- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Technical Parameters

◆ Process Features

* Its shape is simple and beautiful, its structure is novel and unique, and its maintenance is convenient.

* Pneumatic expansion supporting membrane coil, electronic induction membrane transport, smooth film delivery, fast membrane replacement.

* Schneider servo motor control system is stable and reliable.

* Lengthening the bottle conveyer belt is beneficial to the sorting of bottles, effectively increasing the number of membrane poles, reducing the linear speed of the conveyor chain and increasing the tolerance of the equipment.

* The contraction chamber adopts the unique circulation air transportation technology, which greatly improves the shrinkage effect. The structure is reasonable, thermal insulation, temperature control accuracy is high, shrink packaging effect is better.

* 10 inch super large screen, friendly interface and quick parameter setting.

* More than 90% of electrical components are imported high-quality brands, stable and reliable.

* The whole machine adopts energy-saving technology design, saving 35% energy consumption, low carbon and environmental protection.

◆ Main Components and Functions

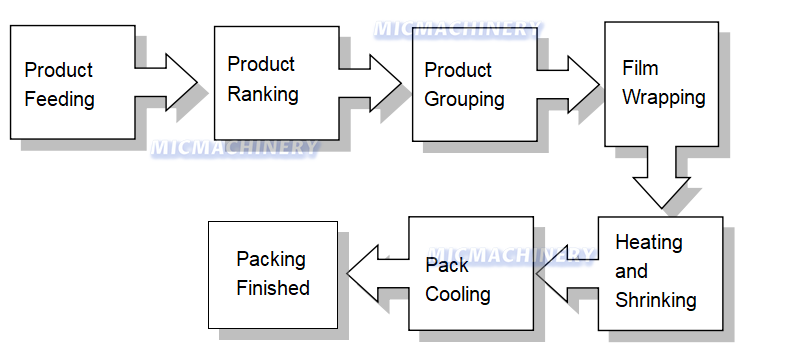

The whole equipment consists of bottle conveyor belt, packing machine, heat shrinkable machine, electrical control, pneumatic control and so on.

1 .Packing Machine

The packing machine is mainly composed of frame, bottle distributing mechanism, bottle pushing mechanism, film releasing mechanism, film wrapping mechanism, etc.

A.The bottle feeding mechanism is responsible for transporting PET bottles to the bottle feeding mechanism, which is divided into two parts: front transportation and rear transportation.

B.The bottling mechanism is responsible for dividing the PET bottles according to the packaging requirements, so as to achieve the film wrapping.

C.The bottle pushing mechanism is responsible for pushing the grouped PET bottles so as to achieve the film wrapping.

D.The film rewinding is responsible for the supply of bottles with PET Film after grouping.

E.Wrapping film: automatically set the supply length of the shrink film according to the size of the packaging, and automatically wrap the film in the process of moving the product forward.

2. Heat Shrink Machine

The heat shrinkable machine consists of three parts: heating shrinkage, cooling shaping and product conveying.

A.Heating and Shrinking: The shrink machine heat and contract the wrapped package, so that the film is contracted evenly at the set temperature, close to the surface of the package, and wrap the package tightly to achieve the purpose of the package.

B.Cooling and Pitching: It is responsible for rapidly cooling the film on the surface of the finished package, so that the film can rapidly become a high strength state for easy handling.

The seal and shrink packaging machine is a versatile and efficient piece of equipment widely used in various industries for packaging products securely. Combining sealing and shrink wrapping functions into a single unit, these machines offer a streamlined and cost-effective solution for packaging operations.

Seal and shrink packaging machine are designed to deliver reliable performance and consistent results. They are capable of sealing products in a protective layer of film using heat or pressure, ensuring a secure and tamper-evident package. Subsequently, the shrink wrapping function activates the film, causing it to shrink tightly around the product, creating a professional-looking package with enhanced protection and presentation.

As part of shrink packaging equipment, seal and shrink packaging machines play a crucial role in optimizing packaging processes and increasing efficiency. They are suitable for a wide range of product types and sizes, from individual items to bulk quantities, making them versatile assets in packaging operations.

When considering purchasing a seal and shrink packaging machine, it's essential to assess various factors, including the shrink packaging machine price. Prices can vary depending on factors such as machine capacity, features, and brand reputation. It's advisable to invest in a machine that offers the necessary functionalities while remaining cost-effective in the long run.

Choosing a reputable shrink packaging machine manufacturer is also essential to ensure product quality, reliability, and after-sales support. Established manufacturers often provide warranty coverage, technical assistance, and spare parts availability, which are crucial for maintaining machine performance and minimizing downtime.

The heat shrink film packing machine, another term for seal and shrink packaging machine, emphasizes the use of heat shrink film as the primary packaging material. Heat shrink film offers excellent clarity, strength, and shrinkability, ensuring a tight and secure package that protects products during transit and storage.

Additionally, shrinkable packing machine refer to the broader category of equipment that includes seal and shrink packaging machines. These machines utilize shrinkable materials, such as shrink film or shrink wrap, to package products securely and efficiently.

In summary, the seal and shrink packaging machine is a versatile and indispensable asset in modern packaging operations. Alongside other shrink packaging equipment, it ensures product integrity, protection, and presentation, contributing to enhanced brand image and customer satisfaction. By investing in quality equipment from reputable manufacturers, businesses can optimize their packaging processes and maintain a competitive edge in the market.

|

Dimensions(standard) |

12000*1530*2500 |

Shrink channel size |

2500*650*450 |

|

shrink film material |

PE |

Shrink film thickness |

0.03-0.15mm |

|

Heat shrink furnace temperature |

160 - 260° |

Gas consumption |

100-120NL/min |

|

equipment power |

40KW |

Voltage requirements |

380V/50-60HZ |

|

equipment weight |

4100kg |

conveying height |

950-1000mm |

ROY-25P electrical configuration

|

No |

Name |

Model |

Amount |

Origin |

Brand |

|

1 |

10 inch Touch Screen |

IT7100E |

1 |

China |

Inovance |

|

2 |

PLC |

AM402-CPU1608TN |

1 |

China |

Inovance |

|

3 |

PLC Power module |

GL10-PS2 |

1 |

China |

Inovance |

|

4 |

Frequency converter |

MD200T0.75B |

2 |

China |

Inovance |

|

5 |

Frequency converter |

MD200T1.5B |

3 |

China |

Inovance |

|

6 |

Servo motor drive |

SV660NT5R4I |

1 |

China |

Inovance |

|

7 |

Servo motor drive |

SV660NS5R5I |

2 |

China |

Inovance |

|

8 |

Servo motor |

MS1H3-13C15CD-A331Z |

1 |

China |

Inovance |

|

9 |

Servo motor |

MS1H1-75B30CB-A331Z |

2 |

China |

Inovance |

|

10 |

film tightening cylinder |

4HV310-08 |

1 |

ChinaTaiwan |

Airtac |

|

11 |

Bottle pressing cylinder |

DNB50N25 |

1 |

ChinaTaiwan |

Airtac |

|

12 |

Film out, pour bottle photoelectric |

BMS2M-MDT-P |

2 |

South korea |

Autonics |

|

13 |

Reset photoelectric |

PR12-4DP |

1 |

South korea |

Autonics |

|

14 |

High power contactor |

LC1D95 |

2 |

France |

Schneider |

|

15 |

Low power contactor |

LC1N0910 |

3 |

France |

Schneider |

|

16 |

Low power contactor |

LC1N1810 |

1 |

France |

Schneider |

|

17 |

Intermediate relay |

24VDC |

11 |

France |

Schneider |

|

18 |

4P power switch |

iC65N C20A |

2 |

France |

Schneider |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment