- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine adopts PLC control, according to the filling cup, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling.

1. Available with standard conveyor or with pucks for unstable cups

2. Flexible design

3. Very fast and easy changeover of format size

4. Docking filling station model available

5. Anti-dripping filling nozzle

Soft drink filling machines come in a variety of types, including fully automated, semi-automated, and manual machines. Each type of machine has its own set of advantages and is suited for different production needs and budgets.

Fully automated soft drink filling machines are designed to handle large-scale production runs and can fill hundreds of bottles or cans per minute. They are equipped with advanced features such as electronic controls, sensors, and programmable logic controllers (PLCs) that allow for precise and consistent filling.

Semi-automated soft drink filling machines automate some aspects of the filling process but still require some manual intervention from the operator. These machines are ideal for small to medium-scale beverage production operations that do not require the high-speed output of fully automated machines.

Manual soft drink filling machines are simple and easy to operate and are typically used in small-scale operations where automation is not necessary or cost-effective. They consist of a container to hold the soft drink, a nozzle to dispense the liquid, and a lever or foot pedal to control the flow of the liquid.

Overall, soft drink filling machines are an essential tool for beverage manufacturers who need to fill containers with soft drinks efficiently and effectively. The type of machine chosen depends on production needs and budget, and manufacturers should carefully evaluate their options before selecting a machine that best suits their needs.

At Micmachinery, we pride ourselves on delivering high-quality solutions to the beverage industry. The MIC-V01 Soft Drink Filling Machine is a cutting-edge product designed to meet the specific needs of small to medium-scale beverage businesses. Offering exceptional efficiency and reliability, this machine is the perfect choice for businesses looking to streamline production while maintaining top-notch quality.

Why Choose the MIC-V01 Soft Drink Filling Machine?

1. Affordable Pricing

One of the key advantages of this model is its competitive soft drink filling machine price. It’s an ideal choice for businesses that need a high-performance machine without stretching their budget, making it an excellent investment for startups and growing enterprises.

2. Optimal Production Capacity

With a capacity of 600-800 pieces per hour, this soft drink filling machine is tailored to meet moderate production needs. Its output makes it highly suitable for small to medium-sized production facilities aiming to improve efficiency.

3. Versatile Packaging Options

The MIC-V01 excels in its ability to handle a wide variety of container types and sizes. This flexibility makes it an essential component of any soft drink packaging machine lineup, catering to bottles, cans, and other custom packaging solutions.

4. High-Quality Construction

Manufactured using food-grade stainless steel, the machine guarantees hygiene and durability. Its robust construction ensures long-term reliability even under demanding production conditions.

Features of the MIC-V01 Soft Drink Filling Machine

Precise Filling Accuracy: Advanced technology ensures consistent filling volumes, reducing product wastage.

Compact Design: Ideal for facilities with limited space, this machine offers high performance without requiring a large footprint.

User-Friendly Operation: Simple controls allow operators to run the machine with ease, minimizing the need for extensive training.

Energy Efficiency: Designed to operate with minimal energy consumption, lowering operational costs for businesses.

Easy Maintenance: Components are easy to disassemble and clean, ensuring minimal downtime during maintenance.

Applications

The MIC-V01 Soft Drink Filling Machine is suitable for a wide range of beverages, including:

Carbonated soft drinks.

Sparkling water.

Flavored sodas and energy drinks.

Its adaptability to various packaging solutions ensures seamless integration into any soft drink packaging machine workflow.

Why Micmachinery?

As a trusted name in beverage production machinery, Micmachinery combines innovation, reliability, and cost-effectiveness. Our commitment to quality ensures that our customers receive the best value for their investment.

The MIC-V01 Soft Drink Filling Machine exemplifies this commitment. Whether you are focusing on scaling your operations or improving efficiency, this machine delivers exceptional performance at a highly competitive soft drink filling machine price.

Contact Us

Take your beverage production to the next level with the MIC-V01 Soft Drink Filling Machine. Contact Micmachinery today to learn more about how this machine can revolutionize your production line. Let our team of experts guide you to the ideal solution for your business needs.

cup loading station

Put the finished cups into the cup loading station. When the machine receives the start signal, the cup loading station will automatically drop the cups to be filled into the mold accurately, which is convenient for later filling.

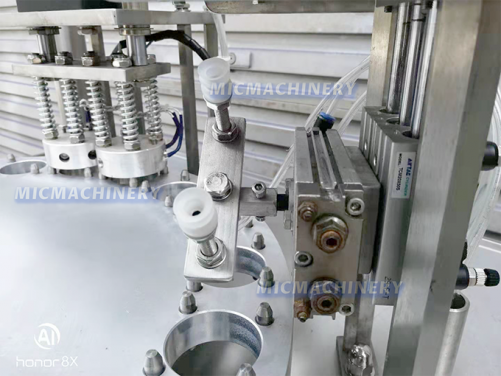

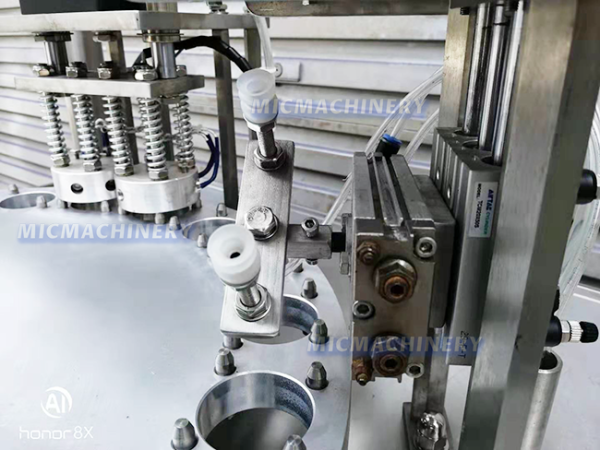

foil loading sucking disks

The device is designed to absorb the sealed tin foil film with a moderate suction force. When the cup reaches the desired position, the two pieces of foil are automatically absorbed and placed on the cup with precision. The working process is time-saving and stable

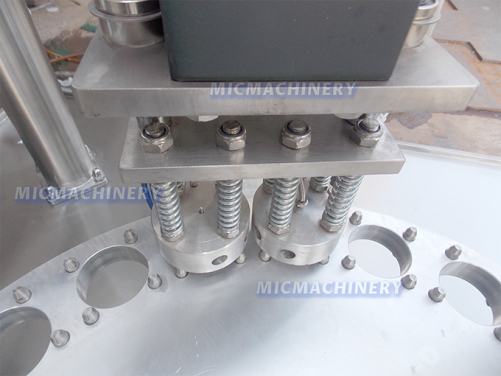

filling head

This machine adopts automatic piston filling, can ensure the precise filling you need filling quantity, the whole process without drip leakage, no waste of materials.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Diameter |

1100*1100*1600mm |

|

Weight |

350KGS |

|

Power |

2 KW |

|

Voltage |

110V/ 60Hz 1P |

|

Air pressure |

0.6-0.8Mpa |

|

Capacity |

600-800 pcs/hour |

|

Air consumption |

0.6m³/min |

|

Heating type |

electrical heated |

|

Working position |

6 |

|

Machine frame |

SUS 304 |

|

Item |

Brand |

|

PLC |

OMRON |

|

Touch Screen |

WEINVIEW |

|

Motor |

DINGYI |

|

Magnetic Valve |

JELPC |

|

AC Contactor |

SCHNEIDER |

|

Temperature Control |

SIMP |

|

Relay, Circuit Breaker |

DELIXI |

|

Divider |

REP |

|

Pneumatic Component |

AKS |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment