- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Manual Beer Can Filler Machine is applicable for beer, (Cold filling temperature at 0-4 degrees Celsius)

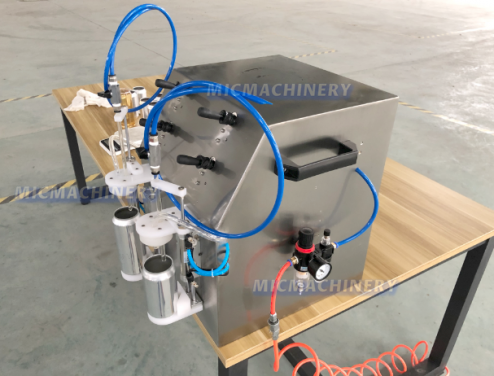

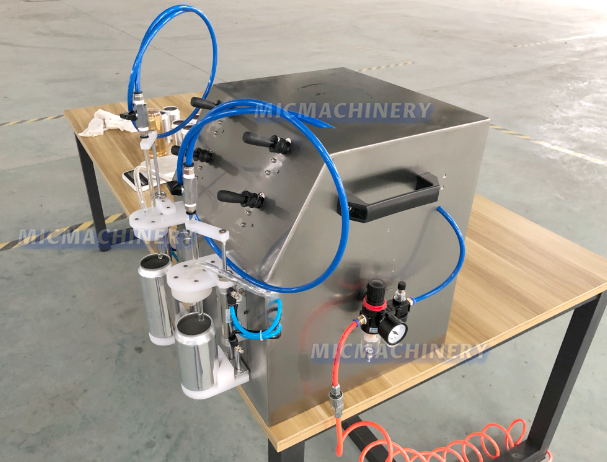

Introducing the MIC Manual Beer Can Filler Machine, an essential addition to any brewery aiming to enhance its beer can packaging process. Designed for efficiency and ease of use, this beer can filling machine allows operators to fill up to 8 cans per minute, making it an ideal choice for small to medium-sized breweries looking to streamline their operations.

Key Features:

1. High Efficiency: Capable of filling 8 cans per minute, our beer can filler machine maximizes productivity without compromising on quality. This efficient filling rate ensures that your production line runs smoothly and keeps up with demand.

2. Manual Operation: The user-friendly design of the MIC Manual Beer Can Filler Machine allows for simple manual operation. This feature not only reduces training time for staff but also minimizes the risk of operational errors, ensuring that your beer can packaging process is consistent and reliable.

3. Precision Filling: Equipped with advanced filling technology, this beer can packaging machine ensures precise filling levels with minimal foam. This is crucial for maintaining the quality and taste of your beer, while also reducing waste and maximizing product yield.

4. Robust Construction: Built with high-quality materials, the MIC Manual Beer Can Filler Machine is designed for durability and longevity. Its sturdy construction ensures that it can withstand the rigors of a busy brewery environment, providing reliable performance over time.

5. Compact Design: The compact design of this machine allows it to fit into various workspace configurations without occupying excessive space. This makes it an ideal choice for breweries with limited floor space.

6. Easy Maintenance: Designed with user convenience in mind, the MIC Manual Beer Can Filler Machine features easy access for maintenance and cleaning. This ensures that your equipment remains in optimal condition, enhancing its longevity and performance.

7. Versatile Applications: Suitable for a variety of canned beverages, this beer can filler machine can accommodate different can sizes and types, making it a versatile tool in your production line.

8. Affordable Investment: Offering high-quality features at a competitive price point, the MIC Manual Beer Can Filler Machine provides excellent value for breweries looking to enhance their beer can packaging capabilities without a significant financial investment.

At Micmachinery, we are committed to providing top-tier machinery that meets the unique needs of our clients. The MIC Manual Beer Can Filler Machine exemplifies our dedication to quality and efficiency in the brewing industry. By investing in our beer can packaging machine, you are not only enhancing your production capabilities but also ensuring the integrity and quality of your craft beer.

Control Button

Control buttons can control when the machine starts filling and can stop filling manually.

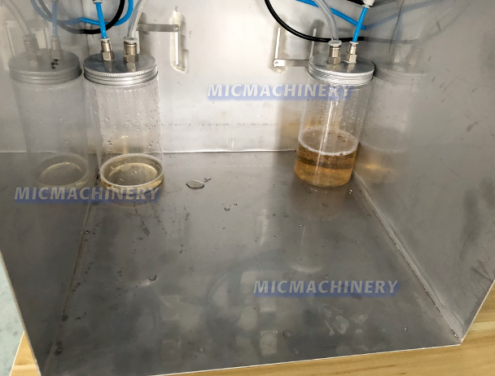

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment