- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Plastic Bottle Making Machine: High-Efficiency PET Blowing Solutions

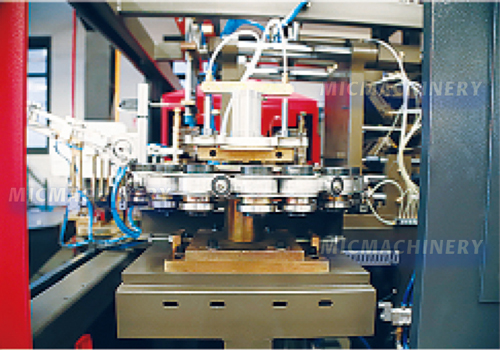

A plastic bottle making machine is a critical piece of equipment in the manufacturing of PET bottles for industries such as beverages, cosmetics, pharmaceuticals, and household products. Designed for precision and efficiency, this machine ensures high-quality bottle production with advanced automation and energy-saving technology. Whether you need a PET blowing machine for small-scale operations or a high-speed system, investing in the right equipment is key to optimizing production efficiency.

How a PET Blowing Machine Works

A PET blowing machine follows a series of mechanical steps to transform PET preforms into bottles of various sizes and shapes. The process includes:

- Preform Heating – The plastic bottle making machine heats the PET preforms uniformly using infrared heating, ensuring optimal elasticity for forming.

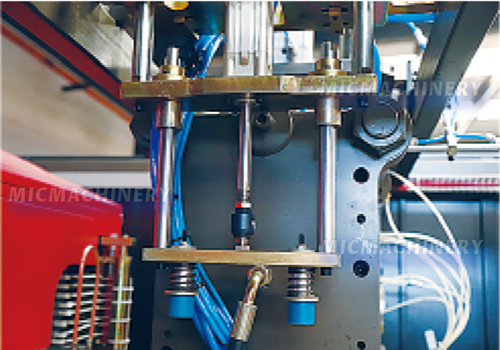

- Stretching and Blowing – A stretching rod extends the heated preform while high-pressure air inflates it into a mold, shaping the bottle.

- Cooling and Ejection – The newly formed PET bottle is cooled, solidified, and automatically ejected from the mold for further processing.

-

Key Features of a Plastic Bottle Making Machine

A high-quality plastic bottle making machine offers several essential features to maximize production efficiency and bottle quality:

- Energy-Efficient Heating System – Optimized infrared heating minimizes energy consumption while maintaining precise temperature control.

- Multi-Cavity Molds – Increases output by allowing multiple bottles to be produced simultaneously.

- Customizable Bottle Shapes and Sizes – Adjustable mold designs enable the production of a variety of PET bottles.

- High-Speed Production – Advanced PET blowing machines can manufacture thousands of bottles per hour, making them ideal for large-scale production.

-

Fully Automatic Plastic Bottle Making Machine Price Considerations

The fully automatic plastic bottle making machine price varies based on several factors, including:

- Production Capacity – Higher output machines with multi-cavity molds tend to have a higher price.

- Automation Level – Fully automatic systems with robotic operations and smart controls cost more than semi-automatic models.

- Material and Build Quality – Machines made from high-grade stainless steel and durable components offer better longevity and efficiency.

- Additional Features – Advanced options such as servo motor control, air recovery systems, and intelligent monitoring increase the investment cost but improve efficiency.

-

Advantages of Using a PET Blowing Machine

- Cost-Effective Production – Reduces labor costs while increasing output and efficiency.

- Consistent Bottle Quality – Ensures uniform thickness, shape, and durability.

- Versatile Applications – Capable of producing PET bottles for beverages, edible oils, cosmetics, and pharmaceuticals.

- Eco-Friendly Manufacturing – Supports the use of recycled PET materials, promoting sustainable production.

A plastic bottle making machine is a must-have for any manufacturer looking to produce high-quality PET bottles efficiently. Whether you are searching for an entry-level PET blowing machine or evaluating the fully automatic plastic bottle making machine price, investing in the right equipment will enhance your production capabilities and ensure long-term profitability.

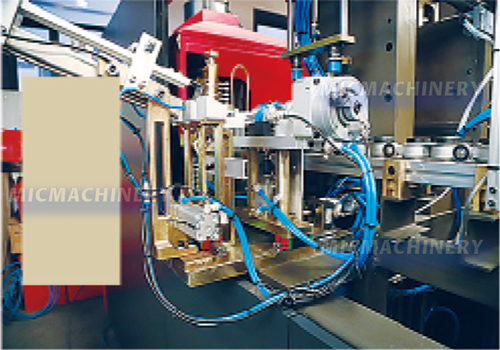

It has many advantages including cover a little area, high efficiency, energy conservation and cost, etc.

The bottle blowing machines apply to below 1.5L bottles for mineral water, beverage, condiment cosmetic and pharmaceutical, etc.

A blow molding machine is a specialized industrial device used for manufacturing plastic bottles, containers, and hollow packaging products by inflating heated plastic into a mold cavity. It is widely used in industries such as beverages, food, pharmaceuticals, and cosmetics, offering high efficiency and precision in bottle production.

Blow molding machines operate using different methods, including extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM). The process involves heating plastic material (such as PET or HDPE), forming a parison or preform, and then expanding it with compressed air inside a mold to create the final shape.

Modern blow molding machines are equipped with advanced automation, precise temperature control, and high-speed production capabilities, ensuring uniform quality, energy efficiency, and reduced material waste. Jiangsu Mic Machinery specializes in manufacturing high-performance blow molding machines that meet the needs of customized bottle production and large-scale manufacturing, providing reliable solutions for the packaging industry.

| Technical parameters: | |

| Model&Name | CY-II-1.5L-1500A |

| Overall Dimensions(mm) Length*Width*Height(mm) |

Main machine: 2900*1700*2200

Elevator: 2000*1200*2700

|

| Weight | 2(ton) |

| No. of Cavities | 2(cav.) |

| Cavity Pitch | 140(mm) |

| Max. Capacity | 2.5(litre) |

| Heating Pitch | 140(mm) |

| No. of Perform Holders | 40(PCS) |

| Preform Neck (inner dia.) | 26~50(mm) |

| Preform Height (max) | 170(mm) |

| Bottle Inner Diameter (max) | 130(mm) |

| Bottle Height (max) | 320(mm) |

| No. of Heating Ovens | 1(unit) |

| No. of Infrared Lamps | 32(pcs) |

| Max. Heating Power | 25(kw) |

| Specified Power Consumption | 38(kw) |

| Voltage | 380V(50/60hz) |

|

Theoretical Production

(Based on 150ml; Preform: 28g; Round Bottle)

|

1500(pcs/h) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment