- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

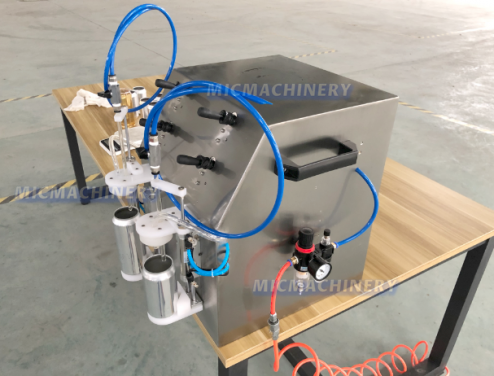

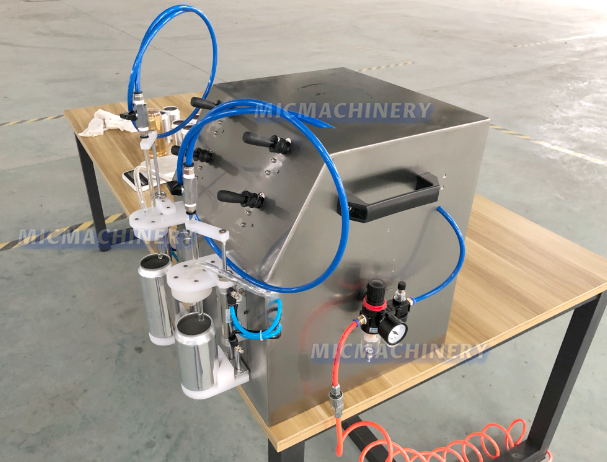

Manual Beer Can Filling Machine is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

The small juice filling machine is an ideal solution for beverage producers who require a compact and efficient system for filling juice into bottles or containers. This machine is particularly well-suited for small to medium-scale production environments where space and budget considerations are paramount. Despite its smaller size, the small juice filling machine delivers high performance and precision, ensuring that each bottle is filled accurately and consistently.

One of the key features of this machine is its adaptability. The small juice filling machine is often equipped with a 2 nozzle juice filling machine system, which allows for the simultaneous filling of two bottles. This dual-nozzle configuration significantly increases the machine's productivity without compromising the accuracy of the fill. The nozzles are designed to handle a wide range of juice viscosities, from thin, clear liquids to thicker, pulp-rich juices, making this machine versatile across different juice types.

For operations that require a bit more control and flexibility, the semi automatic juice filling machine is an excellent option. The semi automatic juice filling machine provides operators with the ability to manually control certain aspects of the filling process, such as the fill volume and speed, while still benefiting from automated precision where it counts. This level of control is particularly beneficial for small-batch production or when working with delicate juice formulations that require careful handling.

The small juice filling machine is also designed with ease of use and maintenance in mind. Its compact footprint makes it easy to integrate into existing production lines, and its straightforward operation reduces the need for extensive training. Maintenance is simplified through the use of high-quality, food-grade materials that are easy to clean and sanitize, ensuring that the machine meets stringent hygiene standards.

In summary, the small juice filling machine is a powerful tool for juice producers looking to optimize their production efficiency without sacrificing quality. Whether you choose a 2 nozzle juice filling machine for increased throughput or a semi automatic juice filling machine for more control over the filling process, this equipment offers the reliability and precision needed to produce high-quality juice products.

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

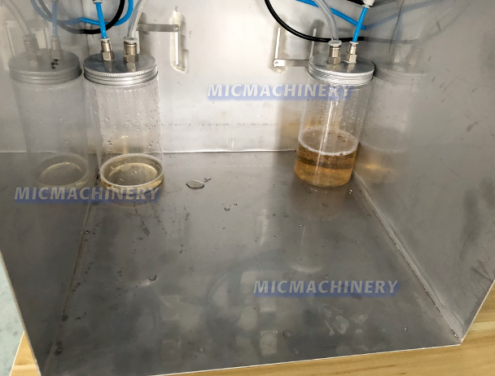

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment