- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

oft drink bottling machines are specialized equipment used in the beverage industry for bottling carbonated and non-carbonated drinks, such as sodas, juices, and energy drinks. These machines are designed to handle high-speed production lines and can fill and package large volumes of liquid into bottles or cans. In this article, we will explore the key features and benefits of soft drink bottling machines and how they can help beverage companies improve their production process.

1. High-Speed Production: Soft drink bottling machines are designed for high-speed production lines, with filling speeds of up to 800 bottles per hour, allowing companies to produce large volumes of drinks quickly and efficiently.

2. Versatile: These machines can handle a variety of bottle sizes and shapes, making them a versatile option for beverage companies.3. Accurate Filling: Soft drink bottling machines use advanced technology to ensure accurate filling levels, reducing waste and improving product quality.

4. Hygienic: Soft drink bottling machines are designed to meet strict hygiene standards, with easy-to-clean surfaces and contact parts made from stainless steel.

5. Automated Operation: These machines can operate automatically, with minimal human intervention, reducing labor costs and improving efficiency.

6. Complete Solution: Soft drink bottling machines can handle all aspects of the bottling process, from bottle cleaning and filling to labeling and packaging, providing a complete solution for beverage companies.

7. Cost-Effective: Soft drink bottling machines are a cost-effective option for companies looking to increase their production capacity and reduce labor costs.

In summary, soft drink bottling machines are an essential piece of equipment for companies in the beverage industry looking to improve their production process and increase efficiency. Their high-speed production, accuracy, hygiene, automation, and complete solution make them a cost-effective and reliable solution for filling and packaging soft drinks.

The soda bottle filling machine price is a key factor for businesses when considering the purchase of equipment for their beverage production needs. This machine plays a crucial role in ensuring precise and efficient filling of soda into bottles, which directly impacts the quality and consistency of the final product.

The cost of a soda bottle filling machine can vary depending on its features, capacity, and automation level. For instance, fully automated models generally come at a higher soda bottle filling machine price compared to manual options. These automated machines are designed for high-speed operations and require minimal manual intervention, making them ideal for large-scale production environments.

In contrast, a manual soda bottle filling machine offers a more budget-friendly option. While it requires more hands-on operation and is better suited for smaller-scale operations or startups, it still delivers reliable performance for filling soda into bottles.

When assessing the soda bottling plant price, it's important to consider the overall investment in a complete production line. The soda bottling plant price includes not only the filling machines but also additional equipment such as capping machines, labeling systems, and conveyors. This comprehensive setup ensures a seamless and efficient bottling process, from filling to packaging.

Overall, the choice between a manual and automatic soda bottle filling machine, along with the consideration of the soda bottling plant price, depends on the specific needs and scale of the beverage production operation. Each option offers its own set of advantages, and the investment should align with the production goals and budget constraints of the business.

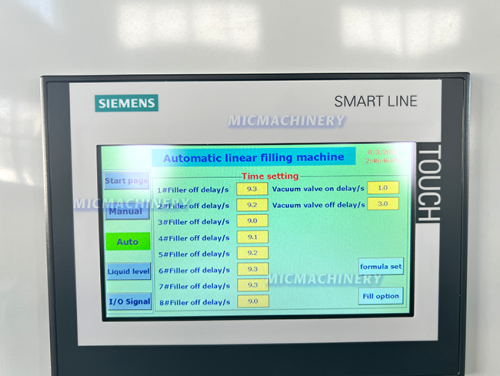

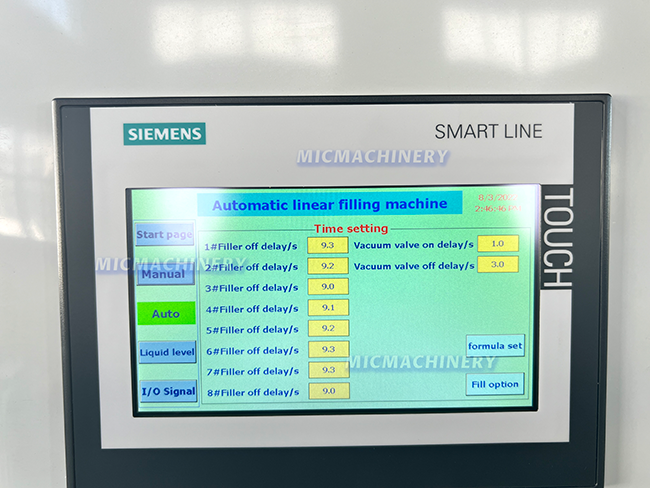

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment