- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Key Features and Advantages

-

Optimized Speed Range: With a speed range of 200-800BPH, the Semi Automatic Small Scale Beer Bottling Equipment offers an adaptable filling solution for breweries of varying production volumes.

-

-

Precision and Consistency: The beer bottle filler is designed to fill bottles with high precision, ensuring that each bottle receives the exact amount of beer without overflows or underfills. This consistency improves the overall quality control of your beer and reduces product wastage.

-

-

Glass Bottle Compatibility: This machine is specifically engineered for glass beer bottles, making it the ideal solution for breweries that package their beer in glass bottles. The machine can handle a variety of bottle sizes, providing flexibility in packaging options.

-

-

Hygienic and Easy to Clean: Constructed from high-quality, food-grade materials such as SS304, the beer bottle filler ensures a hygienic filling environment. It’s easy to clean, which is crucial in maintaining the integrity and flavor of the beer throughout the bottling process.

-

-

User-Friendly Operation: The semi-automatic design makes this equipment easy for operators to use. Bottle loading and unloading are done manually, while the machine handles the filling process. The straightforward operation minimizes training time and enhances production efficiency.

-

-

Low Maintenance Costs: The simple design of the Semi Automatic Small Scale Beer Bottling Equipment results in fewer parts and less complex maintenance. With low maintenance costs, this machine offers a great return on investment for small to medium-sized breweries.

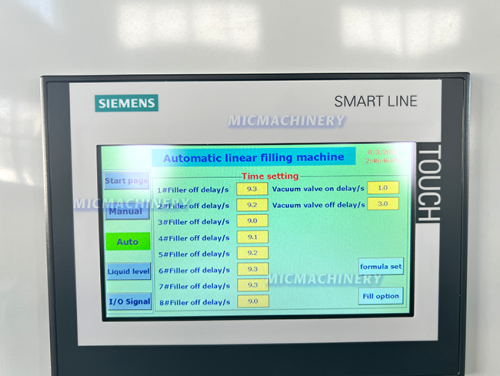

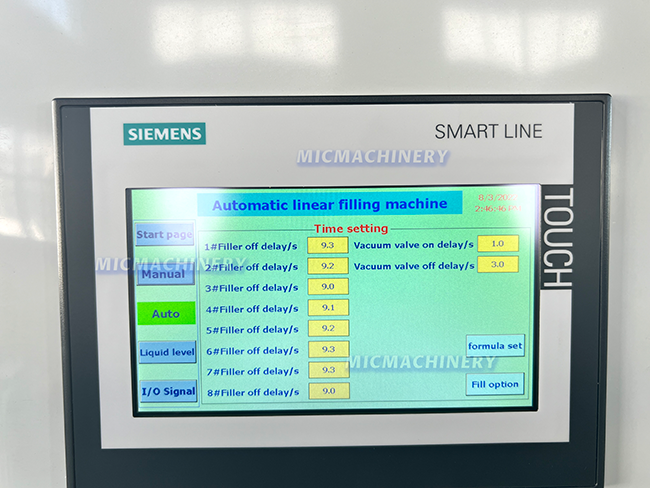

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

|

|

Name |

Brand |

|

1 |

Push Button |

Schneider France |

|

2 |

Electromagnetic Contactor |

Schneider France |

|

3 |

Relays |

Omron Japan |

|

4 |

Frequency Converter |

Siemens |

|

5 |

Air Cylinder |

AirTAC Taiwan |

|

6 |

Electromagnetic Valve |

AirTAC Taiwan |

|

7 |

PLC Control System |

Siemens |

|

8 |

Touch Screen |

Siemens |

|

9 |

Photoelectric Switch |

Autonics |

|

10 |

Proximity Switch |

Autonics |

|

11 |

Reducer |

Zhejiang Duoli China |

|

12 |

Sealing Motor |

Zhejiang Duoli China |

|

13 |

Barometer |

AirTAC Taiwan |

|

14 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment