- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

A semi-automatic soft drink packaging machine is a type of machinery used in the beverage industry to package soft drinks in bottles or cans. These machines are designed to automate certain aspects of the packaging process while still requiring some manual intervention from the operator.

Semi-automatic soft drink packaging machines are ideal for small to medium-scale beverage production operations that do not require the high-speed output of fully automated machines. They are also suitable for operations where multiple types of packaging materials or sizes are used, as the operator can easily adjust the machine settings to accommodate different products.

The key advantage of semi-automatic soft drink packaging machines is their flexibility. These machines can be used for a wide range of soft drink packaging applications, including filling, capping, labeling, and sealing. They are also typically more affordable and easier to maintain than fully automated machines.

While semi-automatic soft drink packaging machines still require some operator intervention, they are often equipped with features such as electronic controls and sensors that help to streamline the packaging process and ensure accuracy and consistency. Additionally, they can be easily integrated into existing packaging lines and workflows.

Overall, semi-automatic soft drink packaging machines are an important tool for small to medium-scale beverage manufacturers who need to package soft drinks efficiently and effectively, without the high costs and complexity associated with fully automated machines.

Semi-automatic soft drink packaging machines are ideal for small to medium-scale beverage production operations that do not require the high-speed output of fully automated machines. They are also suitable for operations where multiple types of packaging materials or sizes are used, as the operator can easily adjust the machine settings to accommodate different products.

The key advantage of semi-automatic soft drink packaging machines is their flexibility. These machines can be used for a wide range of soft drink packaging applications, including filling, capping, labeling, and sealing. They are also typically more affordable and easier to maintain than fully automated machines.

While semi-automatic soft drink packaging machines still require some operator intervention, they are often equipped with features such as electronic controls and sensors that help to streamline the packaging process and ensure accuracy and consistency. Additionally, they can be easily integrated into existing packaging lines and workflows.

Overall, semi-automatic soft drink packaging machines are an important tool for small to medium-scale beverage manufacturers who need to package soft drinks efficiently and effectively, without the high costs and complexity associated with fully automated machines.

MIC Semi-Automatic Soft Drink Packaging Machine: Your Ideal Solution for Efficiency

At Micmachinery, we pride ourselves on delivering innovative and efficient solutions for beverage manufacturers. Our MIC Semi-Automatic Soft Drink Packaging Machine is specifically designed to streamline the packaging process, making it a perfect choice for businesses seeking precision, quality, and affordability.

Whether you are producing soft drinks for local markets or larger distributions, this machine offers unparalleled efficiency and reliability. Let’s explore its features and capabilities.

Why Choose the MIC Semi-Automatic Soft Drink Packaging Machine?

1. Cost-Effective Solution

One of the standout benefits of this equipment is its affordability. We understand that every business operates with budget considerations, and this machine provides a balance of quality and performance. If you're searching for information on soft drink filling machine price, you'll find this model competitively priced without compromising functionality.

2. Reliable Packaging Performance

This soft drink packaging machine is tailored to handle various beverage types, ensuring consistent packaging quality. From carbonated drinks to flavored beverages, the machine delivers precise performance with every operation.

3. Versatile Applications

The soft drink canning machine is engineered to accommodate cans and bottles of different sizes, providing versatility for businesses that offer a variety of products. This adaptability enables manufacturers to cater to diverse consumer preferences.

4. Semi-Automatic Operation

Designed for ease of use, the machine combines manual control with automated features, giving operators the flexibility to manage production while ensuring accuracy. The semi-automatic system simplifies processes without requiring extensive technical expertise.

5. Durable and Hygienic Construction

Constructed with high-quality stainless steel, the machine guarantees hygiene and durability. It complies with food safety standards, making it an excellent choice for soft drink production facilities focused on maintaining product integrity.

Key Features

High Precision Filling System

The machine's filling system ensures accurate liquid measurements, minimizing waste and maintaining consistent product quality.

Compact and Space-Saving Design

Ideal for businesses with limited production space, this machine integrates seamlessly into existing workflows.

User-Friendly Interface

The simple controls make operation intuitive, allowing your team to focus on production efficiency.

Low Maintenance Requirements

Built to last, the machine requires minimal maintenance, reducing downtime and increasing productivity.

Applications

This machine is perfect for:

Small to medium-scale soft drink manufacturers.

Beverage plants expanding into canned soft drink production.

Businesses producing carbonated drinks, flavored waters, or energy drinks.

Micmachinery: Your Trusted Partner in Beverage Equipment

At Micmachinery, we are dedicated to helping businesses achieve their production goals with state-of-the-art equipment. Our MIC Semi-Automatic Soft Drink Packaging Machine exemplifies our commitment to quality, efficiency, and customer satisfaction.

If you're looking for a reliable, cost-effective solution for your soft drink production line, this machine is an excellent investment. With its precise performance and competitive soft drink filling machine price, it’s designed to meet the demands of modern beverage manufacturing.

Contact Us Today

Discover how the MIC Semi-Automatic Soft Drink Packaging Machine can revolutionize your production process. Contact Micmachinery now for detailed information and pricing. Let us help you grow your business with the right tools and expertise.

At Micmachinery, we pride ourselves on delivering innovative and efficient solutions for beverage manufacturers. Our MIC Semi-Automatic Soft Drink Packaging Machine is specifically designed to streamline the packaging process, making it a perfect choice for businesses seeking precision, quality, and affordability.

Whether you are producing soft drinks for local markets or larger distributions, this machine offers unparalleled efficiency and reliability. Let’s explore its features and capabilities.

Why Choose the MIC Semi-Automatic Soft Drink Packaging Machine?

1. Cost-Effective Solution

One of the standout benefits of this equipment is its affordability. We understand that every business operates with budget considerations, and this machine provides a balance of quality and performance. If you're searching for information on soft drink filling machine price, you'll find this model competitively priced without compromising functionality.

2. Reliable Packaging Performance

This soft drink packaging machine is tailored to handle various beverage types, ensuring consistent packaging quality. From carbonated drinks to flavored beverages, the machine delivers precise performance with every operation.

3. Versatile Applications

The soft drink canning machine is engineered to accommodate cans and bottles of different sizes, providing versatility for businesses that offer a variety of products. This adaptability enables manufacturers to cater to diverse consumer preferences.

4. Semi-Automatic Operation

Designed for ease of use, the machine combines manual control with automated features, giving operators the flexibility to manage production while ensuring accuracy. The semi-automatic system simplifies processes without requiring extensive technical expertise.

5. Durable and Hygienic Construction

Constructed with high-quality stainless steel, the machine guarantees hygiene and durability. It complies with food safety standards, making it an excellent choice for soft drink production facilities focused on maintaining product integrity.

Key Features

High Precision Filling System

The machine's filling system ensures accurate liquid measurements, minimizing waste and maintaining consistent product quality.

Compact and Space-Saving Design

Ideal for businesses with limited production space, this machine integrates seamlessly into existing workflows.

User-Friendly Interface

The simple controls make operation intuitive, allowing your team to focus on production efficiency.

Low Maintenance Requirements

Built to last, the machine requires minimal maintenance, reducing downtime and increasing productivity.

Applications

This machine is perfect for:

Small to medium-scale soft drink manufacturers.

Beverage plants expanding into canned soft drink production.

Businesses producing carbonated drinks, flavored waters, or energy drinks.

Micmachinery: Your Trusted Partner in Beverage Equipment

At Micmachinery, we are dedicated to helping businesses achieve their production goals with state-of-the-art equipment. Our MIC Semi-Automatic Soft Drink Packaging Machine exemplifies our commitment to quality, efficiency, and customer satisfaction.

If you're looking for a reliable, cost-effective solution for your soft drink production line, this machine is an excellent investment. With its precise performance and competitive soft drink filling machine price, it’s designed to meet the demands of modern beverage manufacturing.

Contact Us Today

Discover how the MIC Semi-Automatic Soft Drink Packaging Machine can revolutionize your production process. Contact Micmachinery now for detailed information and pricing. Let us help you grow your business with the right tools and expertise.

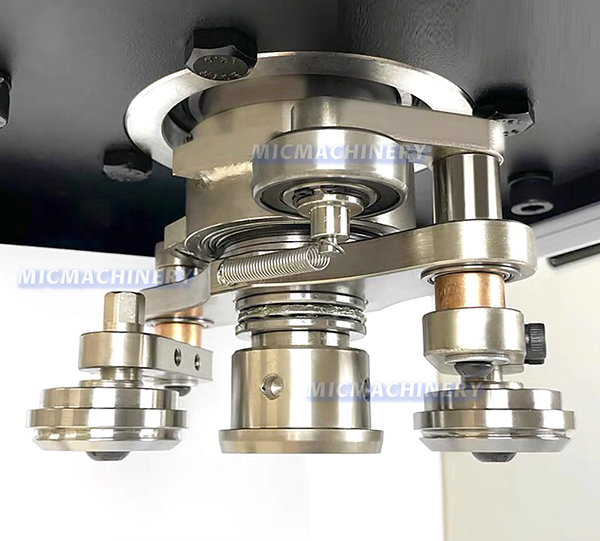

Capping Station

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

Work flow of capping machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal device rotates at high speed and spins the cap efficiently.

|

Weight |

52kg |

|

Voltage |

220V 50Hz |

|

Packaging Type |

CANS, Bottles |

|

Dimension |

255*455*608mm |

|

Motor power |

0.55KW |

|

Filling speed |

30 cans each minute |

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment