- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

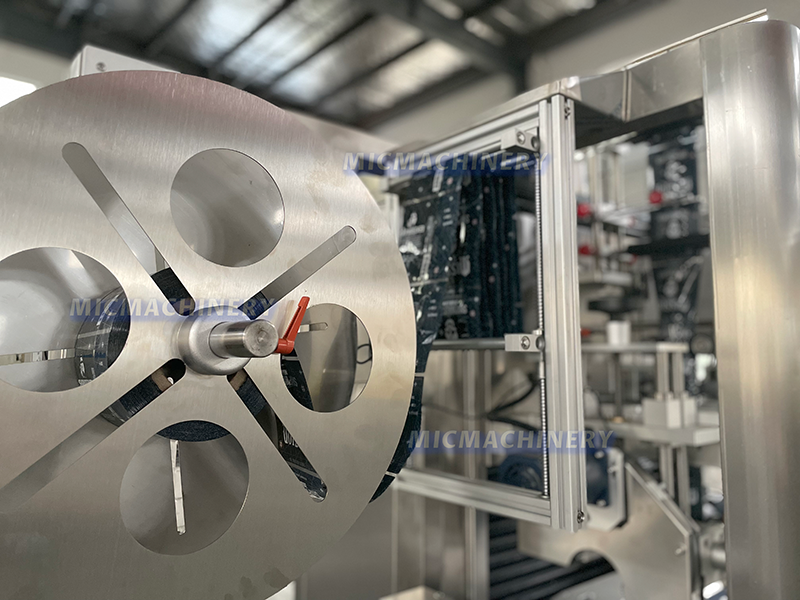

Shrink sleeve applicator packaging machines are widely used in the packaging industry for labeling bottles, cans, and containers with shrink sleeves. These machines offer several key features and benefits that make them popular in the market.

1. High-speed labeling: Shrink sleeve applicator packaging machines are capable of labeling bottles and containers at high speeds, making them ideal for large-scale production lines. They can label up to 600 containers per minute, increasing the efficiency of the packaging process.

2. Accurate labeling: The machines use advanced sensors and software to accurately position and apply the shrink sleeves onto the containers, ensuring that the label is centered and straight. This prevents mislabeling and ensures that the product looks professional and consistent.

3. Versatility: Shrink sleeve applicator packaging machines can label containers of different shapes and sizes, from small vials to large bottles. They can also apply sleeves with intricate designs and graphics, allowing for greater flexibility in packaging and branding.

4. Cost-effective: Shrink sleeve labeling is a cost-effective way of labeling products as compared to traditional labeling methods like pressure-sensitive labels. The cost of shrink sleeves is relatively lower, and the machines can label containers with minimal wastage.

5. Brand visibility: Shrink sleeves offer a 360-degree branding surface, providing greater visibility for the product on the shelf. The sleeves can be printed with high-quality graphics and designs, making the product more attractive and appealing to consumers.

6. Tamper-evident: Shrink sleeves provide a tamper-evident seal for products, ensuring that the product has not been opened or tampered with before purchase. This improves the safety and integrity of the product and provides reassurance to consumers.

In summary, shrink sleeve applicator packaging machines offer a range of key features and benefits that improve the efficiency, accuracy, and cost-effectiveness of the packaging process. They also provide greater branding opportunities and improved product safety and security.

1. High-speed labeling: Shrink sleeve applicator packaging machines are capable of labeling bottles and containers at high speeds, making them ideal for large-scale production lines. They can label up to 600 containers per minute, increasing the efficiency of the packaging process.

2. Accurate labeling: The machines use advanced sensors and software to accurately position and apply the shrink sleeves onto the containers, ensuring that the label is centered and straight. This prevents mislabeling and ensures that the product looks professional and consistent.

3. Versatility: Shrink sleeve applicator packaging machines can label containers of different shapes and sizes, from small vials to large bottles. They can also apply sleeves with intricate designs and graphics, allowing for greater flexibility in packaging and branding.

4. Cost-effective: Shrink sleeve labeling is a cost-effective way of labeling products as compared to traditional labeling methods like pressure-sensitive labels. The cost of shrink sleeves is relatively lower, and the machines can label containers with minimal wastage.

5. Brand visibility: Shrink sleeves offer a 360-degree branding surface, providing greater visibility for the product on the shelf. The sleeves can be printed with high-quality graphics and designs, making the product more attractive and appealing to consumers.

6. Tamper-evident: Shrink sleeves provide a tamper-evident seal for products, ensuring that the product has not been opened or tampered with before purchase. This improves the safety and integrity of the product and provides reassurance to consumers.

In summary, shrink sleeve applicator packaging machines offer a range of key features and benefits that improve the efficiency, accuracy, and cost-effectiveness of the packaging process. They also provide greater branding opportunities and improved product safety and security.

Shrink sleeve applicator packaging machines are used in the packaging industry to apply shrink sleeves to various types of containers, such as bottles, cans, and jars. These machines use a heat source to shrink the sleeve onto the container, creating a tight, tamper-evident seal.

Shrink sleeve applicator packaging machines offer a number of benefits, including fast and efficient application of sleeves, precise and consistent application, and the ability to use a variety of sleeve materials. They are also versatile, able to handle a wide range of container shapes and sizes, and can be integrated into existing production lines. Overall, shrink sleeve applicator packaging machines are a valuable tool for manufacturers looking to improve their packaging processes and create high-quality, visually appealing products.

Shrink sleeve applicator packaging machines offer a number of benefits, including fast and efficient application of sleeves, precise and consistent application, and the ability to use a variety of sleeve materials. They are also versatile, able to handle a wide range of container shapes and sizes, and can be integrated into existing production lines. Overall, shrink sleeve applicator packaging machines are a valuable tool for manufacturers looking to improve their packaging processes and create high-quality, visually appealing products.

Sleeve labeling machine for cans

Sleeve labeling machine for bottles

|

Input Power |

8.0kw |

|

Input Voltage |

3,380 1220VAC |

|

Production Efficiency |

600 bottle/min |

|

Size Of Host Machine |

L2800mm*W1200mm*H2200mm |

|

Applicable Diameter Of Bottle Body |

48-96mm |

|

Applicable Length Of Label |

30-250mm |

|

Applicable Thickness Of Label |

0.03-0.13mm |

|

Applicable Intemal Diameter Of Paper Tube |

5"- -10" free adjustment |

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment