- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

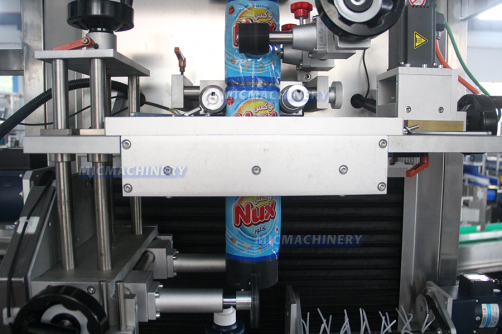

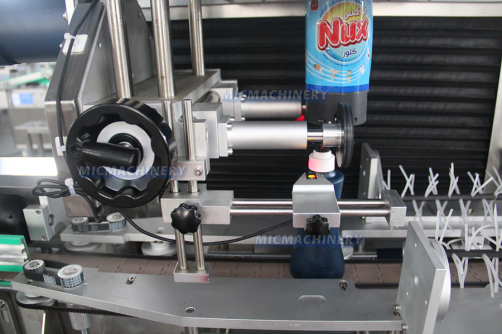

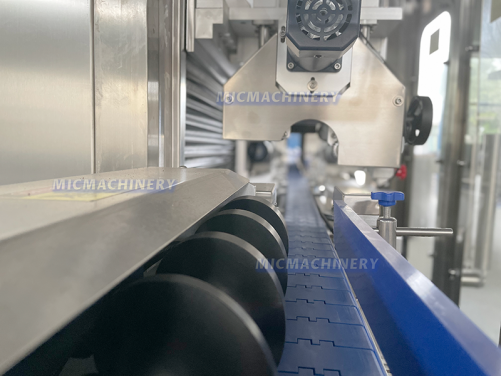

Shrink sleeve applicator machine, also known as shrink label applicator machine, is a popular type of labeling equipment used in various industries such as food, beverage, pharmaceuticals, and cosmetics. The machine applies a heat-shrinkable film label or sleeve onto the container or product, creating a tight, tamper-evident seal and enhancing the packaging aesthetics. Shrink sleeve applicator machines are highly efficient and can handle a wide range of bottle shapes and sizes, making them a preferred choice for high-volume labeling applications.

The use of shrink sleeve applicator machines offers several key benefits to manufacturers. These machines can provide consistent, high-quality labeling results, reduce labor costs, and improve production efficiency. Shrink sleeve labels also offer excellent print quality and durability, allowing for vibrant and eye-catching designs to enhance brand recognition and product appeal. In addition, shrink sleeve labels are 100% recyclable, making them an eco-friendly packaging option.

In this article, we'll explore the key features and benefits of shrink sleeve applicator machines in more detail.

The key features of a shrink sleeve applicator machine include its ability to accurately position and apply sleeves at high speeds, its versatility in handling a wide range of container sizes and shapes, and its ease of use and maintenance. Additionally, many shrink sleeve applicator machines are designed with user-friendly touchscreens and automation capabilities that reduce the need for manual adjustments and increase productivity.

The benefits of using a shrink sleeve applicator machine include enhanced product branding and labeling, increased efficiency and productivity, reduced labor costs, and improved quality control. With precise and consistent application of shrink sleeves, companies can increase their product visibility and shelf appeal, which can lead to higher sales and customer satisfaction. Additionally, the speed and automation capabilities of these machines can significantly reduce labor costs and increase production rates, ultimately resulting in higher profitability.

|

Host machine |

AC220V, 50/60HZ, 3KW, single-phase |

|

Production speed |

9000 b/h as 100mm label |

|

Standard length |

The standard length of label is 300mm and the speed can be adjusted accord to customer's requirements. The speed will be faster if the label is shorter. |

|

Diameter of bottle body |

φ40mm-φ100mm |

|

Length of label |

100mm |

|

Thickness of label |

0.045mm |

|

Material of label |

PVC、PET、 OPS |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment