- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

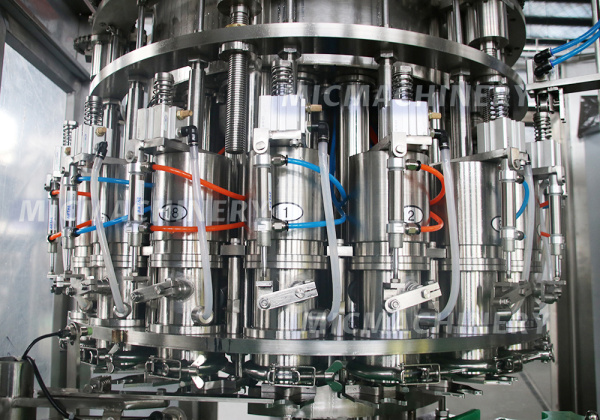

MIC-18-6 rotary type cooking edible oil glass bottle filling capping machine adopts volumetric type quantitative filling system which is applicable for vegetable oil , cooking oil , olive oil, edible oil, sunflower oil, peanut oil etc liquid like oil products.

Features:

1.Volumetric type quantitative filling can ensure high precision filling, do not waste materials. To make the filling process is stable and high efficient.

2.The structural design of each part fully considers the health requirements, the filling cylinder,filling valve and parts in contact with the material are made of stainless steel 304, with good corrosion resistance.

3.This machine is equipped with a set of adjustment device, so that customers can fill 500ml~2000ml bottles without changing the measuring cup, only adjust the measuring cup capacity. No bottle no filling function.

4.The position turning block of the filling valve turns the position and opens the valve under the action of another cylinder. Cylinder backblowing anti-drip device.

5.It is mainly used for oil bottle filling and capping. Its structure is advanced, stable, reliable, safe operation, convenient maintenance, the use of frequency conversion speed control, high production efficiency, is the ideal equipment for big and medium sized food and oil factory.

The mustard oil bottle packing machine price is a key consideration for businesses looking to invest in efficient packaging solutions. This machine is designed to handle the specific requirements of mustard oil, which includes managing its viscosity and ensuring accurate fills. The equipment is equipped with advanced features such as adjustable filling volumes and automated capping systems to enhance efficiency and reduce labor costs.

The oil bottle packing process with this machine is highly streamlined. It integrates filling, capping, and labeling functions to provide a complete solution for packing mustard oil. This integration helps in minimizing manual intervention, thereby increasing production speed and consistency. The machine’s design ensures minimal spillage and wastage, which contributes to cost savings and improved product quality.

Additionally, the olive oil bottling equipment shares similar technological advancements and can be adapted for packing various types of oils, including olive oil. This versatility ensures that businesses can use the same machinery for different products, providing flexibility and cost-effectiveness. The machine’s precision and efficiency in handling delicate oils like olive oil demonstrate its capability to maintain high-quality standards across different oil types.

Overall, the mustard oil bottle packing machine price reflects the advanced technology and features that enhance productivity and maintain product integrity. With its efficient oil bottle packing process and adaptability for olive oil bottling equipment, it represents a valuable investment for businesses aiming to improve their packaging operations and ensure high-quality output.

Volumetric type quantitative filling system

Filling part working principle: this machine adopts non-contact quantitative filling. Open the measuring cup control valve, feed oil to the measuring cup according to the adjusted flow, and the bottle is conveyed into the filling machine by the conveyor belt, screw and dial wheel. At the same time, the time control is used to close the measuring cup control valve after accurate measurement. After the filling process is completed, the cylinder acts to blow the last remaining oil from the valve port into the bottles, so as to achieve the effect of no drip leakage. Then send to the capping machine to complete the screwing.

Plastic cap screwing system

The motor transmits the power to the main shaft through the transmission device, so that the turntable rotates. Because the central gear does not rotate, the rotary cap rotates because of the rotation of the gear of the rotary cap shaft. When the machine sealing, the cover through the automatic cover falling device, cover falling guide rail, there is a bottle into the cover plate, no bottle then no cover, when the rotation of the cap side moving down, rotation (pressure) cap under the action of the CAM to complete cover. Then by the drawing wheel into bottle delivery.

Liquid nitrogen doser

In order to extend the shelf life and freshness of the oil, we will suggest our customer to add this liquid nitrogen doser to work with filling machine.

|

Power |

3Kw |

|

Filling heads |

18piece |

|

Sealing heads |

6piece |

|

Filling volume range |

0.5-2L |

|

Production capacity |

3000-6000CPH based on 500ml |

|

Filling temperature |

room temperature |

|

Bottle diameter range |

Ф60-120MM |

|

Bottle height |

180-380MM |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

0.8-1.0m³/min |

|

Dimension |

2400×1400×2500mmm |

|

Weight |

2500Kg |

|

Name |

Brand |

|

Touch screen |

Siemens (Germany) |

|

Buttons |

Schneider (France) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Germany) |

|

Frequency changer |

Schneider (France) |

|

Breaker |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment