- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

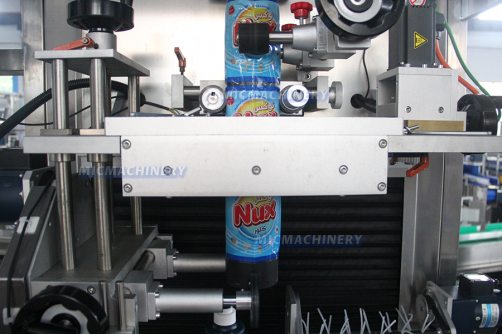

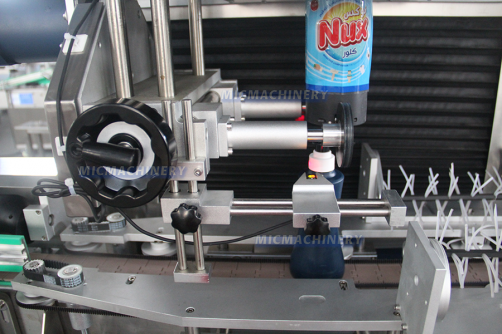

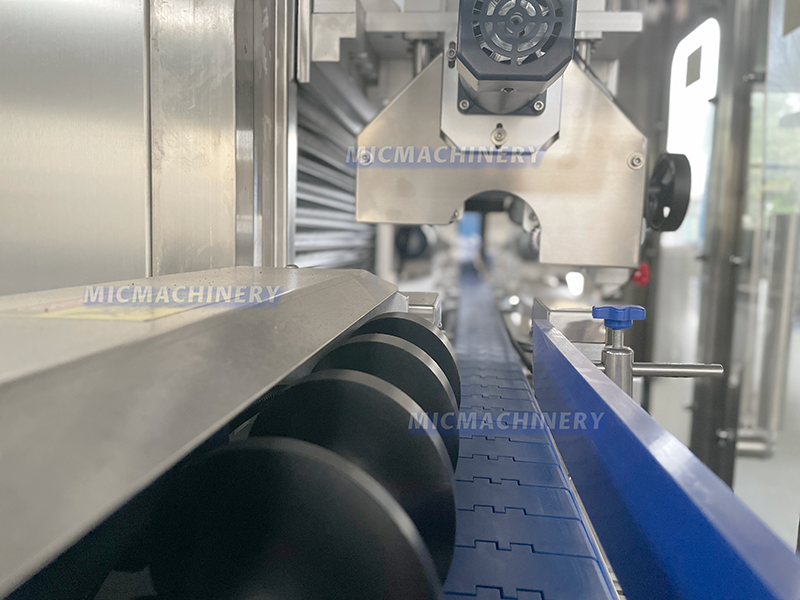

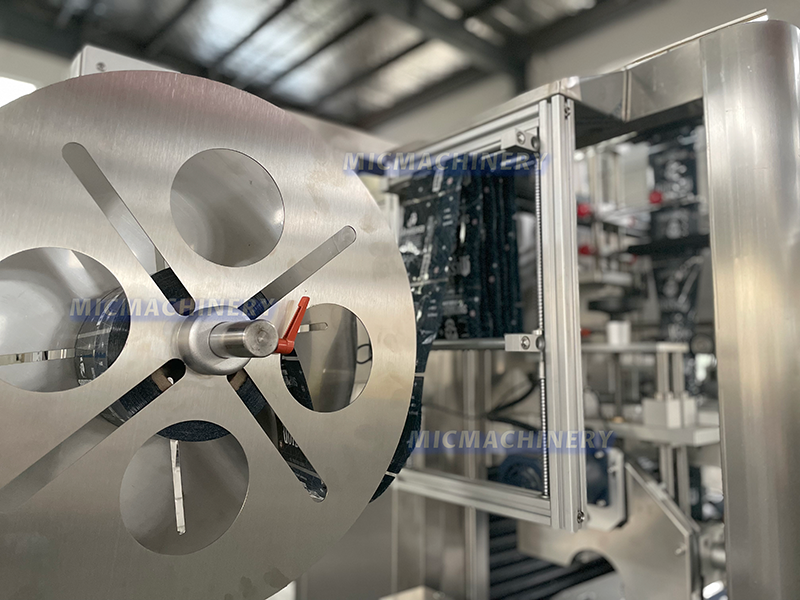

Shrink sleeve applicators are machines used in the packaging industry for the application of shrink sleeves onto a variety of containers, such as bottles, cans, and jars. The sleeves are made of a heat-shrinkable plastic material that conforms to the shape of the container when heat is applied, resulting in a tight and secure fit.

Shrink sleeve applicators are highly versatile and can be used for a wide range of products, from food and beverage to cosmetics and pharmaceuticals. They offer many benefits to manufacturers, including the ability to create eye-catching packaging designs, protect products during transit, and provide tamper-evident seals.

In this article, we will explore the key features and benefits of shrink sleeve applicators

1. High accuracy: Shrink sleeve applicators are equipped with advanced sensors that ensure accurate sleeve placement on the container.

2. Customizable: These machines can handle a wide variety of sleeve sizes and shapes, and can be customized to meet the specific requirements of different products and packaging formats.

3. Easy to use: Most shrink sleeve applicators have a user-friendly interface that makes it easy to set up and operate the machine.

4. High speed: These machines can apply sleeves at a high speed, which increases the efficiency of the packaging process.

Benefits:

1. Enhanced product visibility: Shrink sleeve applicators create a 360-degree coverage on the product container, which provides ample space for branding and product information. This makes it easier for consumers to identify and choose the product.

2. Tamper-evident packaging: Shrink sleeves can be designed with tamper-evident features that ensure the product is safe and secure for consumption.

3. Protects the product: Shrink sleeves provide a layer of protection to the product from external factors such as dust, moisture, and UV rays.

4. Cost-effective: Shrink sleeve applicators are cost-effective in terms of the materials used for sleeves and the efficiency of the application process. This can result in a lower cost-per-unit for packaging.

|

Input Power |

Input Power |

|

Input Voltage |

3,380 1220VAC |

|

Production Efficiency |

150 bottle / min |

|

Size Of Host Machine |

L2000mm*W850mm*H2000mm |

|

Applicable Diameter Of Bottle Body |

30-55mm |

|

Applicable Length Of Label |

30-150mm |

|

Applicable Thickness Of Label |

0.03-0. 13mm |

|

Applicable Intemal Diameter Of Paper Tube |

5"-10" free adjustment |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment