Machine Function

1. Automated Filling Operations:

• Streamlined Production: Beverage Bottling Machines are designed to automate the intricate process of filling bottles with precision and speed, minimizing manual labor and maximizing efficiency.

• Consistent Filling Levels: These machines ensure uniformity in product quality by precisely controlling the filling levels, eliminating variations across batches.

2. Versatile Packaging Functions:

• End-to-End Solutions: Beverage Packaging Equipment goes beyond filling, incorporating functions such as capping, labeling, and packaging. This comprehensive approach offers a one-stop solution for your entire production line.

• Customizable Configurations: Adapt the machine to your specific needs with customizable settings, allowing you to package various beverage types, including soft drinks, with ease.

Machine Application

1. Beverage Packaging Equipment for Diverse Products:

Versatility is a key strength of these machines, accommodating a wide array of beverages, including soft drinks, carbonated beverages, juices, and more. This adaptability allows beverage manufacturers to diversify their product lines without the need for extensive reconfiguration.

2. Customizable Configurations:

Beverage Bottling Machines come in various configurations, catering to the specific needs of different production scales. From compact models suitable for small-scale operations to high-speed, fully automated systems for large-scale facilities, there's a machine to match every requirement.

3. Bottle Size and Material Compatibility:

These machines are designed to handle various bottle sizes and materials, providing flexibility in packaging options. Whether you choose PET bottles, glass containers, or other materials, the equipment can be adjusted to suit your preferences and sustainability goals.

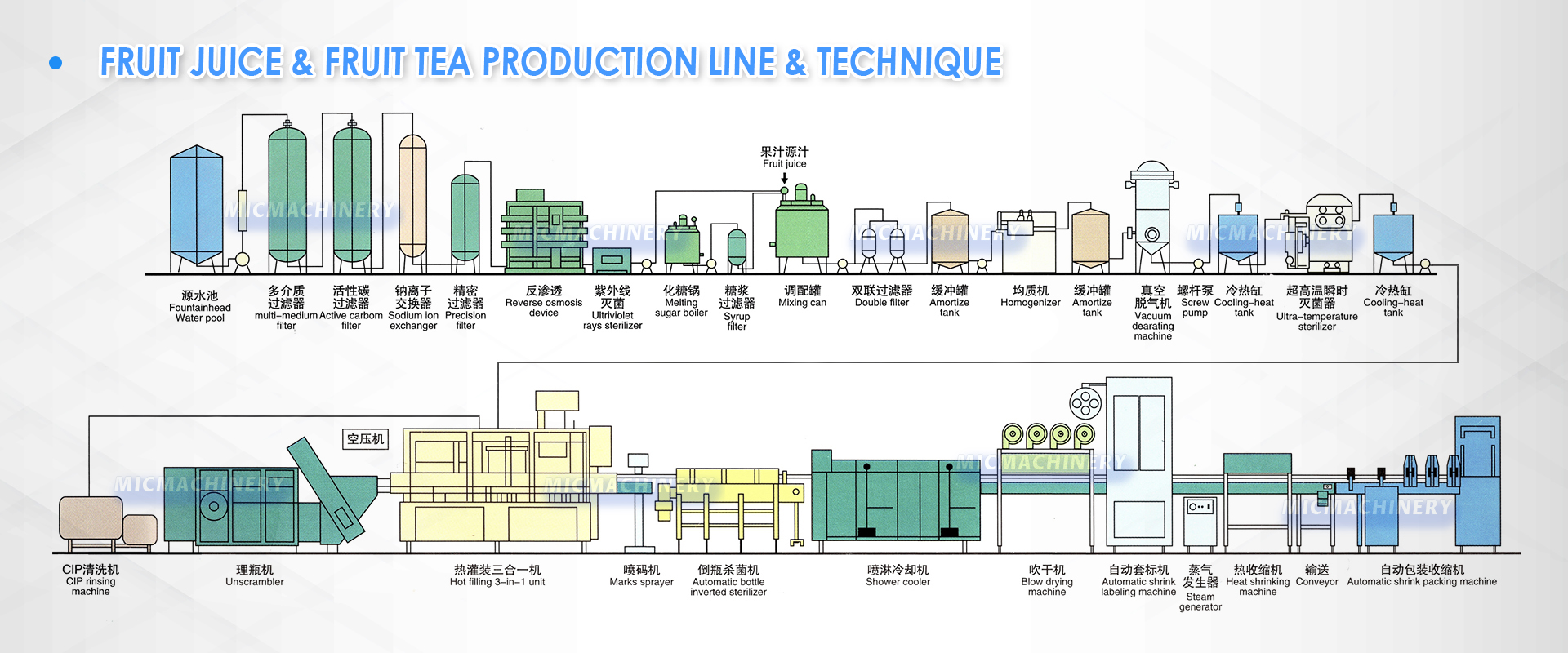

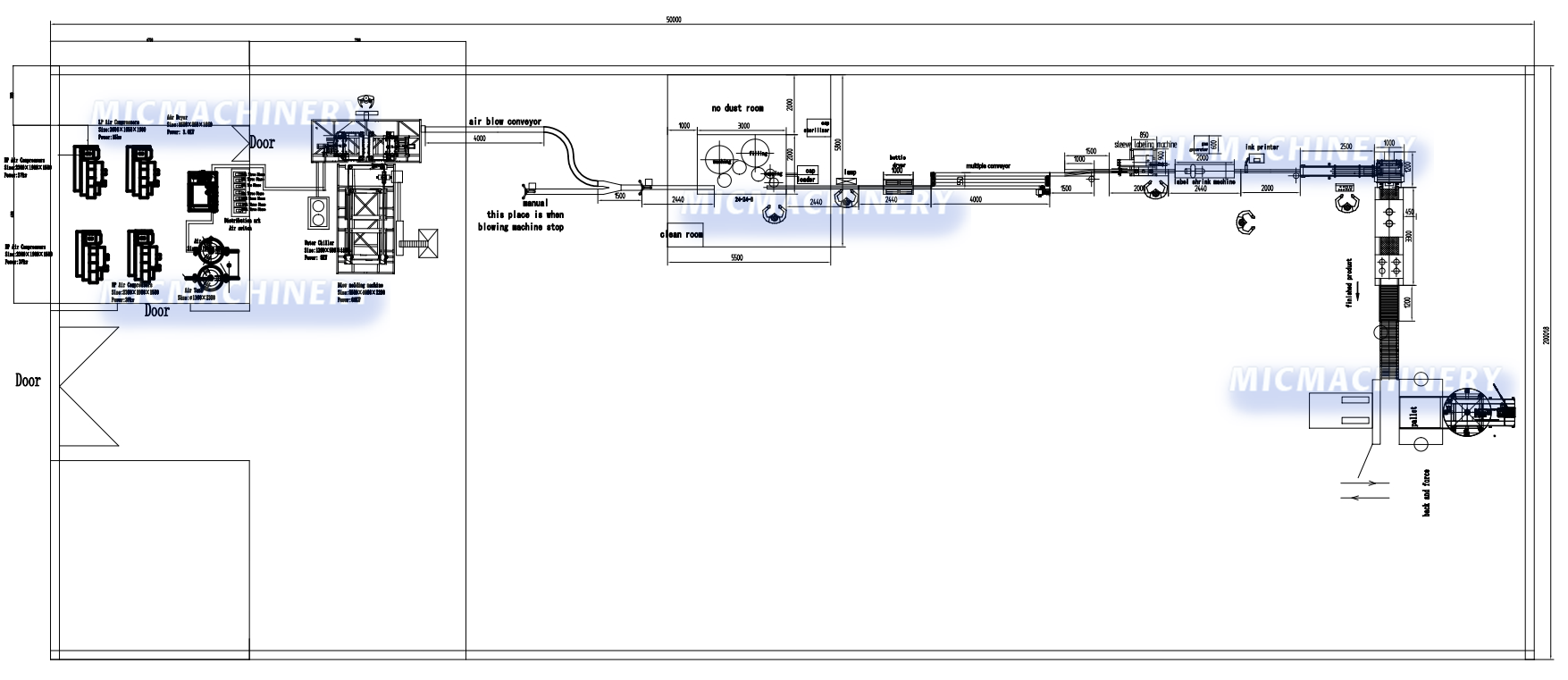

Technical Principle

1. Advanced Liquid Filling Systems:

Leveraging state-of-the-art technology, Beverage Bottling Machines utilize advanced liquid filling systems, including gravity filling, pressure filling, or vacuum filling. These systems ensure precise liquid levels and minimize spillage, contributing to overall efficiency.

2. Capping and Sealing Mechanisms:

The sealing process is executed with precision, employing high-quality components for secure and tamper-evident closures. This not only preserves the beverage's integrity but also enhances consumer confidence in the product.

3. Smart Automation:

These machines operate with intelligent automation, optimizing the entire bottling process. From liquid filling to capping and labeling, automation reduces the risk of errors, increases production speed, and ensures a streamlined and reliable packaging process.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Beverage Packaging Equipment:

At Mic Machinery, we offer a comprehensive range of beverage packaging equipment designed to cater to diverse industry needs. Our machines are crafted with the latest technological advancements, ensuring precise and consistent performance. From filling to sealing and labeling, our equipment is engineered to handle every stage of the packaging process with finesse. Whether you're bottling carbonated soft drinks, still beverages, or specialized products, our packaging solutions are tailored to maintain the integrity and freshness of your products.

Soft Drink Packaging Machines:

Our specialized soft drink packaging machines are at the forefront of beverage technology. Engineered to handle the intricacies of carbonated beverages, these machines ensure the preservation of effervescence and flavor. Advanced carbonation control and sealing mechanisms guarantee that every soft drink bottle leaving our machines maintains its freshness, enticing consumers with a delightful drinking experience. With intuitive interfaces and precise automation, our soft drink packaging machines offer unmatched reliability, ensuring consistent product quality batch after batch.

Versatile Beverage Bottling Machines:

Our beverage bottling machines are versatile workhorses, designed to adapt to various beverage types and packaging requirements. These machines accommodate different bottle shapes, sizes, and materials, providing flexibility for businesses of all scales. Equipped with advanced sensors and controls, our bottling machines maintain accurate filling volumes, minimize wastage, and maximize production efficiency. Whether you're bottling large quantities of soft drinks or limited editions of specialty beverages, our machines guarantee unmatched precision and reliability.

At Mic Machinery, we don't just provide machinery; we offer solutions that empower your business to thrive in the competitive beverage market. Our dedication to quality, innovation, and customer satisfaction sets us apart. When you choose our soft drink packaging machines and beverage bottling machines, you're investing in a partnership that ensures the success of your products. Join us in shaping the future of beverage packaging, where excellence is not just a goal but a guarantee.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Aseptic filling machine

- Laser batch coding machine

- Affordable Beverage Processing Solutions

- Fruit And Vegetable Processing Line

- Industrial Milk Processing Plant

- Alcoholic Drink Production Machinery

- Commercial Water Treatment System

- Combiblock Blowing Filling Capping Machine

- Bone Broth Osteoin Bone Peptide Production Line

- Biological Fermentation Engineering

- Extractive Beverage Processing Production Line

- Tomato Carrot Vegetable Processing Line

- Citrus Fruit Processing Line

- Apple Pear Fruit Processing Line

- Mango Fruit Processing Line

- Peach Apricot Plum Fruit Processing Line

- Date jujube hawthorn fruit processing line

- Plant protein drinks processing line

- Tea beverage production line

- Rear packaging production line

- Circulating Bottled Water Production Line

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment