- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

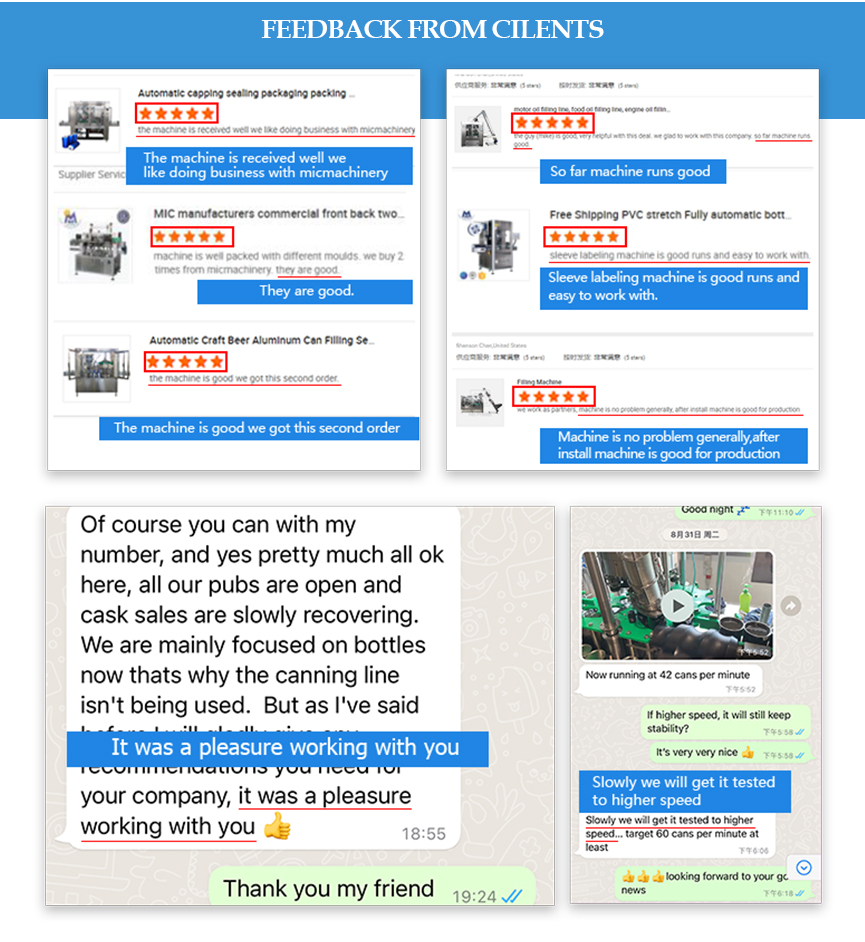

- Customer reviews: click on

At the core of a weight detector's performance lies its precision and accuracy. Equipped with advanced sensors and sophisticated algorithms, these machines can detect even the slightest deviations in weight, ensuring that products are consistently filled to the desired specifications. This high level of sensitivity enables the weight detector to identify potential issues promptly, minimizing the risk of underfilled or overfilled packages.

Performance excellence extends beyond accuracy to encompass speed and efficiency. Modern weight detector are designed to operate seamlessly within high-speed production lines, inspecting thousands of items per hour without compromising on accuracy. This rapid processing capability ensures minimal disruption to production workflows, contributing to overall efficiency and productivity.

Moreover, weight detector play a vital role in waste reduction and cost optimization. By accurately measuring and detecting deviations in weight, these machines help minimize product giveaway and prevent costly recalls due to non-compliance with weight regulations. This not only safeguards profit margins but also enhances sustainability efforts by reducing unnecessary waste.

The versatility of weight detector further enhances their performance. These machines can accommodate a wide range of products, from small packaged goods to larger bulk items, across diverse industries such as food and beverage, pharmaceuticals, and manufacturing. Whether it's ensuring the correct dosage of medication or verifying the weight of packaged goods, weight detectors offer unmatched flexibility in application.

Advanced features augment the performance of modern weight detector, empowering them to deliver comprehensive solutions for quality control and process optimization. Automatic rejection systems swiftly remove non-compliant products from the production line, while data logging capabilities enable detailed record-keeping for traceability and quality assurance purposes. Additionally, connectivity options allow seamless integration with other equipment, facilitating synchronized operation and centralized control within the production environment.

In summary, the performance of a weight detector is multifaceted, encompassing accuracy, speed, efficiency, versatility, and advanced features. As a critical component of quality control processes, these machines ensure the consistent delivery of high-quality products while driving operational excellence and cost savings across industries.

Applications:

1. Used for automatic weight detection, upper and lower limit discrimination or weight classification selection on various automated assembly lines and logistics transportation systems. It can also be used for detection of excess and missing parts after product packaging.

2. Widely used in online testing in pharmaceutical, food, toys, hardware, chemical and other industries.

3. In addition, it can directly replace manual weighing to improve production efficiency and weighing consistency and reliability.Features:

1. Large color LCD touch screen interface, easy to operate and intuitive to display.

2. Supports customization of multiple languages, the default is Chinese and English.

3. It can be set to store 100 kinds of product detection data to facilitate users to switch and call.

4. Equipped with automatic photoelectric detection of empty packages, adjustable conveyor belt speed, and automatic learning function.

5. Parameter settings are password protected and can only be operated by managers.

6. Automatic zero-point tracking system to ensure reliable detection data.

7. The single-chip microcomputer system is independently developed and has a unique filtering algorithm to ensure system stability.

8. The mechanical structure is simple and the buckle-type conveyor belt is easy to disassemble, clean and maintain.

|

Model |

SG-150 |

|

|

Sorting range |

5-500g |

|

|

Sorting accuracy |

±0.1g (depending on product) |

|

|

Minimum scale |

0.1g |

|

|

Sorting speed |

Maximum 180 packages/minute |

|

|

Product Limitation

|

Length 200mm Width 150mm Height 3-200mm |

|

|

Operation mode |

Touch operation |

|

|

Operation interface |

7-inch touch screen |

|

|

Rejection method |

Push plate removal/air blowing removal |

|

|

Belt height from the ground |

750±50mm (can be customized) |

|

|

Machine structure |

Stainless steel (SUS304) |

|

|

Power supply |

AC110V/220V 50-60HZ |

|

|

Power |

100W |

|

|

Countertop size |

316mm*150mm |

|

|

Weight |

60KG |

|

|

Optional functions |

Three-color alarm light, RS485 output port, rejection box |

|

|

Name |

Brand |

|

Load cell |

HBM Germany |

|

Inverter |

Delta |

|

Touch screen |

Taiwan Weilun 7 inches |

|

Motor |

CUHK |

|

Conveyor Belt |

Swiss Habster |

|

Photoelectric Sensor |

Autonics |

|

Cylinder |

Yadek |

|

Machine material |

Stainless steel SU304 |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment