Machine Parameters

1. Customizable Production Capacities:

The machine parameters of drinking water filling machines are characterized by customizable production capacities. Businesses can fine-tune these parameters to meet specific production needs, whether operating on a large scale or a more moderate output. This adaptability ensures that the machine aligns seamlessly with diverse production requirements.

2. Adjustable Filling Precision:

A critical parameter lies in the adjustable filling precision of drinking water filling machines. The technology allows for fine-tuning the filling levels based on bottle sizes, product variations, and quality standards. This adjustable parameter ensures that each bottle is filled with exactness, contributing to a consistently high-quality end product.

3. Efficient Speed Control:

Drinking water filling machines offer efficient speed control as a paramount parameter. The adjustable speed feature enables businesses to optimize the filling process according to production goals. This ensures not only precision in every bottle but also overall operational efficiency without compromising quality.

Product Application

1. Versatility in Bottled Water Offerings:

Drinking water filling machines find versatile applications in the production of bottled water. Whether filling still water, sparkling beverages, or enhanced mineral water, these machines adapt seamlessly to a spectrum of product variations. The ability to cater to diverse applications positions them as pivotal components for businesses seeking versatility in their bottled water offerings.

2. Efficient Handling of Different Bottle Sizes:

The application of drinking water filling machines extends to the efficient handling of different bottle sizes. This characteristic is pivotal for businesses catering to varying consumer preferences and packaging requirements. The adaptability in size ensures that each bottle, regardless of dimensions, is filled with meticulous accuracy.

3. Precision in Mineral Water Bottling:

Drinking water filling machines showcase precision in mineral water bottling, emphasizing the importance of purity and quality. The adjustable parameters allow for the customization of the filling process, ensuring that mineral water bottles maintain consistent liquid levels. This precision aligns with the discerning standards of modern consumers in the bottled water market.

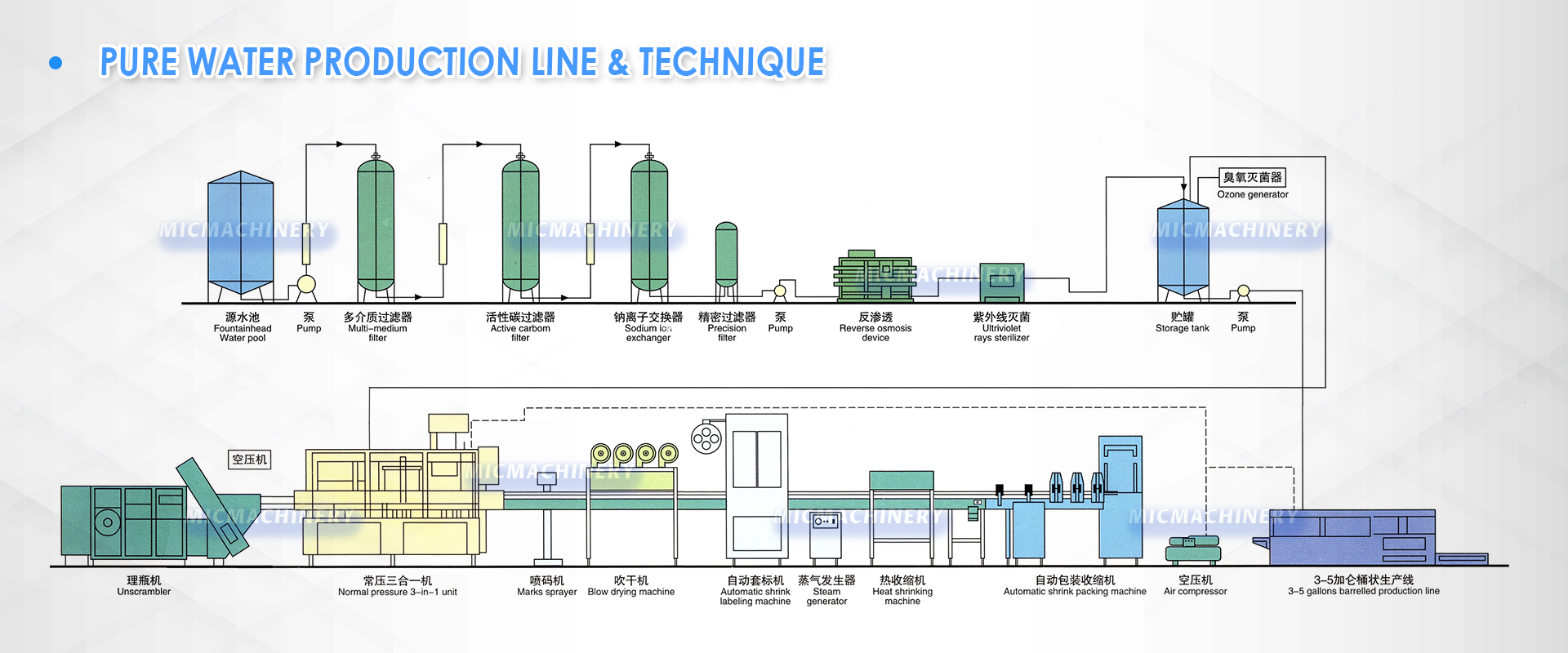

Machine Workflow

1. Efficient Bottle Conveyance and Sterilization:

The workflow of drinking water filling machines begins with efficient bottle conveyance and sterilization. Advanced systems ensure the seamless movement of bottles through the production line, accompanied by a thorough sterilization process. This initial phase sets the stage for the creation of high-quality bottled water.

2. Precision Filling Mechanism:

The heart of the workflow lies in the precision filling mechanism of drinking water filling machines. These systems ensure accurate liquid levels in each bottle, maintaining consistency and meeting the highest quality standards. The integration of gravity and pressure-based mechanisms contributes to the overall efficiency of the production line.

3. Automated Capping and Packaging:

Following filling, the workflow seamlessly transitions to automated capping and packaging stages. Automated capping mechanisms secure an airtight seal, preserving the freshness and purity of the water. The final step involves the systematic packaging of bottles, readying them for distribution while maintaining the integrity of the product. This automated workflow ensures market-ready products with minimal manual intervention.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

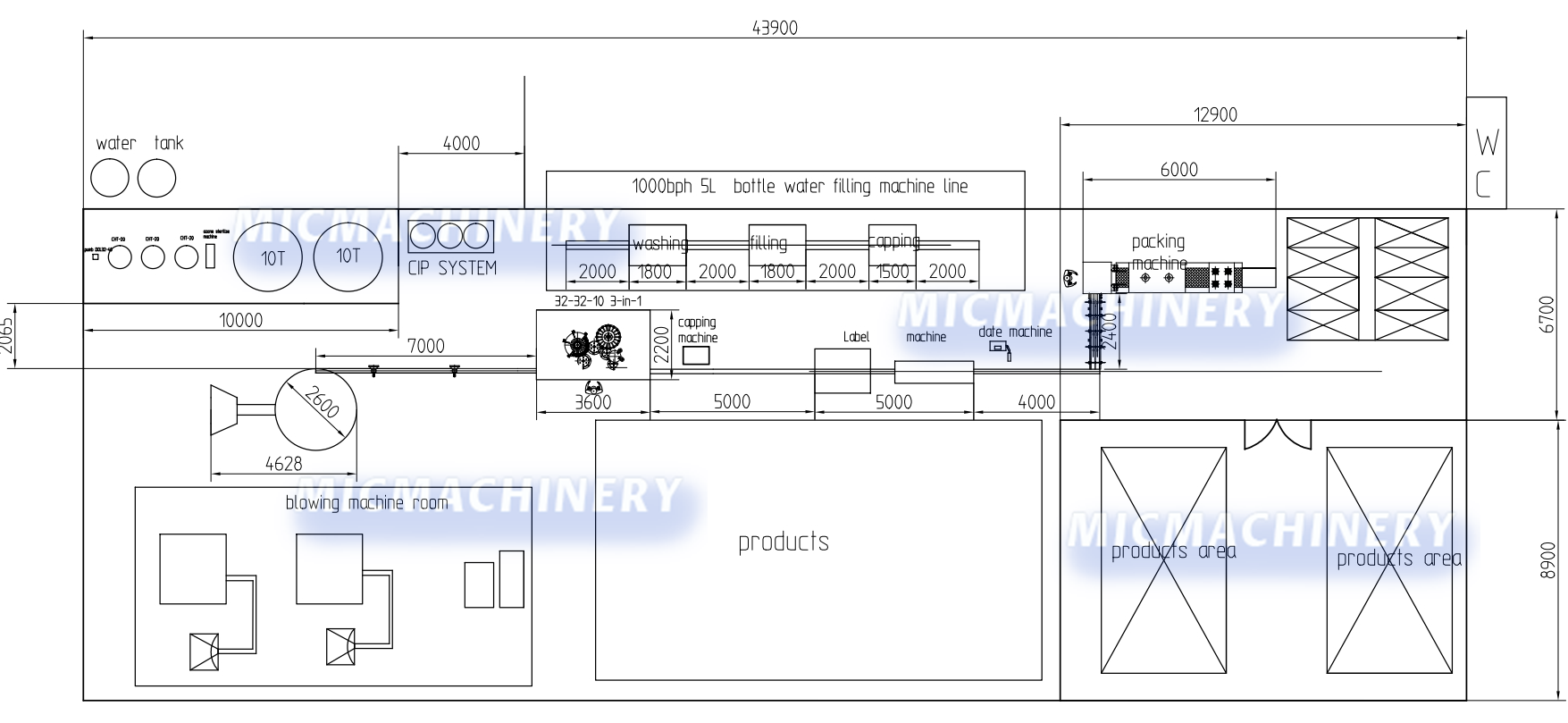

Drinking Water Filling Machine:

At Mic Machinery, our commitment to excellence is embodied in our technologically advanced drinking water filling machines. Engineered for precision and efficiency, these machines seamlessly handle every aspect of the bottling process, ensuring optimal quality from water purification and treatment to precise filling, capping, labeling, and packaging. Our machines are adaptable to various production scales, providing efficiency for both large-scale enterprises and smaller operations.

Water Bottle Packing Plant Price:

Discover cost-effective solutions with our innovative water bottle packing plant. Mic Machinery believes in making advanced technology accessible to businesses of all sizes. Our packing plant offers efficiency without compromising quality, providing an ideal solution for businesses looking to enter or expand their presence in the water bottling industry at an affordable price.

Mineral Water Bottle Machine Price:

Explore competitive pricing with our specialized mineral water bottle machines. Mic Machinery understands the diverse needs of the market and offers transparent pricing, making advanced technology accessible without straining your budget. Our mineral water bottle machines are designed to cater to businesses seeking quality and efficiency in the production of mineral water.

Key Features of Mic Machinery's Drinking Water Filling Machines:

1. Precision and Efficiency:

Our drinking water filling machines ensure precision at every stage, from filling to capping, minimizing wastage and maximizing output efficiency.

2. Adaptability:

These machines are adaptable to various production scales, providing efficiency for both large-scale enterprises and smaller operations.

3. Cost-Effective Packing Plant:

Our water bottle packing plant offers a cost-effective solution for businesses entering or expanding in the water bottling industry.

4. Transparent Pricing:

Mic Machinery offers competitive and transparent pricing, ensuring that businesses of all sizes can benefit from advanced technology without compromising their budget.

Why Choose Mic Machinery:

1. Innovation and Technology:

Stay ahead of industry trends with Mic Machinery, where our commitment to innovation ensures that your operations remain cutting-edge.

2. Quality Assurance:

Our equipment is engineered with precision and reliability in mind, guaranteeing that your water bottling operations consistently meet and exceed industry quality standards.

3. Transparent Pricing:

Mic Machinery offers competitive and transparent pricing, making advanced technology accessible without compromising your budget.

Elevate your water bottling operations with Mic Machinery's state-of-the-art drinking water filling machines. Explore our range, experience unmatched quality, and position your brand as a leader in the dynamic water bottling industry.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment