- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

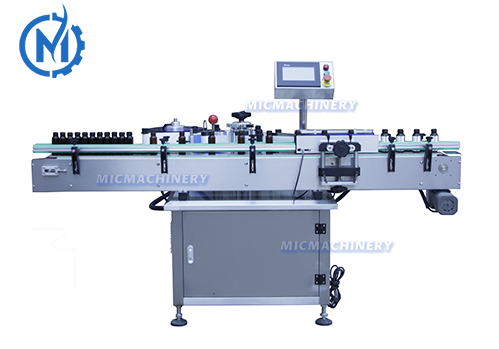

Rxl-a vertical round bottle sticker labeling machine designed to achieve reasonable production objectives.Labeling process is automated, simple operation, fast production speed, labeling position is unified, beautiful, neat;Suitable for circular container labeling in pharmaceutical, chemical and food industries.

2. Working principle:

After the bottles enter the conveyor belt of the labeling machine, they are fed to the labeling machine at a constant speed. The fixed device on the machine separates the stickers from each other at a fixed distance and pushes the stickers along the direction of the conveyor belt.Through the mechanical system (drive wheel, label wheel, reel) drive wheel intermittently drag the label belt movement, the label from the reel, through the label device on the paste.

3. Product features:

◆ wide range of application, can meet the full circle labeling or half circle labeling round bottles, easy to switch labeling between bottles, easy to adjust;◆ high labeling accuracy, subdivided stepper motor or servo motor drive feed, feed accurate;The design of belt winding rectifying mechanism ensures that the label does not deviate from left to right in the process of traction;Eccentric wheel technology is applied to traction mechanism, traction label does not slip, to ensure accurate marking;

◆ solid and durable, adopt three-bar adjusting mechanism, make full use of triangle stability, the whole machine is solid and durable;

◆ high stability, Siemens PLC, Siemens touch screen, panasonic servo motor composed of advanced electronic control system, support equipment 7×24 hours of operation;

◆ flexible application, single production or assembly line production, simple production site layout;

◆ intelligent control, automatic photoelectric tracking, with no marking, no marking automatic correction and automatic label detection function, to prevent the leakage and label waste;

◆ touch screen operation interface, full Chinese comments and perfect fault prompt function, easy and quick adjustment of various parameters, easy to operate;

◆ powerful function, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

◆ optional functions:

※ the function of hot typing code/spraying code;

* automatic feeding function (considering the product);

* automatic material receiving function (considering the product);

※ adding labeling device;

※ other functions (customized according to customer requirements).

|

Voltage specification |

AC220V 50/60HZ |

|

power consumption |

1.0KW |

|

Labeling speed |

50-120 vials/min (speed adjustable, depending on object size and label length) |

|

Labeling accuracy |

+1mm (depending on product characteristics, hardness and roundness) |

|

Bottle diameter |

25-120mm |

|

Height |

20mm ~ 300mm (can be customized according to customer requirements) |

|

Label |

height 10mm ~ ~ 150mm length 15 ~ ~ 300mm (special specification can be customized) |

|

Paper roll diameter |

Φ paper roll diameter: 76 mm Φ 300 (maximum) |

|

Weight |

200KG |

|

Package size |

2000X800X1300mm |

|

Conveyor belt width |

can be customized according to the diameter of the sample bottle provided |

|

Part name |

nameplate |

|

Label step motor |

joint venture |

|

Label the motor drive |

|

|

Conveyor belt motor |

Intensive research (sino-german joint venture) |

|

Conveyor belt motor gear box |

|

|

volume of the motor |

|

|

Roll label motor gear box |

|

|

Dividing the motor |

|

|

Split bottle motor gear box |

|

|

Labeling photoelectric |

Keenes, Japan |

|

Transparent label detects photoelectric |

|

|

Programmable controller |

Siemens (Germany) |

|

Man-machine interface |

Siemens (Germany) |

|

Inverter |

Siemens (Germany) |

|

Conveyor belt |

shanghai |

|

Synchronous toothed belt |

Samsung (Japan) |

|

Code printer |

Pneumatic (rui xiao) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment