- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

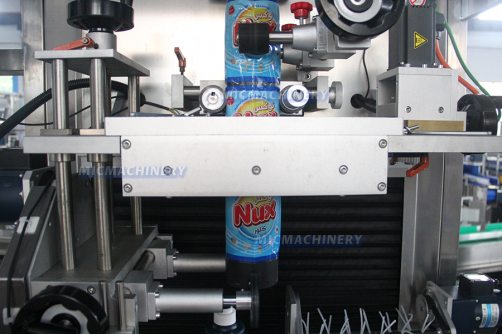

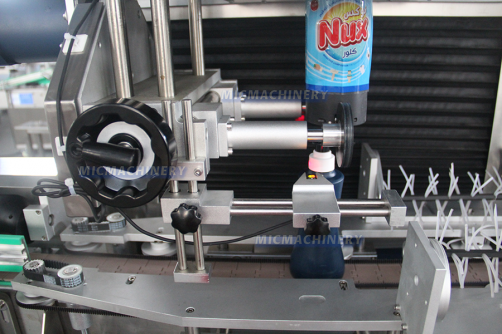

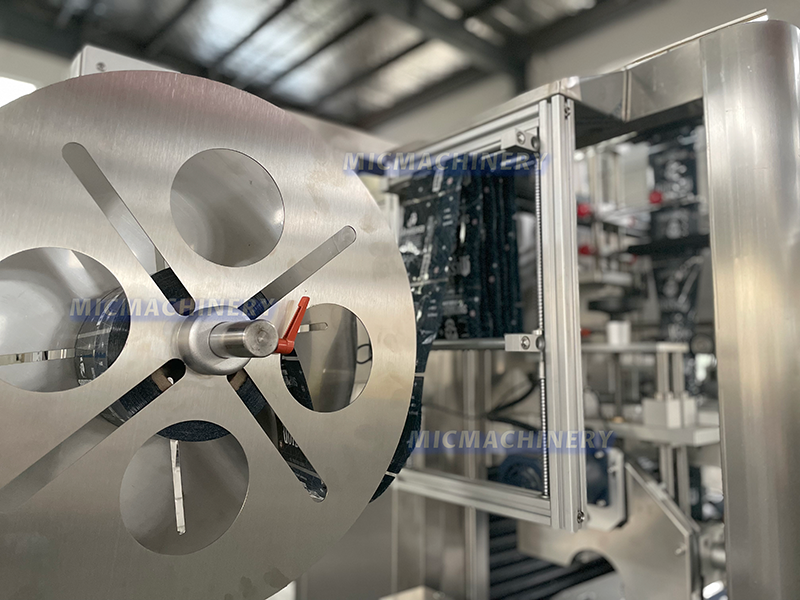

A sleeve machine is an essential equipment for product labeling and packaging in various industries. The machine applies shrink sleeves or stretch sleeves onto containers, bottles, and other products. Here are some of the key features and benefits of a sleeve machine:

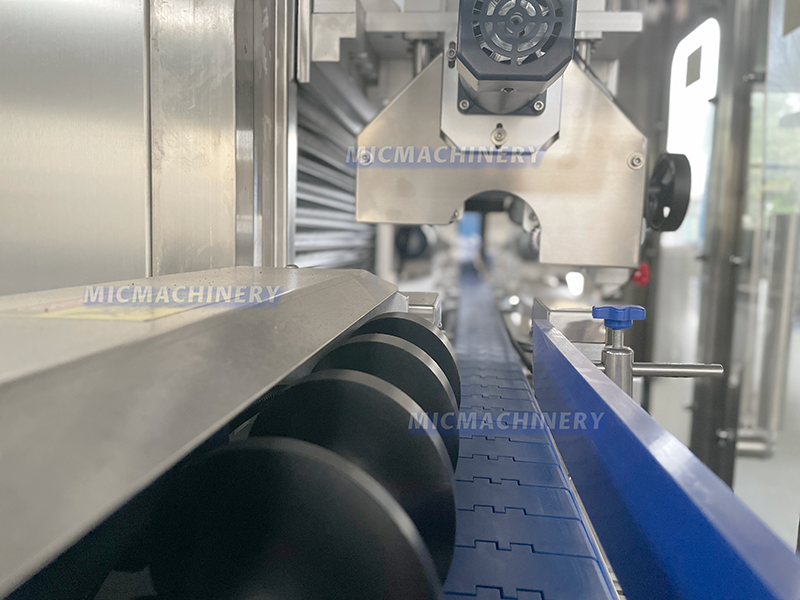

1. High-Speed Operation: Sleeve machines are designed to operate at high speeds, making them ideal for large-scale production lines. With fast labeling and packaging speeds, they help businesses achieve higher production output and efficiency.

2. Versatility: Sleeve machines can handle a wide range of container shapes, sizes, and materials. They can be used for labeling bottles, jars, cans, cups, and other products.

3. Precise Labeling: The machine applies labels with precision, ensuring accurate and consistent placement on every container. This helps businesses maintain brand consistency and quality.

4. Cost-Effective: Sleeve machines are a cost-effective solution for labeling and packaging needs. They eliminate the need for manual labor, reducing costs and increasing production efficiency.

5. Improved Shelf Appeal: Sleeving can enhance product packaging, providing a 360-degree label coverage for better shelf appeal. This can attract more customers and increase sales.

6. Sustainability: Sleeve machines can be used with eco-friendly materials such as recyclable films, reducing environmental impact and improving sustainability.

Overall, a sleeve machine offers businesses a fast, efficient, and cost-effective solution for labeling and packaging products. With precise labeling, versatility, and sustainability features, a sleeve machine is a valuable investment for any manufacturing or packaging operation.

Sleeve machines are commonly used in several industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. They offer several advantages over other labeling methods. One of the significant benefits is their ability to handle a wide range of product shapes and sizes with ease. This versatility makes sleeve machines ideal for high-volume production environments where labeling speed is essential.

In addition, sleeve machines are highly customizable, allowing manufacturers to choose from different materials, shapes, and sizes to achieve the desired branding and product information. The labels can also be applied with high precision, ensuring a consistent look and feel across all products.

With the growing competition in the market, sleeve machines are increasingly becoming essential for manufacturers looking to increase production efficiency, reduce waste and labor costs, and enhance their product presentation.

|

Input Power |

Input Power |

|

Input Voltage |

3,380 1220VAC |

|

Production Efficiency |

150 bottle / min |

|

Size Of Host Machine |

L2000mm*W850mm*H2000mm |

|

Applicable Diameter Of Bottle Body |

30-55mm |

|

Applicable Length Of Label |

30-150mm |

|

Applicable Thickness Of Label |

0.03-0. 13mm |

|

Applicable Intemal Diameter Of Paper Tube |

5"-10" free adjustment |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment