- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

1. Versatility: A sleeve labeling machine can handle various container shapes and sizes, making it a versatile labeling solution for companies in different industries.

2. High-Quality Labeling: The labels produced by a sleeve labeling machine provide a 360-degree coverage of the container, which offers a large printable area for branding, promotional messages, and product information. The result is a label that is visually appealing, informative, and provides tamper-evident security.

3. Speed and Efficiency: Sleeve labeling machines can handle high-speed production lines, with labeling speeds of up to 500 bottles per minute, allowing companies to label large volumes of products quickly and efficiently.

4. Cost-Effective: Sleeve labels are made from cost-effective materials like PVC or PET, making them an affordable labeling option for companies looking to keep costs low.

5. Eco-Friendly: Sleeve labels are recyclable, making them an eco-friendly labeling option for companies looking to reduce their environmental impact.

6. Improved Branding and Marketing: The 360-degree coverage of the container provides ample space for branding and marketing, allowing companies to promote their products and increase sales.

7. Tamper-Proof: Sleeve labels are designed to provide tamper-evident security, making them an ideal labeling solution for pharmaceuticals, cosmetics, and other consumer goods that require safety and security measures.

In summary, a sleeve labeling machine is a versatile, cost-effective, and efficient labeling solution that provides high-quality, 360-degree labeling with excellent branding and promotional opportunities. Its ability to handle various container shapes and sizes, speed and efficiency, eco-friendliness, and tamper-evident security make it an essential piece of equipment for companies in various industries looking to improve their labeling process and increase efficiency.

Bottle feeding device

The bottle feeding device in a shrink sleeve labeling machine is designed to ensure smooth, continuous, and precisely timed delivery of bottles into the labeling station. It typically consists of a motor-driven conveyor system, bottle spacing mechanism, and alignment guides. This unit plays a critical role in maintaining labeling accuracy and production efficiency by automatically adjusting the bottle spacing and orientation before labeling. It accommodates various bottle shapes and sizes and is fully synchronized with the labeling machine’s speed to prevent jams or misalignment. Built with stainless steel and wear-resistant components, the device is reliable, hygienic, and ideal for high-speed production lines.

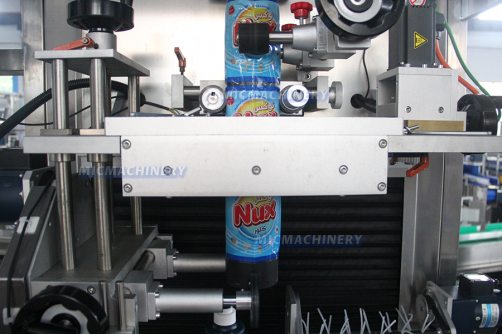

auto sleeving device

The auto sleeving device is the core component of a shrink sleeve labeling machine, responsible for accurately applying shrink film sleeves onto bottles or containers at high speed. It operates by feeding pre-cut or continuous sleeve material from a roll, precisely cutting and positioning each sleeve over the bottle’s neck or body using synchronized servo-controlled mechanisms. The system ensures smooth and consistent sleeve placement even at high speeds, minimizing misalignment or sleeve distortion. Designed for compatibility with round, square, or irregular-shaped containers, the device features an adjustable mandrel system and high-precision cutting blades. With its robust stainless-steel construction and easy integration into various production lines, the auto sleeving device offers exceptional reliability, accuracy, and operational efficiency for modern packaging needs.

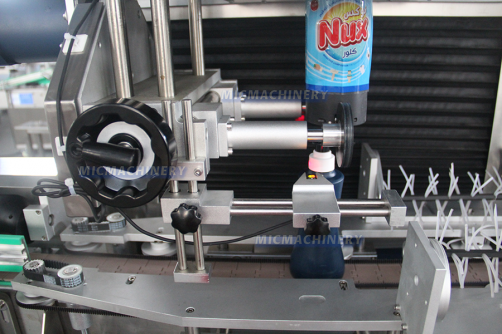

The Send Label Wheel is a precision component in a shrink sleeve labeling machine responsible for feeding and guiding the label film accurately from the roll to the cutting unit. It works in coordination with sensors and servo motors to maintain consistent tension and label positioning, ensuring smooth and continuous operation without film slippage or stretching. The wheel is typically made from wear-resistant rubber or composite material to provide stable grip and minimal abrasion to the film. By synchronizing with the machine’s labeling cycle, the Send Label Wheel plays a key role in achieving high-speed, high-accuracy sleeving with minimal film waste and downtime. Its adjustable speed and pressure settings allow compatibility with various film materials and thicknesses.

|

Input Power |

Input Power |

|

Input Voltage |

3,380 1220VAC |

|

Production Efficiency |

150 bottle / min |

|

Size Of Host Machine |

L2000mm*W850mm*H2000mm |

|

Applicable Diameter Of Bottle Body |

30-55mm |

|

Applicable Length Of Label |

30-150mm |

|

Applicable Thickness Of Label |

0.03-0. 13mm |

|

Applicable Intemal Diameter Of Paper Tube |

5"-10" free adjustment |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment