- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

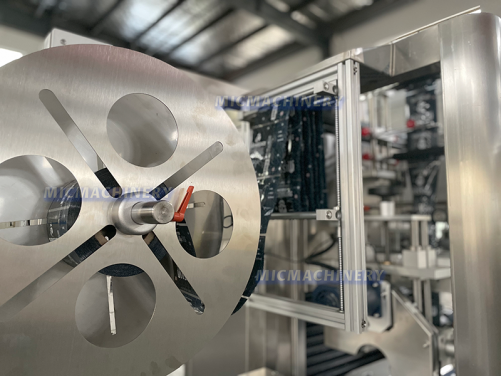

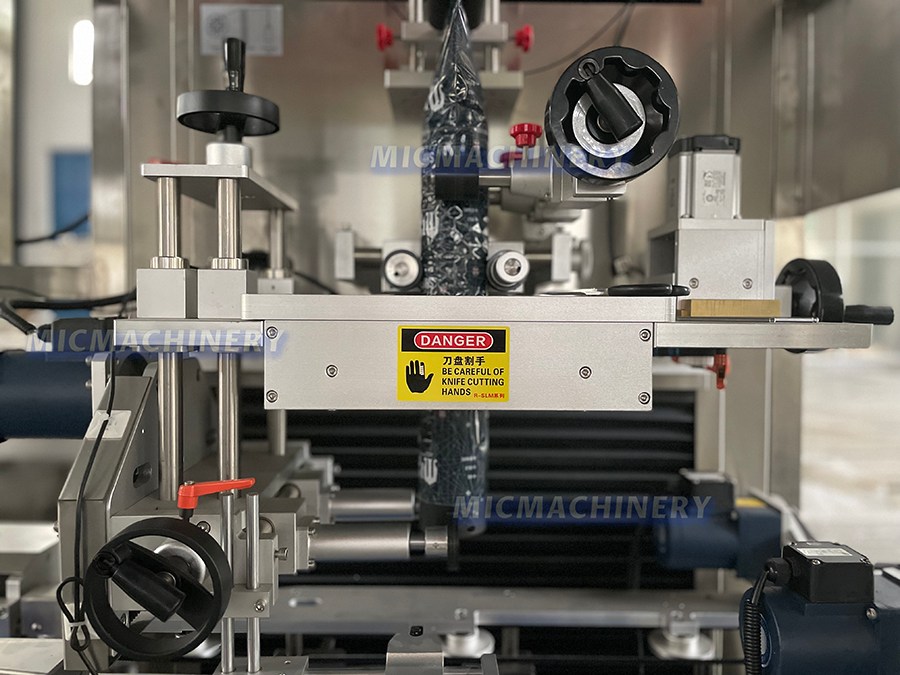

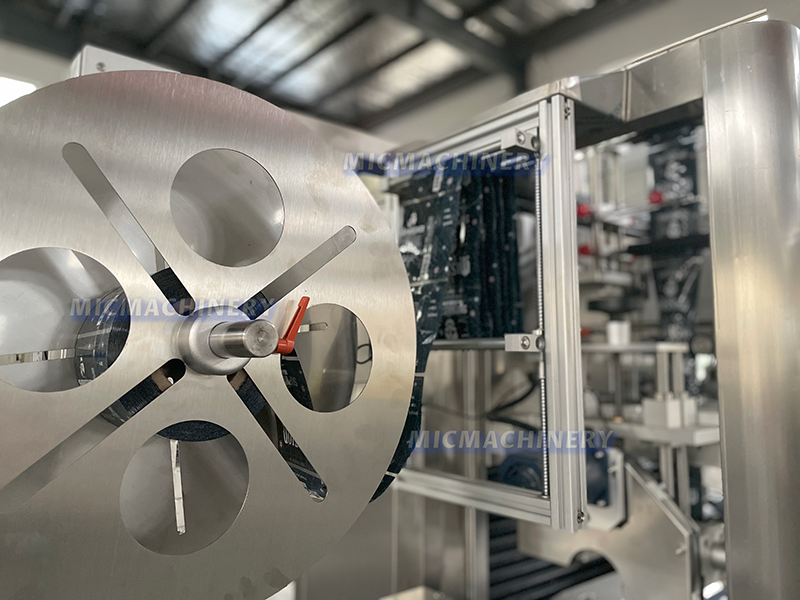

Sleeving machines are designed for packaging and labeling products such as bottles, cans, and jars with a variety of sleeve labels, including shrink sleeves and stretch sleeves. These machines are widely used in the food and beverage, pharmaceutical, and cosmetic industries to improve the appearance of products and enhance brand identity. Here are some key features and benefits of sleeving machines:

1. Versatility: Sleeving machines can handle a wide range of products and sleeve label types, making them a versatile choice for manufacturers.

2. High Speeds: These machines are capable of labeling products at high speeds, reducing labor costs and increasing production efficiency.

3. Accurate Label Placement: With precise label placement technology, sleeving machines ensure that labels are applied accurately and consistently, resulting in a professional-looking product.

4. Easy to Operate: Modern sleeving machines are designed to be user-friendly and easy to operate, allowing for quick and easy changeovers between products and label types.

5. Space-Saving Design: Many sleeving machines have a compact design, making them ideal for manufacturers with limited space.

6. Improved Product Protection: Sleeve labels can provide additional protection to products, such as tamper-evident seals, which can help prevent product contamination and ensure consumer safety.

Overall, sleeving machines provide a cost-effective, efficient, and reliable solution for packaging and labeling products, helping manufacturers to improve their brand image and meet consumer demand.

Sleeving machines can handle various sizes and shapes of products, making them highly versatile in the packaging process. They can apply full-body sleeves or partial sleeves, depending on the product's requirements. The machines are equipped with advanced automation systems that can handle high-speed production, reducing labor costs and increasing production efficiency.

Sleeving machines are also designed to ensure product safety and quality, providing tamper-evident solutions that prevent contamination and protect product integrity. The tamper-evident bands can easily be removed by consumers, indicating that the product has not been opened or tampered with.

Investing in a sleeving machine can provide numerous benefits to the packaging process, including increased production capacity, improved product quality, reduced labor costs, and enhanced product safety and security. Additionally, the use of sleeving machines can help reduce the environmental impact of the packaging process, such as waste and energy consumption.

|

Input power |

1.5KW |

|

Input voltage |

3380/220VAC |

|

Productivity |

Maximum 50 bottles/min (bottles/min) |

|

Host size |

2000Lx850Wx2000H |

|

Applicable bottle diameter |

50mm ~ 96mm |

|

Applicable label height |

30mm ~ 150mm |

|

Applicable label thickness |

0.03mm ~ 0.13mm |

|

Applicable inner diameter of paper tube |

5"~ 10" freely adjustable |

|

Name |

Amount |

Unit |

Brand |

|

PLC |

1 |

Tower |

Siemens |

|

Touch screen |

1 |

Tower |

Siemens |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

2 |

Tower |

Panasonic |

|

Servo motor for label delivery |

1 |

Tower |

Panasonic |

|

Servo drive for label delivery |

1 |

Tower |

Panasonic |

|

Cutter servo Motor |

1 |

Tower |

Panasonic |

|

Cutter Servo Drive |

1 |

Tower |

Panasonic |

|

Bottle divider |

1 |

Tower |

Panasonic |

|

Inverter with bottle |

1 |

Tower |

Panasonic |

|

Rack inverter |

1 | Tower |

Panasonic |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment