- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

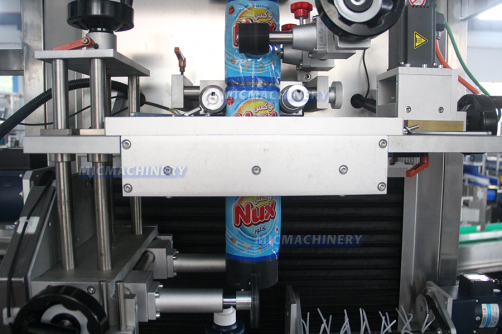

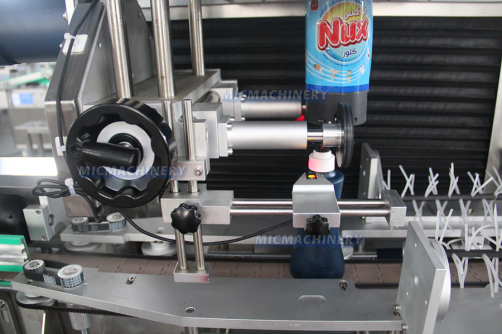

Sleever machines, also known as sleeving machines or sleeve labeling machines, are used in various industries to label and package products with shrinkable sleeves. These machines offer a range of benefits to manufacturers, including:

1. Versatility: Sleever machines can handle a variety of sleeve sizes and shapes, making them suitable for a wide range of products, from cans and bottles to jars and containers.

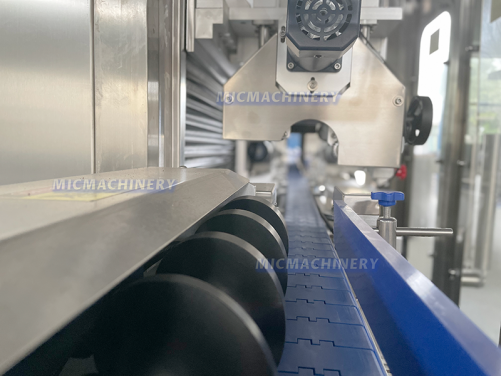

2. High speed and efficiency: These machines can apply sleeves at high speeds, which means faster production and higher output. Additionally, automated sleeving machines can reduce labor costs and improve overall efficiency.

3. Improved branding: Sleeve labeling allows for full-color, high-quality graphics, which can help products stand out on the shelf and improve brand recognition.

4. Tamper-evident packaging: Sleever machines can apply shrink sleeves that provide a tamper-evident seal, which helps ensure product safety and integrity.

5. Cost-effective: Sleever machines offer a cost-effective labeling solution compared to other labeling methods, such as pressure-sensitive labeling or in-mold labeling.

6. Environmental benefits: Sleeve labeling uses less material than other labeling methods, reducing waste and environmental impact. Additionally, some sleeve materials can be recycled or made from biodegradable materials.

Overall, sleever machines provide manufacturers with an efficient and cost-effective solution for labeling and packaging products. The versatility, speed, and branding benefits make them a popular choice for companies looking to improve their packaging processes.

Sleever machines offer several benefits over traditional labeling methods. They are highly versatile, capable of handling a wide range of product shapes and sizes, and can apply labels at high speeds, making them ideal for high-volume production environments. Additionally, because the labels are applied as sleeves, they can cover irregularly shaped or non-flat surfaces, providing more space for branding and product information.

In this competitive business environment, sleever machines are increasingly important to help manufacturers increase production efficiency, reduce waste and labor costs, and enhance product presentation.

|

Host machine |

AC220V, 50/60HZ, 3KW, single-phase |

|

Production speed |

9000 b/h as 100mm label |

|

Standard length |

The standard length of label is 300mm and the speed can be adjusted accord to customer's requirements. The speed will be faster if the label is shorter. |

|

Diameter of bottle body |

φ40mm-φ100mm |

|

Length of label |

100mm |

|

Thickness of label |

0.045mm |

|

Material of label |

PVC、PET、 OPS |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment