour

• The juice filling line is where precision takes center stage. Mic Machinery leverages advanced technology to provide a filling process that guarantees quality in every pour.

• Consistent Fill Levels: Automated systems maintain a consistent fill level in every bottle, meeting the highest quality standards and ensuring a delightful drinking experience for consumers.

• Adaptive Configurations: Flexibility is key in our filling line. It adapts seamlessly to various bottle sizes and types, accommodating a diverse range of products and packaging preferences.

• Efficient Capping Systems: The line features automated capping mechanisms that contribute to the overall freshness and quality of the final product. Secure seals are ensured, preserving the flavor and extending the shelf life of the juices.

3. Fruit Juice Filling Production Line: Versatility in Every Sip

• Mic Machinery's fruit juice filling production line is engineered for versatility and efficiency, offering a canvas for producers to create an array of captivating fruit juice blends.

• Multifruit Blending Capability: The line accommodates a wide range of fruit varieties, allowing for the production of diverse fruit juice blends. Producers can experiment with unique combinations or stick to traditional favorites.

• Automated Mixing Systems: Precision-controlled mixing ensures uniform flavor distribution, enhancing the quality and consistency of every fruit juice blend that emerges from our production line.

• Seamless Packaging: Efficient packaging systems ensure that each bottle of fruit juice reaches consumers with freshness intact. The line is designed to handle a variety of packaging options, from traditional bottles to innovative containers.

Technological Ingenuity: Crafting Quality in Every Bottle

1. Automated Filling Systems:

Mic Machinery's juice production lines feature state-of-the-art automated filling systems. This technological marvel ensures precise control over fill levels, minimizing variations and contributing to a final product of unparalleled quality.

2. Adaptive Bottle Handling:

The machines in our lines feature adaptive bottle handling systems, ensuring a seamless transition from initial placement to final packaging. This adaptability minimizes downtime and maximizes production output, irrespective of bottle size or type.

Ease of operation is paramount in our design philosophy. Mic Machinery's juice production lines boast user-friendly interfaces, empowering your production team to operate at peak efficiency with minimal training and downtime.

Adaptability to Diverse Juice Types: Meeting Industry Demands

1. Versatile Juice Production:

Tailored for the diverse juice market, our production line accommodates a wide range of juice types, from citrus to tropical blends. The line's versatility positions Mic Machinery as a trusted partner for juice producers seeking excellence in every bottle.

The fruit juice filling production line is engineered for versatility, allowing producers to create specialized fruit juice blends. Whether crafting unique combinations or traditional favorites, our line adapts to the varied demands of the market.

In conclusion, Mic Machinery stands as a beacon of excellence, shaping the future of juice production with innovative solutions. Join us at Mic Machinery, where every drop is a testament to precision, versatility, and excellence in the art of juice production. Explore the possibilities with Mic Machinery, your trusted partner in crafting solutions that redefine the landscape of the juice industry.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment