- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Shrink Sleeve Label Machine: Revolutionizing Bottle Labeling

In the world of packaging and labeling, shrink sleeve technology has become increasingly popular due to its versatility and aesthetic appeal. A shrink sleeve label machine is a specialized piece of equipment designed to apply shrink sleeves onto bottles or containers with precision and ease.

Shrink sleeve label machines use a range of technologies to apply the sleeve to the bottle, such as hot air or steam, which shrinks the sleeve to fit snugly onto the bottle's shape. The result is a secure, high-quality label that enhances the visual appeal of the product, while also offering protection from external contaminants.

These machines come in a variety of sizes and configurations, making them suitable for both small and large-scale production facilities. They can accommodate a wide range of bottle shapes and sizes, making them an ideal choice for manufacturers who require flexibility in their labeling process.

The benefits of using a shrink sleeve label machine are many. Firstly, these machines are incredibly efficient and can apply labels at a high rate, ensuring consistent quality while reducing labor costs. By automating the labeling process, manufacturers can streamline their operations and increase their output, leading to higher profitability.

Shrink sleeve labels are also a cost-effective solution to labeling. Shrink sleeves are less expensive than traditional labeling methods, such as pressure-sensitive labels, and can be printed in high resolution with complex graphics and designs. This allows manufacturers to create eye-catching packaging that stands out on store shelves, helping to boost sales and brand recognition.

In conclusion, a shrink sleeve label machine is a valuable addition to any packaging and labeling operation, providing a cost-effective and efficient solution to the challenges of bottle labeling. Whether you're a small craft brewery or a large-scale beverage manufacturer, investing in a shrink sleeve label machine can help you streamline your operations, increase your output, and enhance your product's visual appeal.

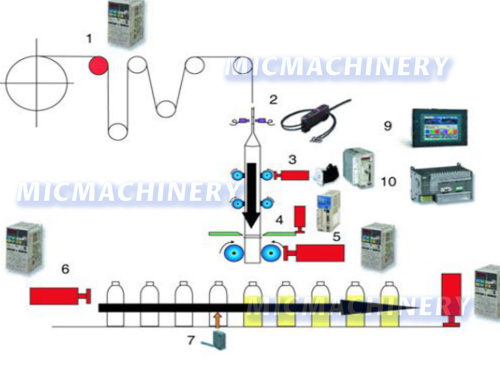

Technology Procedure:

Main technical parameters of the

equipment:

Voltage:

1. Host machine; AC220V, 50/60HZ, 4KW, single-phase

2. Production speed: 18000-21000 b/h as 100mm label.

3.The standard length of label is 300mm and the speed can be adjusted accord to customer’s requirements. The speed will be faster if the label is shorter.

4. Diameter of bottle body : ∮40mm-∮100mm

5. Length of label: 100mm

6. Thickness of label: 0.045mm

7. Material of label:PVC、 PET、 OPS

SLM-1800 Steam Shrink Tunnel

1. In the case of different and irregular round bottles, square bottles and flat bottles etc, the new-style both steam and electricity shrinking oven is easy to adjust and maintain. It has an even shrinking .2. The distribution of low-pressure steam drum and sqouting way of steam are uniform and designed with seamless tube.

3. The nozzle is divided to be adjustable three segments and the height , position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect.

4 .The whole machine is made of stainless steel with heat preservation, which not only saves energy, but also comply with the international safety standard.

5 .The stainless steel defrosting tray collects condense water.

6. The whole machine adopts the water-proof design with the convenience of easy operation and low maintenance.

Stream Generator

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency.

Quotation for the machine

|

Item |

Name |

Amount |

Unit |

Configuration |

Unit Price

|

Total price

|

Remark |

|

1 |

Sleeve labeling machine |

1 |

set |

4kw |

|

|

|

|

2 |

Shrink tunnel |

1 |

set |

0.75kw |

|

|

|

|

3 |

Steam generator |

1 |

set |

24kw |

|

|

|

|

4 |

mold |

2 |

pcs |

|

|

|

|

|

5 |

Conveyor |

7 |

m |

|

|

|

|

|

|

|||||||

Technical Parameters

|

Input Power Supply of Blower |

1,220VAC 0.75KW |

|

Working Pressure |

≤0.1Mpa |

|

Weight |

230kg |

|

Steam Consumption |

20-30Kg/h |

|

Size of Oven Body |

L1800mm×W600mm×H450mm |

|

Transporting Speed |

0-35m/min |

|

Input Power Supply |

220V 24kw

|

|

Steam Pressure |

0.25-0.4Mpa |

|

Vapor Generation |

24kg/h |

|

External Dimension |

L600mm x W550mm x H1200mm |

|

Weight |

96Kg |

Detail list of Selecting and Using the Accessory

Name

Amount

Unit

Brand

Origin

PLC

1

Set

Siemens

German

Touch Screen

1

Set

Siemens

German

High-speed Optical Fiber Sensors

2

Pc

Panasonic

Japan

OPTICAL SENSORS

4

Pc

Panasonic

Japan

Label Sending Servo Motor

2

Set

Panasonic

Japan

Label Cutting Servo Motor

2

Set

Panasonic

Japan

Bottle Separate Ac Motor

1

Set

Panasonic

Japan

Bottle Separate Converter

1

Set

Panasonic

Japan

Bottle Carrying Ac Motor

1

Set

Panasonic

Japan

Bottle Carrying Converter

1

Set

Panasonic

Japan

Conveyor Converter

1

Set

Panasonic

Japan

Ac Contactor

2

Pc

Schneider

France

2P air switch

1

Pc

DELIXI

china

24V relay

13

Pc

Schneider

France

Toolbox detailed list

|

NO |

Name |

Specification |

Quantity |

|

1 |

Open wrench |

14、12、8、10(4 total) |

1set |

|

2 |

Movement wrench |

250*30 |

1set |

|

3 |

Inner hexagonal wrench |

7 total |

1set |

|

4 |

Clubs screwdriver |

6*100mm、3*75mm |

1set |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment