- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Welcome to Micmachinery, your trusted manufacturer and supplier of high-quality beverage processing equipment. We are proud to present our MIC Semi Automatic Glass Bottle Soda Filling Machine, designed to optimize your soda bottling process with precision and efficiency. This machine operates at a speed of 200-800 BPH, making it an ideal choice for small to medium-sized production facilities looking to enhance their bottling capabilities.

Features of the MIC Semi Automatic Glass Bottle Soda Filling Machine

1. Robust Construction: Built with high-grade stainless steel, our glass bottle soda filling machine ensures durability and resistance to corrosion, making it suitable for the demanding environment of beverage production.

2. Efficient Filling Mechanism: The semi-automatic design allows for precise filling, minimizing product loss and ensuring consistent quality. The machine's advanced control system maintains accurate filling levels, which is crucial for achieving optimal product integrity.

3. Versatile Bottle Compatibility: This machine is designed to accommodate various sizes and shapes of glass bottles, making it a versatile addition to any production line. Whether you're bottling carbonated drinks or flavored sodas, our filling machine adapts to your needs.

4. User-Friendly Operation: Featuring an intuitive control panel, the semi automatic glass bottle soda filling machine simplifies the operation process. Operators can easily adjust settings, monitor performance, and troubleshoot issues, ensuring smooth operation throughout the production cycle.

5. High-Speed Performance: With a capacity ranging from 200 to 800 bottles per hour, our soda bottling machine significantly increases your production efficiency. This high-speed performance is complemented by a compact design that fits seamlessly into your existing production line.

6. Hygienic Design: Our machine prioritizes hygiene with easy-to-clean surfaces and minimal crevices, meeting international food safety standards. This feature is vital for maintaining the quality and safety of your beverages.

7. Energy Efficient: Designed with energy-saving technologies, our glass bottle soda filling machine helps reduce operational costs while maintaining high performance. This commitment to sustainability reflects our dedication to environmentally friendly manufacturing practices.

8. Comprehensive Support: At Micmachinery, we offer ongoing technical support and maintenance services to ensure your machine operates at peak efficiency. Our experienced team is always ready to assist you with any inquiries or challenges you may encounter.

In conclusion, the MIC Semi Automatic Glass Bottle Soda Filling Machine is an essential investment for any beverage manufacturer looking to enhance their production capabilities. With its robust construction, efficient filling mechanism, and user-friendly design, it stands out as a top choice for those in the soda bottling industry. Choose Micmachinery for reliable, high-quality solutions that meet your specific needs.

semi-automatic glass bottle soda filling machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

The semi-automatic glass bottle soda filling machine represents a significant leap forward from manual processes, incorporating automation to enhance productivity and efficiency. It combines the expertise and skill of the operator with automated functionalities to achieve consistent and accurate soda filling results. This machine bridges the gap between full automation and manual control, offering an ideal solution for manufacturers seeking improved efficiency without compromising their ability to make adjustments or accommodate diverse bottle sizes and shapes.

Flexibility and customization are key advantages of the semi-automatic glass bottle soda filling machine. It allows manufacturers to adapt to different bottle sizes, enabling the filling of various capacities and shapes. The machine's adjustable settings and operator control provide the flexibility to fine-tune the filling process, ensuring precise dosing and maintaining consistent fill levels. This adaptability allows producers to meet specific customer preferences, explore new product offerings, and respond to market demands promptly.

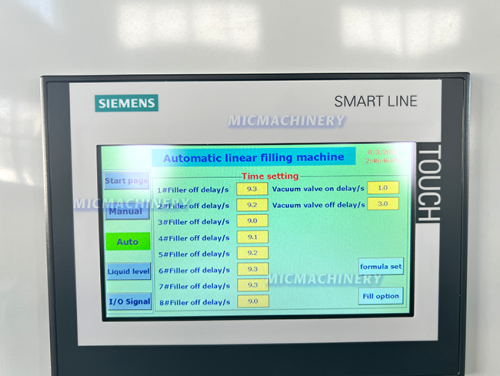

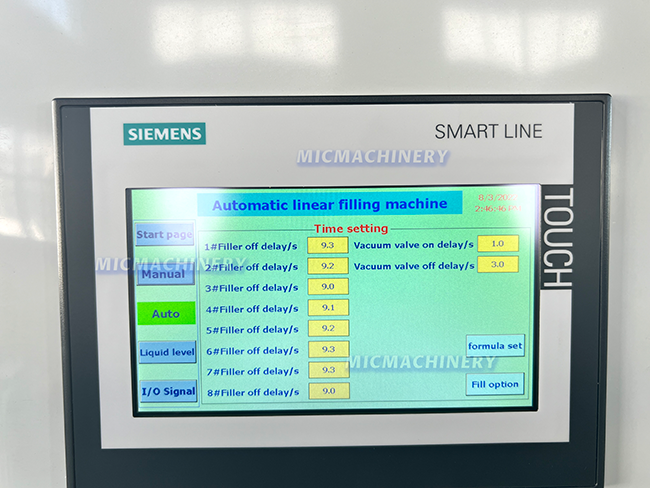

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the soda into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for soda, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment