- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Semi-automatic soft drink filling machines are ideal for small to medium-scale beverage production operations that do not require the high-speed output of fully automated machines. They are also suitable for operations where multiple types of packaging materials or sizes are used, as the operator can easily adjust the machine settings to accommodate different products.

The key advantage of semi-automatic soft drink filling machines is their flexibility. These machines can be used for a wide range of soft drink filling applications, including carbonated and non-carbonated beverages, as well as various bottle or can sizes. They are also typically more affordable and easier to maintain than fully automated machines.

While semi-automatic soft drink filling machines still require some operator intervention, they are often equipped with features such as electronic controls and sensors that help to streamline the filling process and ensure accuracy and consistency. Additionally, they can be easily integrated into existing production lines and workflows.

Overall, semi-automatic soft drink filling machines are an important tool for small to medium-scale beverage manufacturers who need to fill bottles or cans with soft drinks efficiently and effectively, without the high costs and complexity associated with fully automated machines.

At Micmachinery, we are dedicated to providing advanced solutions for the beverage industry. The MIC Semi-Automatic Soft Drink Filling Machine is an ideal choice for small to medium-sized soft drink producers looking for an efficient, versatile, and cost-effective filling solution. Engineered with precision, this machine ensures reliable performance, making it a smart investment for beverage businesses worldwide.

Why Choose the MIC Semi-Automatic Soft Drink Filling Machine?

1. Competitive Pricing

For businesses concerned about the soft drink filling machine price, this model offers exceptional value. Combining affordability with top-tier performance, it is designed to deliver optimal results while staying within your budget.

2. Flexible Capacity

This soft drink filling machine can handle a production capacity of 200-800 containers per hour, making it perfect for growing businesses. Whether you’re launching a new line or scaling operations, this machine adapts seamlessly to your production needs.

3. Semi-Automatic Operation for Better Control

The semi-automatic design provides a balance of efficiency and user control. Operators can manage the process with ease, ensuring consistent and precise filling with every cycle.

4. Versatile Packaging Options

Compatible with various container sizes and types, this machine is ideal for businesses that require a flexible soft drink packaging machine. Whether you’re filling bottles, cans, or custom containers, this machine meets diverse packaging requirements.

5. Durability and Hygiene

Built with high-quality, food-grade materials, the machine ensures hygiene and long-term reliability. It’s engineered to withstand continuous operation while maintaining the highest standards of cleanliness.

Key Features of the MIC Semi-Automatic Soft Drink Filling Machine

Accurate Filling Mechanism: Ensures precise filling volumes, minimizing waste and enhancing product consistency.

Compact Design: Its space-saving footprint makes it an excellent choice for facilities with limited space.

Easy Maintenance: Designed for minimal downtime, the machine’s components are easy to clean and maintain.

User-Friendly Interface: Simple controls and ergonomic design enable smooth operation, even for operators with minimal training.

Energy Efficiency: The machine operates with minimal power consumption, reducing operational costs over time.

Applications

The MIC Semi-Automatic Soft Drink Filling Machine is ideal for:

Small and medium-sized beverage manufacturers.

Producers of carbonated beverages, flavored drinks, and sparkling water.

Businesses expanding into bottled or canned soft drinks.

Its compatibility with a variety of packaging options ensures it integrates seamlessly into your production line alongside other soft drink packaging machine components.

Why Partner with Micmachinery?

At Micmachinery, we understand the unique needs of the beverage industry. Our soft drink filling machines are designed to maximize efficiency, minimize costs, and ensure product quality. The MIC Semi-Automatic Soft Drink Filling Machine exemplifies our commitment to innovation, reliability, and customer satisfaction.If you’re seeking a high-performing machine at an affordable soft drink filling machine price, this model is the perfect choice. Its robust design, user-friendly features, and flexible capabilities make it a standout solution for soft drink production.

Contact Us Today

Ready to take your beverage production to the next level? Contact Micmachinery to learn more about the MIC Semi-Automatic Soft Drink Filling Machine. Our team is here to answer your questions and provide customized solutions for your business needs.

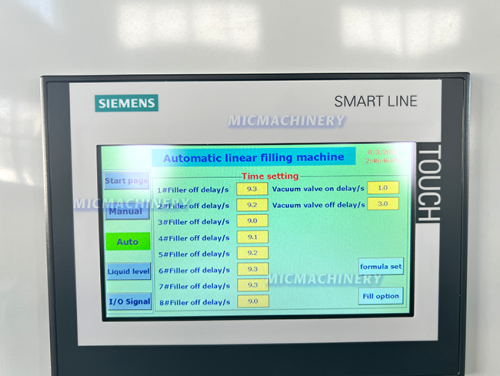

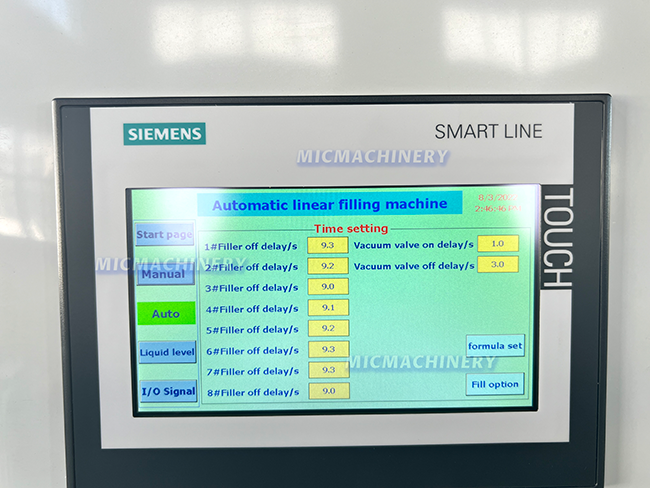

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment