- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Mic 12-1 coffee juice can filling seaming machine adopts normal pressure filling system which is applicable for fruit juice, cold brew coffee, energy drink, herbal tea, alcoholic beverages and other canned non-carbonated drinks (Cold filling temperature at 0-4 degrees Celsius or hot filling temperature at 80-85 degrees Celsius.)

Mic 12-1 cold coffee juice can filling machine is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and seaming part is the overall designed, in order to ensure that both the absolute synchronization and coordination.

It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small beverage plant.

5. About machine automation, we are able to do what client required.

6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out.

7. Consider of product various ability, we are able to make machine for replace air from the can package.

At Micmachinery, we are committed to delivering innovative solutions tailored to meet the diverse needs of the beverage industry. The MIC 12-1 Juice Filling Machine is a compact yet highly efficient system designed to produce 1,000 to 2,000 bottles per hour (BPH), making it an ideal choice for small to medium-sized juice production facilities.

Key Features of the MIC 12-1 Juice Filling Machine

1. High-Precision Filling Technology

The MIC 12-1 is equipped with advanced filling technology to ensure every bottle is filled with precision and consistency. This juice filling machine minimizes product waste, reduces spillage, and guarantees that every bottle meets the exact volume specifications required for quality assurance.

2. Compact and Versatile Design

Engineered to fit into production spaces of various sizes, this juice bottle filling machine offers versatility without compromising performance. Its compact design allows it to integrate seamlessly into existing production lines while maintaining high operational efficiency.

3. Integrated Rinsing, Filling, and Capping Functions

This all-in-one system streamlines the production process by combining rinsing, filling, and capping in a single machine. By reducing the need for multiple pieces of equipment, this juice bottling machine saves space and operational costs while ensuring smooth, continuous production.

4. Hygienic and Food-Grade Construction

The juice bottle filling machine is constructed from high-quality stainless steel that meets international food safety standards. Its design prioritizes hygiene and makes cleaning and maintenance straightforward, helping producers maintain the highest levels of cleanliness in their production facilities.

5. Easy Operation and Adjustment

With an intuitive control panel, operators can easily manage the machine's functions and adjust settings to accommodate different bottle sizes or juice types. This user-friendly feature makes the MIC 12-1 a practical choice for both experienced operators and those new to automated bottling systems.

6. Energy-Efficient Performance

Energy efficiency is critical for modern production lines, and the MIC 12-1 excels in this area. Its energy-saving motor and optimized operational design reduce power consumption, contributing to lower operating costs over time.

Why Choose the MIC 12-1 Juice Filling Machine?

Reliable Performance: Designed to deliver consistent, high-quality results for every bottle, ensuring customer satisfaction and brand integrity.

Cost-Effective Solution: By combining multiple production stages into one machine, it reduces the need for additional equipment and operational expenses.

Durability and Longevity: Built with robust materials and tested rigorously to provide years of dependable performance.

Applications of the MIC 12-1 Juice Filling Machine

This machine is perfect for producers of various juice types, including fruit juices, vegetable juices, and flavored beverages. Its adaptability to different bottle shapes and sizes further enhances its versatility, making it a valuable asset for businesses seeking to expand their product offerings.

Micmachinery: Your Trusted Partner in Beverage Solutions

At Micmachinery, we take pride in being a leading provider of advanced bottling and filling equipment. Our juice filling machines are engineered with precision and backed by our expertise, ensuring they meet the evolving demands of the beverage industry. From installation to ongoing support, we are dedicated to helping our clients optimize their production lines.

Inline can rinser / can washing machine

The inline can rinser is used to clean the empty cans by clean water before filling, we can add this can rinser in the beginning of filling line. The twist cages are customized with your sample cans. As long as the height and diameter of your cans are different, you need to buy the extra set twist cages to change.

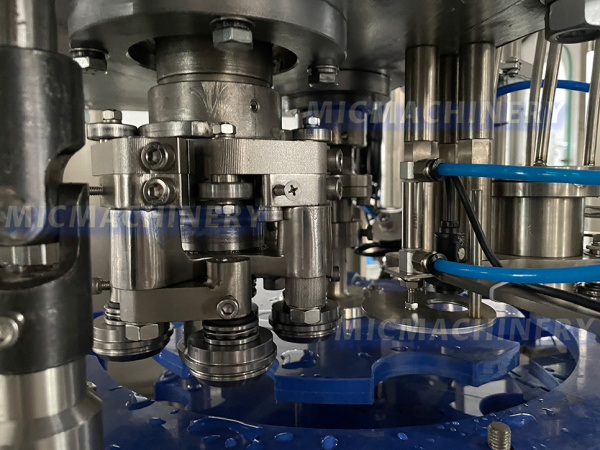

Normal pressure gravity filling system

Monoblock design, filling & seaming process combined in one system. Adopts high precision and normal pressure filling valve make sure the liquid level is high accuracy without loss. Adopts high precision grinding process and food grade 304 stainless steel liquid tank. It will equipped with CIP connector as customer's demand.

Liquid nitrogen doser

Normally, as for cold brew coffee, fruit juice and herbal tea filling, we will suggest our customer to add this liquid nitrogen doser to work with canning machine. In order to extend its shelf life and make sure it tastes good. It also makes the aluminum cans fuller and less prone to deformation.

Aluminum lid seaming system

The “MIC” system is a mechanism actuated, cam-driven seamer with easily adjustable rollers that allow for precise adjustment to from seams that are within can-maker specifications. Seams are formed in under only a second, faster than any other system in its class. Through two past decade’s technology innovation and optimization, the result is revolutionary.

For this production line you might be interested in:

Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine,

vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine.

The machine is a device developed exclusively by MIC machinery on the basis of digesting and absorbing domestic and international (still) pop can filling and seaming machine (sealing machines).

It adopts the normal pressure filling principle.Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination.

It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers’ request. It is the preferred equipment for the medium beer and beverage plant

Mic 12-1 Parameters

|

Power |

1.1Kw |

|

Filling heads |

12piece |

|

Sealing heads |

1piece |

|

Production capacity |

1000-2000CPH based on 330ml |

|

Filling temperature |

0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

More Model And Speed Click

|

Model |

MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application |

Fruit juice, cold coffee, energy drink, alcoholic beverage, herbal tea, non-carbonated drinks and so on |

||||

| Packing Type |

Aluminum cans, tin cans, pet cans, etc |

||||

| Speed | 1000-2000CPH | 1000-2500CPH | 4000-7000CPH | 5000-8000CPH | 8000-12000CPH |

| Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.9(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment